PDF Publication Title:

Text from PDF Page: 005

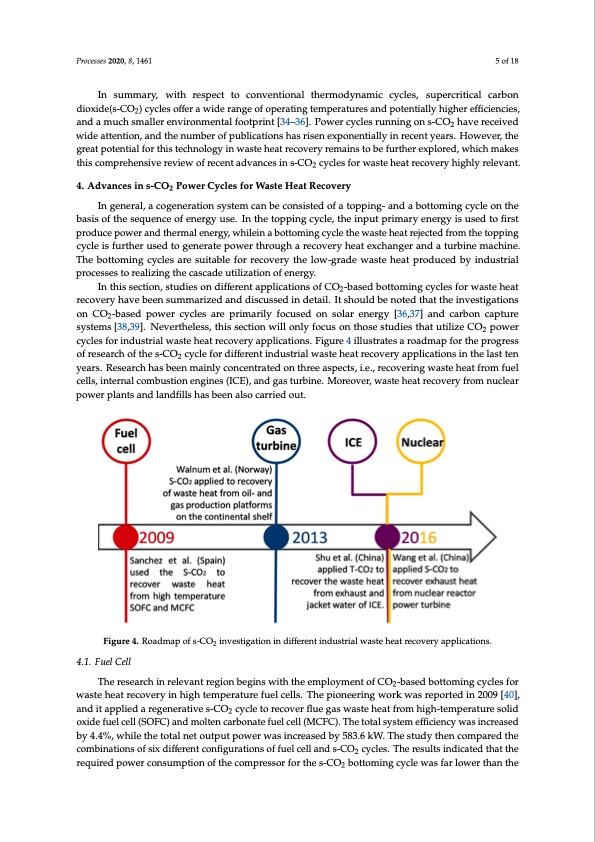

Processes 2020, 8, 1461 5 of 18 In summary, with respect to conventional thermodynamic cycles, supercritical carbon dioxide(s-CO2) cycles offer a wide range of operating temperatures and potentially higher efficiencies, and a much smaller environmental footprint [34–36]. Power cycles running on s-CO2 have received wide attention, and the number of publications has risen exponentially in recent years. However, the great potential for this technology in waste heat recovery remains to be further explored, which makes Processes 2020, 8, x FOR PEER REVIEW 5 of 18 this comprehensive review of recent advances in s-CO2 cycles for waste heat recovery highly relevant. 4. Advances in s-CO2Power Cycles for Waste Heat Recovery 4. Advances in s-CO2 Power Cycles for Waste Heat Recovery In general, a cogeneration system can be consisted of a topping- and a bottoming cycle on the In general, a cogeneration system can be consisted of a topping- and a bottoming cycle on the basis of the sequence of energy use. In the topping cycle, the input primary energy is used to first basis of the sequence of energy use. In the topping cycle, the input primary energy is used to first produce power and thermal energy, whilein a bottoming cycle the waste heat rejected from the produce power and thermal energy, whilein a bottoming cycle the waste heat rejected from the topping topping cycle is further used to generate power through a recovery heat exchanger and a turbine cycle is further used to generate power through a recovery heat exchanger and a turbine machine. machine. The bottoming cycles are suitable for recovery the low-grade waste heat produced by The bottoming cycles are suitable for recovery the low-grade waste heat produced by industrial industrial processes to realizing the cascade utilization of energy. processes to realizing the cascade utilization of energy. In this section, studies on different applications of CO2-based bottoming cycles for waste heat In this section, studies on different applications of CO2-based bottoming cycles for waste heat recovery have been summarized and discussed in detail. It should be noted that the investigations recovery have been summarized and discussed in detail. It should be noted that the investigations on CO2-based power cycles are primarily focused on solar energy [36,37] and carbon capture systems on CO2-based power cycles are primarily focused on solar energy [36,37] and carbon capture [38,39]. Nevertheless, this section will only focus on those studies that utilize CO2 power cycles for systems [38,39]. Nevertheless, this section will only focus on those studies that utilize CO2 power industrial waste heat recovery applications. Figure 4 illustrates a roadmap for the progress of research cycles for industrial waste heat recovery applications. Figure 4 illustrates a roadmap for the progress of the s-CO2 cycle for different industrial waste heat recovery applications in the last ten years. of research of the s-CO2 cycle for different industrial waste heat recovery applications in the last ten Research has been mainly concentrated on three aspects, i.e., recovering waste heat from fuel cells, years. Research has been mainly concentrated on three aspects, i.e., recovering waste heat from fuel internal combustion engines(ICE), and gas turbine. Moreover, waste heat recovery from nuclear cells, internal combustion engines (ICE), and gas turbine. Moreover, waste heat recovery from nuclear power plants and landfills has been also carried out. power plants and landfills has been also carried out. Figure 4. Roadmap of s-CO2 investigation in different industrial waste heat recovery applications. Figure 4. Roadmap of s-CO2 investigation in different industrial waste heat recovery applications. 4.1. Fuel Cell anditappliedaregeneratives-CO cycletorecoverfluegaswasteheatfromhigh-temperaturesolid waste heat recovery in high tempe2rature fuel cells. The pioneering work was reported in 2009 [40], oxide fuel cell (SOFC) and molten carbonate fuel cell (MCFC). The total system efficiency was increased and it applied a regenerative s-CO2 cycle to recover flue gas waste heat from high-temperature solid 4.1. Fuel Cell The research in relevant region begins with the employment of CO2-based bottoming cycles for waste heat recovery in high temperature fuel cells. The pioneering work was reported in 2009 [40], The research in relevant region begins with the employment of CO2-based bottoming cycles for by 4.4%, while the total net output power was increased by 583.6 kW. The study then compared the oxide fuel cell(SOFC) and molten carbonate fuel cell(MCFC). The total system efficiency was combinationsofsixdifferentconfigurationsoffuelcellands-CO cycles.Theresultsindicatedthatthe increased by 4.4%, while the total net output power was inc2reased by 583.6kW. The study then requiredpowerconsumptionofthecompressorforthes-CO bottomingcyclewasfarlowerthanthe compared the combinations of six different configurations o2f fuel cell and s-CO2 cycles. The results indicated that the required power consumption of the compressor for the s-CO2 bottoming cycle was far lower than the air bottoming cycle, and the operation performance of the bottoming cycle was less affected by the fuel cell operating temperature [41]. Bae et al. [42] compared to the thermodynamic performance of four different configurations of the s-CO2 bottoming cycle to recover waste heat from the MCFC flue gas and compared it with the regenerative air Rankine cycle. The results showed that the total efficiency of the system could be improved by nearly 11% by using the cascade cycle, whichPDF Image | s-CO2) Power Cycle for Waste Heat Recovery

PDF Search Title:

s-CO2) Power Cycle for Waste Heat RecoveryOriginal File Name Searched:

processes-08-01461.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |