PDF Publication Title:

Text from PDF Page: 012

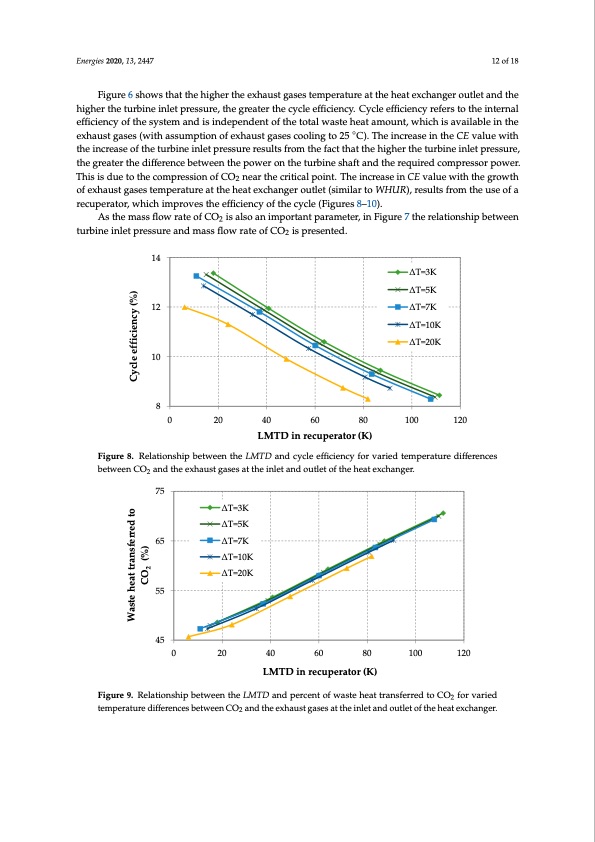

Energies 2020, 13, x FOR PEER REVIEW 13 of 18 Calculations of the energy efficiency indicators were carried out for different LMTD values, for a constant turbine inlet pressure of 22.5 MPa. In addition, the same calculations were repeated for varied temperature differences between CO2 and the exhaust gases at the inlet and outlet of the heat Energies 2020, 13, 2447 12 of 18 exchanger, ranging from 3 to 20 K. The relationship between the LMTD and cycle efficiency is presented in Figure 8. Figure 6 shows that the higher the exhaust gases temperature at the heat exchanger outlet and the higher the turbine inlet pressure, the greater the cycle efficiency. Cycle efficiency refers to the internal 14 efficiency of the system and is independent of the total waste heat amount, which is available in the C). The increase in the CE value with ΔT=5K 13 of 18 the increase of the turbine inlet pressure results from the fact that the higher the turbine inlet pressure, exhaust gases (with assumption of exhaust gases cooling to 25 Energies 2020, 13, x FOR PEER REVIEW the greater the diff1e2rence between the power on the turbine shaft and the requΔiTre=d7Kcompressor power. Calculations of the energy efficiency indicators were carried out for different LMTD values, for This is due to the compression of CO2 near the critical point. The increase in CE value with the growth a constant turbine inlet pressure of 22.5 MPa. In addition, the same calculaΔtiTo=n1s0Kwere repeated for of exhaust gases temperature at the heat exchanger outlet (similar to WHUR), results from the use of a varied temperature differences between CO2 and the exhaust gases at the inlet and outlet of the heat recuperator, which improves the efficiency of the cycle (Figures 8–10). exchanger, ranging from 3 to 20 K. The relationship between the LMTD and cycle efficiency is As the mass flow rate of CO2 is also an important parameter, in Figure 7 the relationship between presented in Figure 8. turbine inlet pressure and mass flow rate of CO2 is presented. 148 0 20 40 60 80 100 120 10 12 LMTD in recuperator (K) ΔT=5K ΔT=7K Figure 8. Relationship between the LMTD and cycle efficiency for varied temperature differences ΔT=10K between CO2 and the exhaust gases at the inlet and outlet of the heat exchanger. 10 of CO2 at the entry to and exit from the recuperator (between hot and cold side) is smaller. The smaller temperature difference between CO2 streams flowing countercurrent means that more heat of returning CO2 is8transferred to CO2 after compression. Otherwise, this energy would have to be “taken” from the system at the cooler so the energy would be “wasted”. The increase in CE with the 0 20 40 60 80 100 120 Figure 8 shows that the internal efficiency of the cycle increases if the difference in temperature decrease in the LMTD results from the fact that the smaller the LMTD, the more energy is transferred LMTD in recuperator (K) from the hot side of recuperator to the cold side of recuperator. By this way, more internal energy in the system is re-used and thus the efficiency of the cycle is increasing. The relationship between the Figure 8. Relationship between the LMTD and cycle efficiency for varied temperature differences Figure 8. Relationship between the LMTD and cycle efficiency for varied temperature differences LMTbDetwaenedn pCeOrceantdotfheweaxshtaeuhsteagtastersanatsftehreriendletoanCdOo2uitsleptroefstehnethedeaitnexFcihgaunrgee9r.. between CO2 and the exhaust gases at the inlet and outlet of the heat exchanger. 75 Figure 8 shows that the internal efficiency of the cycle increases if the difference in temperature 2 ΔT=3K of CO2 at the entry to and exit from the recuperator (between hot and cold side) is smaller. The smaller ΔT=5K temperature difference between CO2 streams flowing countercurrent means that more heat of “taken” from the system at the coΔoTl=e1r0sKo the energy would be “wasted”. The increase in CE with the decrease in the LMTD results from the fact that the smaller the LMTD, the more energy is transferred ΔT=20K from the hot side of recuperator to the cold side of recuperator. By this way, more internal energy in 55 the system is re-used and thus the efficiency of the cycle is increasing. The relationship between the LMTD and percent of waste heat transferred to CO2 is presented in Figure 9. 75 45 0 20 40 60 80 100 120 65 ΔT=7K returning CO2 is transferred to CO2 after compression. Otherwise, this energy would have to be 65 ΔT=3K ΔT=5K ΔT=7K LMTD in recuperator (K) Figure 9. Relationship between the LMTD and percent of waste heat transferred to CO2 for varied Figure 9. Relationship betweΔenT=t1h0eKLMTD and percent of waste heat transferred to CO2 for varied temperature differences between CO2 and the exhaust gases at the inlet and outlet of the heat exchanger. temperature differences between CO2 and the exhaust gases at the inlet and outlet of the heat exchanger. 55 45 0 20 40 60 80 100 120 LMTD in recuperator (K) ΔT=20K Figure 9. Relationship between the LMTD and percent of waste heat transferred to CO2 for varied ◦ ΔT=3K ΔT=20K ΔT=3K ΔT=20K Waste heat transferred to CO2 (%) Waste heat transferred to CO2 (%) Cycle efficiency (%) Cycle efficiency (%)PDF Image | Supercritical CO2-Brayton Cycle Nat Gas Compression Station

PDF Search Title:

Supercritical CO2-Brayton Cycle Nat Gas Compression StationOriginal File Name Searched:

energies-13-02447-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |