PDF Publication Title:

Text from PDF Page: 106

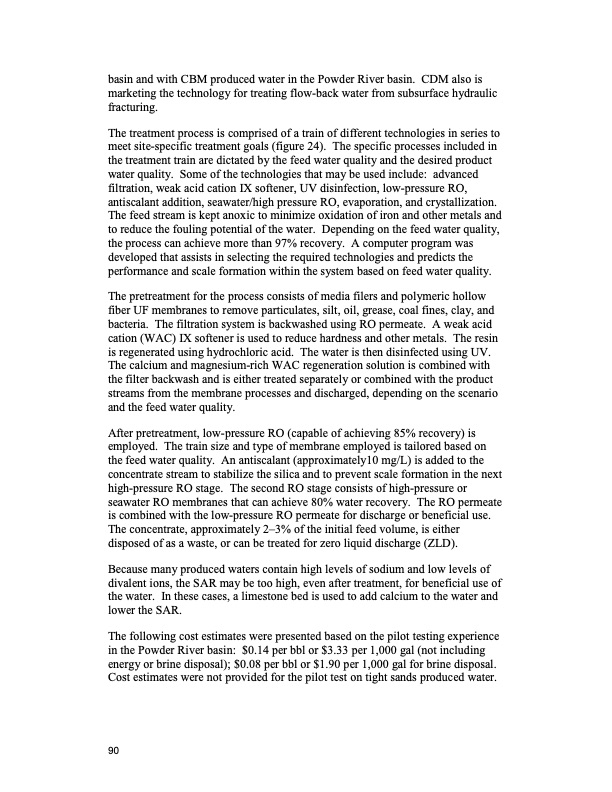

basin and with CBM produced water in the Powder River basin. CDM also is marketing the technology for treating flow-back water from subsurface hydraulic fracturing. The treatment process is comprised of a train of different technologies in series to meet site-specific treatment goals (figure 24). The specific processes included in the treatment train are dictated by the feed water quality and the desired product water quality. Some of the technologies that may be used include: advanced filtration, weak acid cation IX softener, UV disinfection, low-pressure RO, antiscalant addition, seawater/high pressure RO, evaporation, and crystallization. The feed stream is kept anoxic to minimize oxidation of iron and other metals and to reduce the fouling potential of the water. Depending on the feed water quality, the process can achieve more than 97% recovery. A computer program was developed that assists in selecting the required technologies and predicts the performance and scale formation within the system based on feed water quality. The pretreatment for the process consists of media filers and polymeric hollow fiber UF membranes to remove particulates, silt, oil, grease, coal fines, clay, and bacteria. The filtration system is backwashed using RO permeate. A weak acid cation (WAC) IX softener is used to reduce hardness and other metals. The resin is regenerated using hydrochloric acid. The water is then disinfected using UV. The calcium and magnesium-rich WAC regeneration solution is combined with the filter backwash and is either treated separately or combined with the product streams from the membrane processes and discharged, depending on the scenario and the feed water quality. After pretreatment, low-pressure RO (capable of achieving 85% recovery) is employed. The train size and type of membrane employed is tailored based on the feed water quality. An antiscalant (approximately10 mg/L) is added to the concentrate stream to stabilize the silica and to prevent scale formation in the next high-pressure RO stage. The second RO stage consists of high-pressure or seawater RO membranes that can achieve 80% water recovery. The RO permeate is combined with the low-pressure RO permeate for discharge or beneficial use. The concentrate, approximately 2–3% of the initial feed volume, is either disposed of as a waste, or can be treated for zero liquid discharge (ZLD). Because many produced waters contain high levels of sodium and low levels of divalent ions, the SAR may be too high, even after treatment, for beneficial use of the water. In these cases, a limestone bed is used to add calcium to the water and lower the SAR. The following cost estimates were presented based on the pilot testing experience in the Powder River basin: $0.14 per bbl or $3.33 per 1,000 gal (not including energy or brine disposal); $0.08 per bbl or $1.90 per 1,000 gal for brine disposal. Cost estimates were not provided for the pilot test on tight sands produced water. 90PDF Image | Oil and Gas Produced Water Management

PDF Search Title:

Oil and Gas Produced Water ManagementOriginal File Name Searched:

report157.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |