PDF Publication Title:

Text from PDF Page: 003

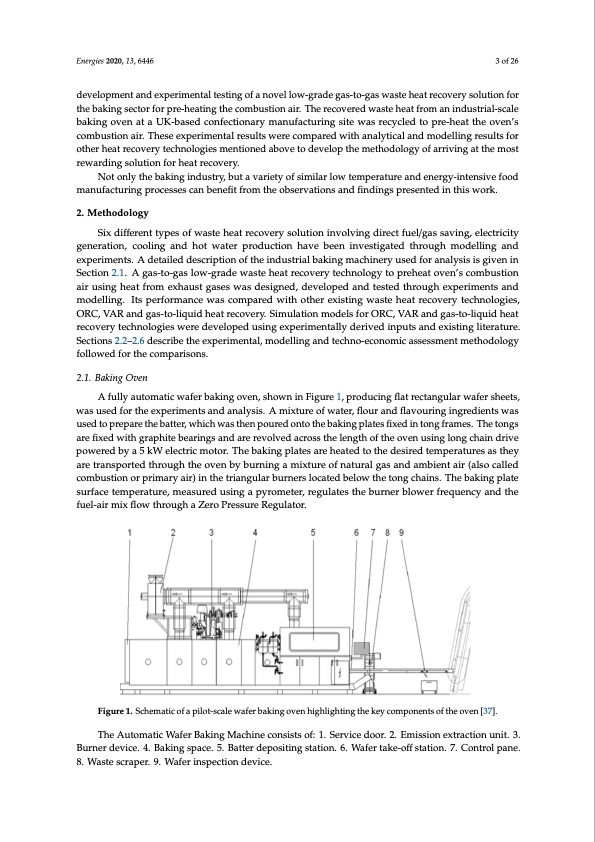

Energies 2020, 13, 6446 3 of 26 development and experimental testing of a novel low-grade gas-to-gas waste heat recovery solution for Energies 2020, 13, x FOR PEER REVIEW 3 of 26 the baking sector for pre-heating the combustion air. The recovered waste heat from an industrial-scale baking oven at a UK-based confectionary manufacturing site was recycled to pre-heat the oven’s to pre-heat the oven’s combustion air. These experimental results were compared with analytical and combustion air. These experimental results were compared with analytical and modelling results for modelling results for other heat recovery technologies mentioned above to develop the methodology other heat recovery technologies mentioned above to develop the methodology of arriving at the most of arriving at the most rewarding solution for heat recovery. rewarding solution for heat recovery. Not only the baking industry, but a variety of similar low temperature and energy-intensive Not only the baking industry, but a variety of similar low temperature and energy-intensive food food manufacturing processes can benefit from the observations and findings presented in this work. manufacturing processes can benefit from the observations and findings presented in this work. 2. Methodology 2. Methodology Six different types of waste heat recovery solution involving direct fuel/gas saving, electricity Six different types of waste heat recovery solution involving direct fuel/gas saving, electricity generation, cooling and hot water production have been investigated through modelling and generation, cooling and hot water production have been investigated through modelling and experiments. A detailed description of the industrial baking machinery used for analysis is given in experiments. A detailed description of the industrial baking machinery used for analysis is given in Section 2.1. A gas-to-gas low-grade waste heat recovery technology to preheat oven’s combustion air Section 2.1. A gas-to-gas low-grade waste heat recovery technology to preheat oven’s combustion using heat from exhaust gases was designed, developed and tested through experiments and air using heat from exhaust gases was designed, developed and tested through experiments and modelling. Its performance was compared with other existing waste heat recovery technologies, modelling. Its performance was compared with other existing waste heat recovery technologies, ORC, VAR and gas-to-liquid heat recovery. Simulation models for ORC, VAR and gas-to-liquid heat ORC, VAR and gas-to-liquid heat recovery. Simulation models for ORC, VAR and gas-to-liquid heat recovery technologies were developed using experimentally derived inputs and existing literature. recovery technologies were developed using experimentally derived inputs and existing literature. Sections 2.2–2.6 describe the experimental, modelling and techno-economic assessment methodology Sections 2.2–2.6 describe the experimental, modelling and techno-economic assessment methodology followed for the comparisons. followed for the comparisons. 2.1. Baking Oven A fully automatic wafer baking oven, shown in Figure 1, producing ffllat rectangular wafer sheets, was used for the experiments and analysis. A mixture of water, flflour and ffllavouring ingredients was usedttopprreeppaarereththeebabtatettre,rw,hwichhicwhawsathsetnhepnouproeudroendtonthtoebthaekibnagkpinlagtepslfiaxtesdfinxetodnignftroanmgesfr.aTmhest.oTnhges atorengfisxeadrewfiixtehdgwraipthigterabpehairtienbgesaarnindgasraenrdevaorlevreedvaoclvroesdsatchreolsesntghtehleonf gththe ofvtehneuosvineng ulosninggclhoaning cdhraivine pdoriwverpeodwbeyread5bkyWa e5lkecWtrieclemctortiocrm. Tohtoerb. Takhienbgapkliantgespalaretehseaarteehdetaotethdetodethsiereddestiermedpteermatpuererastausrethseays athreytrarnesptroarntesdpotrhtreodutghrothueghovthene boyvebnubrnyinbguranminigxtaurmeioxftunraetuorfanl agtausralngdaasmanbidenatmabirie(natlsaoirca(alllesdo coamllebducsotimonbuosrtpiornimoarrpyriamira)riny athire)tirniathnegutrliarnbgurlnarerbsulronceartsedlobcealtoewd btehleowtonthgecthoaningsc.hTahinesb.aTkhienbgapkliantge spularfteacseutrefamcepeteramtupreer,amtuerea,sumreadsurseindguasinpgyraompyertoemr,eretegru,lraetgeusltahtesbtuhrenbeurrbnleorwbelrowfrerqufrenqcuyenancydatnhde ftuhelf-uaierl-mairxmfloixwfltohwrotuhgrhouagZhearoZPereosPsurersesRuereguRleagtourl.ator. Figure 1. Schematic of a pilot-scale wafer baking oven highlighting the key components of the oven [37]. Figure 1. Schematic of a pilot-scale wafer baking oven highlighting the key components of the oven [37]. The Automatic Wafer Baking Machine consists of: 1. Service door. 2. Emission extraction unit. 3. Burner device. 4. Baking space. 5. Batter depositing station. 6. Wafer take-off station. 7. Control pane. The Automatic Wafer Baking Machine consists of: 1. Service door. 2. Emission extraction unit. 3. Burner device. 4. Baking space. 5. Batter depositing station. 6. Wafer take-off station. 7. Control pane. 8. Waste scraper. 9. Wafer inspection device. The batter is baked into wafer sheets in one revolution. These wafer sheets are carefully collected in the wafer sheet take-off station and sent to the processing line. The oven is also supplied with a cooling or secondary air flow through the sidewalls to protect the bearings from any damage 8. Waste scraper. 9. Wafer inspection device.PDF Image | Waste Heat Recovery Technologies for the Food Processing Industry

PDF Search Title:

Waste Heat Recovery Technologies for the Food Processing IndustryOriginal File Name Searched:

energies-13-06446.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |