PDF Publication Title:

Text from PDF Page: 003

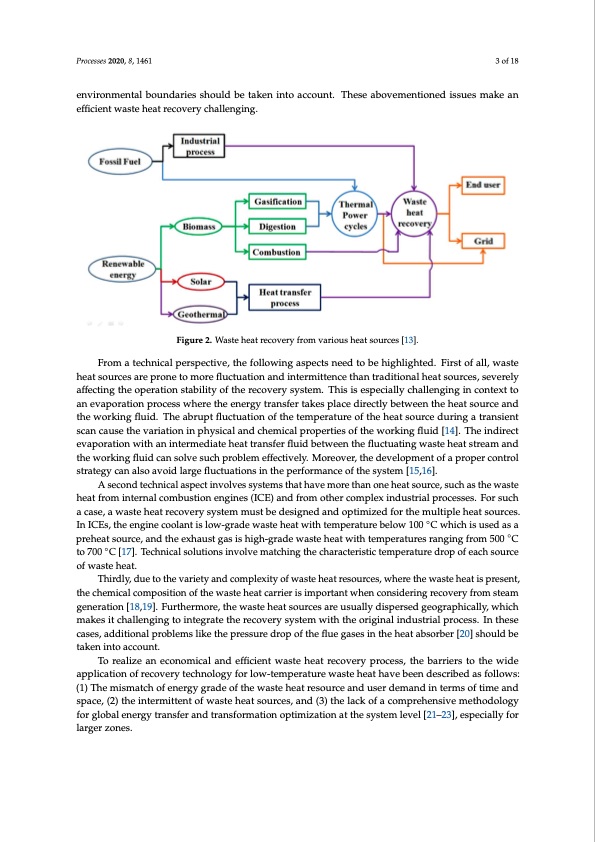

Processes 2020, 8, 1461 3 of 18 environmental boundaries should be taken into account. These abovementioned issues make an Processes 2020, 8, x FOR PEER REVIEW 3 of 18 efficient waste heat recovery challenging. Figure 2. Waste heat recovery from various heat sources [13]. Figure 2. Waste heat recovery from various heat sources [13]. From a technical perspective, the following aspects need to be highlighted. First of all, waste From a technical perspective, the following aspects need to be highlighted. First of all, waste heat sources are prone to more fluctuation and intermittence than traditional heat sources, severely heat sources are prone to more fluctuation and intermittence than traditional heat sources, severely affecting the operation stability of the recovery system. This is especially challenging in context to affecting the operation stability of the recovery system. This is especially challenging in context to an an evaporation process where the energy transfer takes place directly between the heat source and evaporation process where the energy transfer takes place directly between the heat source and the the working fluid. The abrupt fluctuation of the temperature of the heat source during a transient working fluid. The abrupt fluctuation of the temperature of the heat source during a transient scan scan cause the variation in physical and chemical properties of the working fluid [14]. The indirect cause the variation in physical and chemical properties of the working fluid [14]. The indirect evaporation with an intermediate heat transfer fluid between the fluctuating waste heat stream and evaporation with an intermediate heat transfer fluid between the fluctuating waste heat stream and the working fluid can solve such problem effectively. Moreover, the development of a proper control the working fluid can solve such problem effectively. Moreover, the development of a proper control strategy can also avoid large fluctuations in the performance of the system [15,16]. strategy can also avoid large fluctuations in the performance of the system [15,16]. A second technical aspect involves systems that have more than one heat source, such as the waste A second technical aspect involves systems that have more than one heat source, such as the heat from internal combustion engines (ICE) and from other complex industrial processes. For such waste heat from internal combustion engines(ICE) and from other complex industrial processes. For a case, a waste heat recovery system must be designed and optimized for the multiple heat sources. such a case, a waste heat recovery system must be designed and optimized for the multiple heat In ICEs, the engine coolant is low-grade waste heat with temperature below 100 ◦C which is used as a sources. In ICEs, the engine coolant is low-grade waste heat with temperature below 100 °C which is preheat source, and the exhaust gas is high-grade waste heat with temperatures ranging from 500 ◦C used as a preheat source, and the exhaust gas is high-grade waste heat with temperatures ranging to 700 ◦C [17]. Technical solutions involve matching the characteristic temperature drop of each source from 500 °C to 700 °C [17]. Technical solutions involve matching the characteristic temperature drop of waste heat. of each source of waste heat. Thirdly, due to the variety and complexity of waste heat resources, where the waste heat is present, Thirdly, due to the variety and complexity of waste heat resources, where the waste heat is the chemical composition of the waste heat carrier is important when considering recovery from steam present, the chemical composition of the waste heat carrier is important when considering recovery generation [18,19]. Furthermore, the waste heat sources are usually dispersed geographically, which from steam generation [18,19]. Furthermore, the waste heat sources are usually dispersed makes it challenging to integrate the recovery system with the original industrial process. In these geographically, which makes it challenging to integrate the recovery system with the original cases, additional problems like the pressure drop of the flue gases in the heat absorber [20] should be industrial process. In these cases, additional problems like the pressure drop of the flue gases in the taken into account. heat absorber [20] should be taken into account. To realize an economical and efficient waste heat recovery process, the barriers to the wide To realize an economical and efficient waste heat recovery process, the barriers to the wide application of recovery technology for low-temperature waste heat have been described as follows: application of recovery technology for low-temperature waste heat have been described as follows: (1) The mismatch of energy grade of the waste heat resource and user demand in terms of time and (1) The mismatch of energy grade of the waste heat resource and user demand in terms of time and space, (2) the intermittent of waste heat sources, and (3) the lack of a comprehensive methodology space, (2) the intermittent of waste heat sources, and (3) the lack of a comprehensive methodology for global energy transfer and transformation optimization at the system level [21–23], especially for for global energy transfer and transformation optimization at the system level [21–23], especially for larger zones. larger zones. 3. State-of-the-Art Thermodynamic Cycles for Waste Heat Recovery Various implementation pathways can be adopted with respect to the quality of waste heat sources [2]. The main approach is to utilize the available waste heat as heat source to drive the thermodynamic cycle and convert the thermal energy into useful power. One of the most important indicators for choosing a proper cycle is the operation temperature. Figure 3 depicts the possiblePDF Image | s-CO2) Power Cycle for Waste Heat Recovery

PDF Search Title:

s-CO2) Power Cycle for Waste Heat RecoveryOriginal File Name Searched:

processes-08-01461.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |