PDF Publication Title:

Text from PDF Page: 004

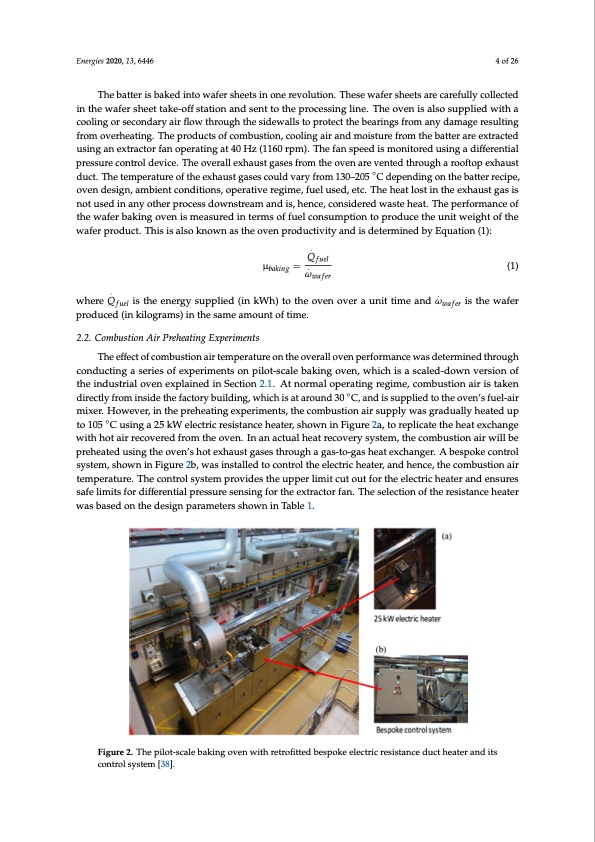

Energies 2020, 13, 6446 4 of 26 The batter is baked into wafer sheets in one revolution. These wafer sheets are carefully collected in the wafer sheet take-off station and sent to the processing line. The oven is also supplied with a cooling or secondary air flow through the sidewalls to protect the bearings from any damage resulting from overheating. The products of combustion, cooling air and moisture from the batter are extracted using an extractor fan operating at 40 Hz (1160 rpm). The fan speed is monitored using a differential pressure control device. The overall exhaust gases from the oven are vented through a rooftop exhaust Energies 2020, 13, x FOR PEER REVIEW ◦ 4 of 26 duct.Thetemperatureoftheexhaustgasescouldvaryfrom130–205 Cdependingonthebatterrecipe, oven design, ambient conditions, operative regime, fuel used, etc. The heat lost in the exhaust gas is resulting from overheating. The products of combustion, cooling air and moisture from the batter are not used in any other process downstream and is, hence, considered waste heat. The performance of extracted using an extractor fan operating at 40 Hz (1160 rpm). The fan speed is monitored using a thewafedriffbeareknitniagloprveessnuirsemconetarsoulrdedvicine.tTehremosveorfalflueexlhacuosntsguamsespftriomnthoeporvoednuacrevtheneteudntihtrwouegihghatofthe rooftop exhaust duct. The temperature of the exhaust gases could vary from 130–205 °C depending wafer product. This is also known as the oven productivity and is determined by Equation (1): on the batter recipe, oven design, ambient conditions, operative regime, fuel used, etc. The heat lost . in the exhaust gas is not used in any other process downstream and is, hence, considered waste heat. The performance of the wafer baking oven is measured in terms of fuel consumption to produce the Qfuel μbaking = . (1) unit weight of the wafer product. This is also knownωawsatfhere oven productivity and is determined by Equation (1): whereQ. istheenergysupplied(inkWh)totheovenoveraunittimeandω. isthewafer fuel μ = 𝑄 wafer (1) produced (in kilograms) in the same amount of time𝜔. where 𝑄 is the energy supplied (in kWh) to the oven over a unit time and 𝜔 is the wafer 2.2. Combustion Air Preheating Experiments produced (in kilograms) in the same amount of time. The effect of combustion air temperature on the overall oven performance was determined through 2.2. Combustion Air Preheating Experiments conducting a series of experiments on pilot-scale baking oven, which is a scaled-down version of The effect of combustion air temperature on the overall oven performance was determined the industrial oven explained in Section 2.1. At normal operating regime, combustion air is taken through conducting a series of experiments on pilot-scale ba◦king oven, which is a scaled-down directlyfrominsidethefactorybuilding,whichisataround30 C,andissuppliedtotheoven’sfuel-air version of the industrial oven explained in Section 2.1. At normal operating regime, combustion air mixer. However, in the preheating experiments, the combustion air supply was gradually heated up ◦ is taken directly from inside the factory building, which is at around 30 °C, and is supplied to the to 105 C using a 25 kW electric resistance heater, shown in Figure 2a, to replicate the heat exchange oven’s fuel-air mixer. However, in the preheating experiments, the combustion air supply was withhotgraidruraelclyohveartedufprotmo10th5e°Couvseing.aIn25aknWaeclteuctarlichresaitstraencoevheartyers,yshsotewmn,inthFeigcuorem2ab,utostrieopnlicaitrewillbe preheatethdeuhseiantgetxhcheaonvgenw’sithohtoetxahirauresctogvaerseds ftrhormoutgheh oavgena.s-Itno-agnaaschtuealtheexacthraecnogver.yAsybsetesmp,otkhe control combustion air will be preheated using the oven’s hot exhaust gases through a gas-to-gas heat system, shown in Figure 2b, was installed to control the electric heater, and hence, the combustion air exchanger. A bespoke control system, shown in Figure 2b, was installed to control the electric heater, temperature. The control system provides the upper limit cut out for the electric heater and ensures and hence, the combustion air temperature. The control system provides the upper limit cut out for safe limits for differential pressure sensing for the extractor fan. The selection of the resistance heater the electric heater and ensures safe limits for differential pressure sensing for the extractor fan. The was based on the design parameters shown in Table 1. selection of the resistance heater was based on the design parameters shown in Table 1. Figure 2. The pilot-scale baking oven with retrofitted bespoke electric resistance duct heater and its Figure 2. The pilot-scale baking oven with retrofitted bespoke electric resistance duct heater and its control system [38]. control system [38]. Table 1. Design parameters for a combustion air resistance heater.PDF Image | Waste Heat Recovery Technologies for the Food Processing Industry

PDF Search Title:

Waste Heat Recovery Technologies for the Food Processing IndustryOriginal File Name Searched:

energies-13-06446.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |