PDF Publication Title:

Text from PDF Page: 006

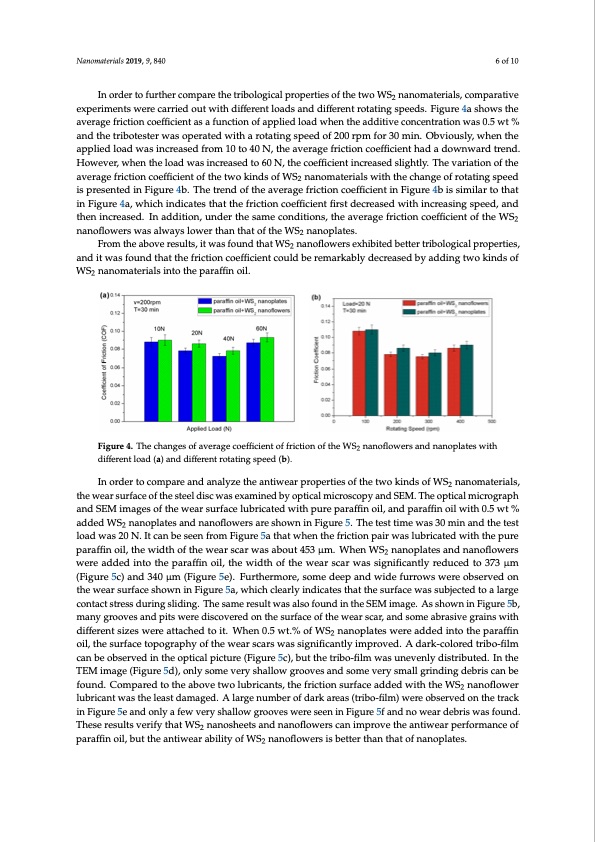

Nanomaterials 2019, 9, 8x4F0OR PEER REVIEW 66 of 10 In order to further compare the tribological properties of the two WS2 nanomaterials, InordertofurthercomparethetribologicalpropertiesofthetwoWS nanomaterials,comparative comparative experiments were carried out with different loads and diff2erent rotating speeds. Figure experiments were carried out with different loads and different rotating speeds. Figure 4a shows the 4a shows the average friction coefficient as a function of applied load when the additive average friction coefficient as a function of applied load when the additive concentration was 0.5 wt % concentration was 0.5 wt % and the tribotester was operated with a rotating speed of 200 rpm for 30 and the tribotester was operated with a rotating speed of 200 rpm for 30 min. Obviously, when the min. Obviously, when the applied load was increased from 10 to 40 N, the average friction applied load was increased from 10 to 40 N, the average friction coefficient had a downward trend. coefficient had a downward trend. However, when the load was increased to 60 N, the coefficient However, when the load was increased to 60 N, the coefficient increased slightly. The variation of the increased slightly. The variation of the average friction coefficient of the two kinds of WS2 averagefrictioncoefficientofthetwokindsofWS nanomaterialswiththechangeofrotatingspeed nanomaterials with the change of rotating speed i2s presented in Figure 4b. The trend of the average is presented in Figure 4b. The trend of the average friction coefficient in Figure 4b is similar to that friction coefficient in Figure 4b is similar to that in Figure 4a, which indicates that the friction in Figure 4a, which indicates that the friction coefficient first decreased with increasing speed, and coefficient first decreased with increasing speed, and then increased. In addition, under the same then increased. In addition, under the same conditions, the average friction coefficient of the WS conditions, the average friction coefficient of the WS2 nanoflowers was always lower than that of th2e nanoflowerswasalwayslowerthanthatoftheWS nanoplates. WS2 nanoplates. 2 Fromtheaboveresults,itwasfoundthatWS nanoflowersexhibitedbettertribologicalproperties, From the above results, it was found th2at WS2 nanoflowers exhibited better tribological and it was found that the friction coefficient could be remarkably decreased by adding two kinds of properties, and it was found that the friction coefficient could be remarkably decreased by adding WS nanomaterialsintotheparaffinoil. two2 kinds of WS2 nanomaterials into the paraffin oil. F Fi ig gu ur re e 4 4.. T Th he e c ch ha an ng ge es s o of f a av ve er ra ag ge e c co oe effif f ic ci ie en nt t o of f ffrriic cttiio on n o off tth he e W WS S 2 n na an no oflf lo ow we er rs s a an nd d n na an no op pl la at te es s w wi it th h 2 difffferent lload ((a)) and diiffffeerreenttrroottaattininggssppeeedd((bb)). . InordertocompareandanalyzetheantiwearpropertiesofthetwokindsofWS nanomaterials, In order to compare and analyze the antiwear properties of the two kinds of WS2 nanomaterials, the wear surface of the steel disc was examined by optical microscopy and SEM. The optical micrograph the wear surface of the steel disc was examined by optical microscopy and SEM. The optical and SEM images of the wear surface lubricated with pure paraffin oil, and paraffin oil with 0.5 wt % micrograph and SEM images of the wear surface lubricated with pure paraffin oil, and paraffin oil addedWS nanoplatesandnanoflowersareshowninFigure5.Thetesttimewas30minandthetest with 0.5 w2t % added WS2 nanoplates and nanoflowers are shown in Figure 5. The test time was 30 load was 20 N. It can be seen from Figure 5a that when the friction pair was lubricated with the pure min and the test load was 20 N. It can be seen from Figure 5a that when the friction pair was paraffinoil,thewidthofthewearscarwasabout453μm.WhenWS nanoplatesandnanoflowers lubricated with the pure paraffin oil, the width of the wear scar w2as about 453 μm. When WS2 were added into the paraffin oil, the width of the wear scar was significantly reduced to 373 μm nanoplates and nanoflowers were added into the paraffin oil, the width of the wear scar was (Figure 5c) and 340 μm (Figure 5e). Furthermore, some deep and wide furrows were observed on significantly reduced to 373 μm (Figure 5c) and 340 μm (Figure 5e). Furthermore, some deep and the wear surface shown in Figure 5a, which clearly indicates that the surface was subjected to a large wide furrows were observed on the wear surface shown in Figure 5a, which clearly indicates that the contact stress during sliding. The same result was also found in the SEM image. As shown in Figure 5b, surface was subjected to a large contact stress during sliding. The same result was also found in the many grooves and pits were discovered on the surface of the wear scar, and some abrasive grains with SEM image. As shown in Figure 5b, many grooves and pits were discovered on the surface of the different sizes were attached to it. When 0.5 wt.% of WS nanoplates were added into the paraffin wear scar, and some abrasive grains with different sizes w2 ere attached to it. When 0.5 wt.% of WS2 oil, the surface topography of the wear scars was significantly improved. A dark-colored tribo-film nanoplates were added into the paraffin oil, the surface topography of the wear scars was can be observed in the optical picture (Figure 5c), but the tribo-film was unevenly distributed. In the significantly improved. A dark-colored tribo-film can be observed in the optical picture (Figure 5c), TEM image (Figure 5d), only some very shallow grooves and some very small grinding debris can be but the tribo-film was unevenly distributed. In the TEM image (Figure 5d), only some very shallow found.Comparedtotheabovetwolubricants,thefrictionsurfaceaddedwiththeWS nanoflower grooves and some very small grinding debris can be found. Compared to the above tw2o lubricants, lubricant was the least damaged. A large number of dark areas (tribo-film) were observed on the track the friction surface added with the WS2 nanoflower lubricant was the least damaged. A large in Figure 5e and only a few very shallow grooves were seen in Figure 5f and no wear debris was found. number of dark areas (tribo-film) were observed on the track in Figure 5e and only a few very TheseresultsverifythatWS nanosheetsandnanoflowerscanimprovetheantiwearperformanceof shallow grooves were seen i2n Figure 5f and no wear debris was found. These results verify that WS2 paraffinoil,buttheantiwearabilityofWS nanoflowersisbetterthanthatofnanoplates. nanosheets and nanoflowers can improve2the antiwear performance of paraffin oil, but the antiwear ability of WS2 nanoflowers is better than that of nanoplates.PDF Image | Tribological Properties of WS2 Hexagonal Nanoplates Nanoflowers

PDF Search Title:

Tribological Properties of WS2 Hexagonal Nanoplates NanoflowersOriginal File Name Searched:

nanomaterials-09-00840.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |