PDF Publication Title:

Text from PDF Page: 004

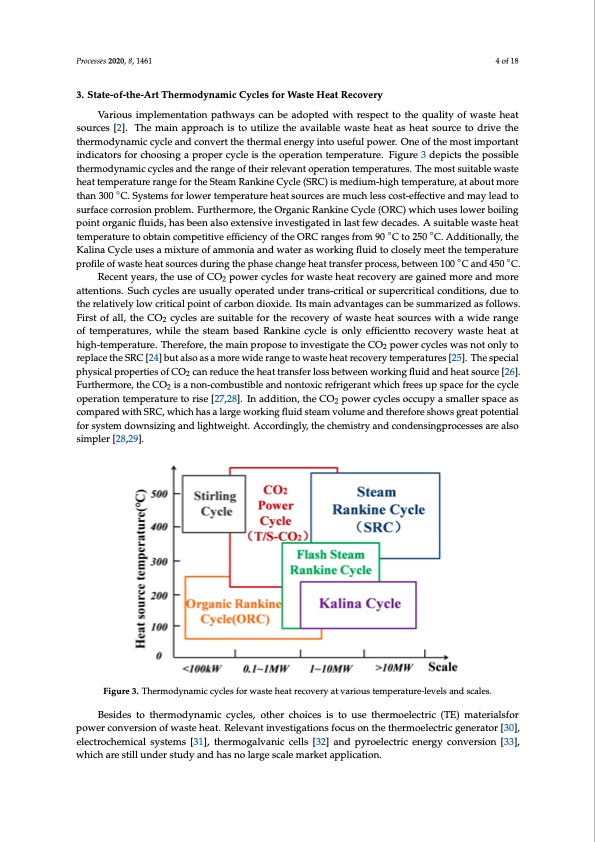

Processes 2020, 8, 1461 4 of 18 3. State-of-the-Art Thermodynamic Cycles for Waste Heat Recovery Various implementation pathways can be adopted with respect to the quality of waste heat sources [2]. The main approach is to utilize the available waste heat as heat source to drive the Processes 2020, 8, x FOR PEER REVIEW 4 of 18 thermodynamic cycle and convert the thermal energy into useful power. One of the most important indicators for choosing a proper cycle is the operation temperature. Figure 3 depicts the possible thermodynamic cycles and the range of their relevant operation temperatures. The most suitable thermodynamic cycles and the range of their relevant operation temperatures. The most suitable waste waste heat temperature range for the Steam Rankine Cycle(SRC) is medium-high temperature, at heat temperature range for the Steam Rankine Cycle (SRC) is medium-high temperature, at about more about more than 300 °C. Systems for lower temperature heat sources are much less cost-effective and than 300 ◦C. Systems for lower temperature heat sources are much less cost-effective and may lead to may lead to surface corrosion problem. Furthermore, the Organic Rankine Cycle(ORC) which uses surface corrosion problem. Furthermore, the Organic Rankine Cycle (ORC) which uses lower boiling lower boiling point organic fluids, has been also extensive investigated in last few decades. A suitable point organic fluids, has been also extensive investigated in last few decades. A suitable waste heat waste heat temperature to obtain competitive efficiency of the ORC ranges from 90 °C to 250 °C. temperature to obtain competitive efficiency of the ORC ranges from 90 ◦C to 250 ◦C. Additionally, the Additionally, the Kalina Cycle uses a mixture of ammonia and water as working fluid to closely meet Kalina Cycle uses a mixture of ammonia and water as working fluid to closely meet the temperature the temperature profile of waste heat sources during the phase change heat transfer process, between profile of waste heat sources during the phase change heat transfer process, between 100 ◦C and 450 ◦C. 100 °C and 450 °C. Recent years, the use of CO2 power cycles for waste heat recovery are gained more and more Recent years, the use of CO2 power cycles for waste heat recovery are gained more and more attentions. Such cycles are usually operated under trans-critical or supercritical conditions, due to attentions. Such cycles are usually operated under trans-critical or supercritical conditions,due to the the relatively low critical point of carbon dioxide. Its main advantages can be summarized as follows. relatively low critical point of carbon dioxide. Its main advantages can be summarized as follows. First of all, the CO2 cycles are suitable for the recovery of waste heat sources with a wide range First of all, the CO2 cycles are suitable for the recovery of waste heat sources with a wide range of of temperatures, while the steam based Rankine cycle is only efficientto recovery waste heat at temperatures, while the steam based Rankine cycle is only efficientto recovery waste heat at high- high-temperature. Therefore, the main propose to investigate the CO2 power cycles was not only to temperature. Therefore, the main propose to investigate the CO2 power cycles was not only to replace replace the SRC [24] but also as a more wide range to waste heat recovery temperatures [25]. The special the SRC [24] but also as a more wide range to waste heat recovery temperatures [25]. The special physical properties of CO2 can reduce the heat transfer loss between working fluid and heat source [26]. physical properties of CO2 can reduce the heat transfer loss between working fluid and heat source Furthermore, the CO2 is a non-combustible and nontoxic refrigerant which frees up space for the cycle [26]. Furthermore, the CO2 is a non-combustible and nontoxic refrigerant which frees up space for operation temperature to rise [27,28]. In addition, the CO2 power cycles occupy a smaller space as the cycle operation temperature to rise [27,28]. In addition, the CO2 power cycles occupy a smaller compared with SRC, which has a large working fluid steam volume and therefore shows great potential space as compared with SRC, which has a large working fluid steam volume and therefore shows for system downsizing and lightweight. Accordingly, the chemistry and condensingprocesses are also great potential for system downsizing and lightweight. Accordingly, the chemistry and simpler [28,29]. condensingprocesses are also simpler [28,29]. Figure 3. Thermodynamic cycles for waste heat recovery at various temperature-levels and scales. Figure 3. Thermodynamic cycles for waste heat recovery at various temperature-levels and scales. Besides to thermodynamic cycles, other choices is to use thermoelectric (TE) materialsfor Besides to thermodynamic cycles, other choices is to use thermoelectric (TE) materialsfor power power conversion of waste heat. Relevant investigations focus on the thermoelectric generator [30], conversion of waste heat. Relevant investigations focus on the thermoelectric generator [30], electrochemical systems [31], thermogalvanic cells [32] and pyroelectric energy conversion [33], electrochemical systems [31], thermogalvanic cells [32] and pyroelectric energy conversion [33], which are still under study and has no large scale market application. which are still under study and has no large scale market application. In summary, with respect to conventional thermodynamic cycles, supercritical carbon dioxide(s- CO2) cycles offer a wide range of operating temperatures and potentially higher efficiencies, and a much smaller environmental footprint [34–36]. Power cycles running on s-CO2 have received wide attention, and the number of publications has risen exponentially in recent years. However, the great potential for this technology in waste heat recovery remains to be further explored, which makes this comprehensive review of recent advances in s-CO2 cycles for waste heat recovery highly relevant.PDF Image | s-CO2) Power Cycle for Waste Heat Recovery

PDF Search Title:

s-CO2) Power Cycle for Waste Heat RecoveryOriginal File Name Searched:

processes-08-01461.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |