PDF Publication Title:

Text from PDF Page: 007

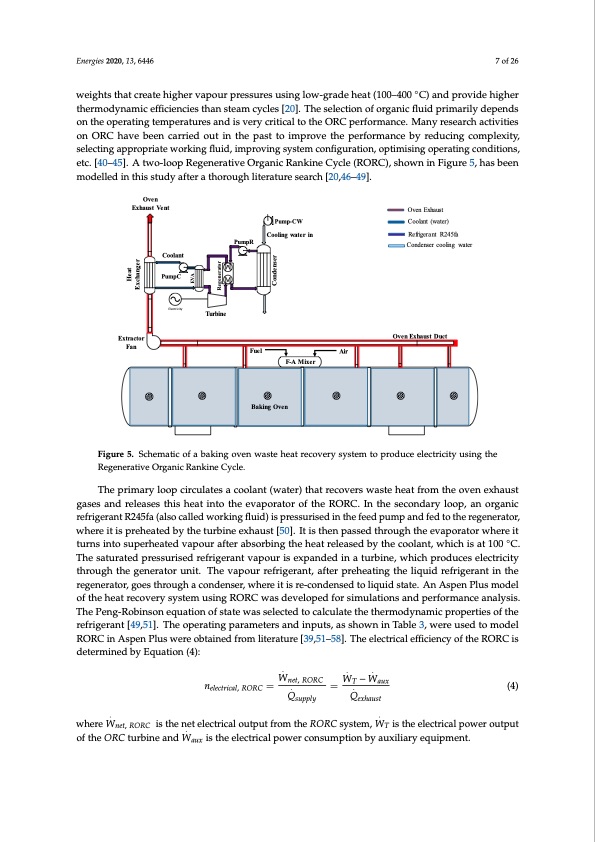

Energies 2020, 13, 6446 7 of 26 weights that create higher vapour pressures using low-grade heat (100–400 ◦C) and provide higher thermodynamic efficiencies than steam cycles [20]. The selection of organic fluid primarily depends on the operating temperatures and is very critical to the ORC performance. Many research activities on ORC have been carried out in the past to improve the performance by reducing complexity, selecting appropriate working fluid, improving system configuration, optimising operating conditions, etc. [40–45]. A two-loop Regenerative Organic Rankine Cycle (RORC), shown in Figure 5, has been Energies 2020, 13, x FOR PEER REVIEW modelled in this study after a thorough literature search [20,46–49]. 7 of 26 Ove n Exhaust Vent Coolant PumpC Electricity Pump-CW Cooling water in F-A Mixer Oven Exhaust Coolant (water) Refrigerant R245fa Condenser cooling water Oven Exhaust Duct PumpR Turbine Fue l Figure 5. Schematic of a baking oven waste heat recovery system to produce electricity using the Figure 5. Schematic of a baking oven waste heat recovery system to produce electricity using the Extractor Fan Air Baking Oven Regenerative Organic Rankine Cycle. Regenerative Organic Rankine Cycle. The primary loop circulates a coolant (water) that recovers waste heat from the oven exhaust The primary loop circulates a coolant (water) that recovers waste heat from the oven exhaust gases and releases this heat into the evaporator of the RORC. In the secondary loop, an organic gases and releases this heat into the evaporator of the RORC. In the secondary loop, an organic refrigerant R245fa (also called working fluid) is pressurised in the feed pump and fed to the refrigerant R245fa (also called working fluid) is pressurised in the feed pump and fed to the regenerator, regenerator, where it is preheated by the turbine exhaust [50]. It is then passed through the where it is preheated by the turbine exhaust [50]. It is then passed through the evaporator where it evaporator where it turns into superheated vapour after absorbing the heat released by the coolant,◦ turns into superheated vapour after absorbing the heat released by the coolant, which is at 100 C. which is at 100 °C. The saturated pressurised refrigerant vapour is expanded in a turbine, which The saturated pressurised refrigerant vapour is expanded in a turbine, which produces electricity produces electricity through the generator unit. The vapour refrigerant, after preheating the liquid through the generator unit. The vapour refrigerant, after preheating the liquid refrigerant in the refrigerant in the regenerator, goes through a condenser, where it is re-condensed to liquid state. An regenerator, goes through a condenser, where it is re-condensed to liquid state. An Aspen Plus model Aspen Plus model of the heat recovery system using RORC was developed for simulations and of the heat recovery system using RORC was developed for simulations and performance analysis. performance analysis. The Peng-Robinson equation of state was selected to calculate the The Peng-Robinson equation of state was selected to calculate the thermodynamic properties of the thermodynamic properties of the refrigerant [49,51]. The operating parameters and inputs, as shown refrigerant [49,51]. The operating parameters and inputs, as shown in Table 3, were used to model in Table 3, were used to model RORC in Aspen Plus were obtained from literature [39,51–58]. The RORC in Aspen Plus were obtained from literature [39,51–58]. The electrical efficiency of the RORC is electrical efficiency of the RORC is determined by Equation (4): determined by Equation (4): 𝑊 𝑊 −𝑊 ɳ = , = where 𝑊 n = Wnet, RORC = WT −Waux electrical, RORC . . , , . . . 𝑄 𝑄 (4) (4) is the net electrical output from the RORC system, 𝑊 is the electrical power Qsupply Qexhaust output of the ORC turbine and 𝑊 is the electrical power consumption by auxiliary equipment. .. The effectiveness of the heat recovery system involving RORC is determined by Equation (5): where Wnet, RORC is the net electrical output from the RORC system, WT is the electrical power output . 𝑄 of the ORC turbine and Waux is the electrical powerconsu,mption by auxiliary equipment. ƞ = 𝑄 (5) where 𝑄 , is the rate of gas used by a typical gas engine to produce same amount of electricity as produced by the RORC system using the recoverable oven waste heat 𝑄. Heat Exchange r EVA Regenerator CondenserPDF Image | Waste Heat Recovery Technologies for the Food Processing Industry

PDF Search Title:

Waste Heat Recovery Technologies for the Food Processing IndustryOriginal File Name Searched:

energies-13-06446.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |