PDF Publication Title:

Text from PDF Page: 010

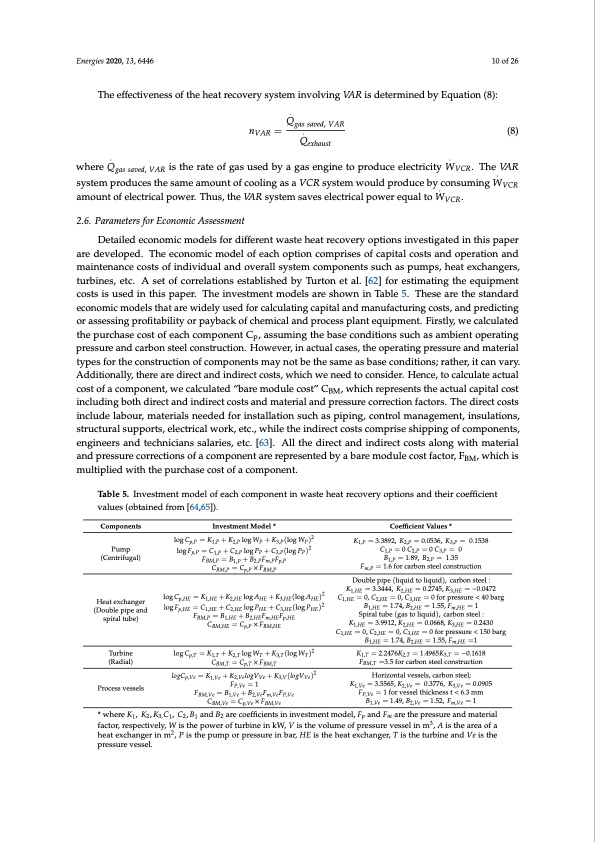

Energies 2020, 13, 6446 10 of 26 The effectiveness of the heat recovery system involving VAR is determined by Equation (8): . n = Qgas saved, VAR (8) VAR . Qexhaust .. where Qgas saved, VAR is the rate of gas used by a gas engine to produce electricity WVCR. The.VAR system produces the same amount of cooling as a VCR system would produce by.consuming WVCR amount of electrical power. Thus, the VAR system saves electrical power equal to WVCR. 2.6. Parameters for Economic Assessment Detailed economic models for different waste heat recovery options investigated in this paper are developed. The economic model of each option comprises of capital costs and operation and maintenance costs of individual and overall system components such as pumps, heat exchangers, turbines, etc. A set of correlations established by Turton et al. [62] for estimating the equipment costs is used in this paper. The investment models are shown in Table 5. These are the standard economic models that are widely used for calculating capital and manufacturing costs, and predicting or assessing profitability or payback of chemical and process plant equipment. Firstly, we calculated the purchase cost of each component Cp, assuming the base conditions such as ambient operating pressure and carbon steel construction. However, in actual cases, the operating pressure and material types for the construction of components may not be the same as base conditions; rather, it can vary. Additionally, there are direct and indirect costs, which we need to consider. Hence, to calculate actual cost of a component, we calculated “bare module cost” CBM, which represents the actual capital cost including both direct and indirect costs and material and pressure correction factors. The direct costs include labour, materials needed for installation such as piping, control management, insulations, structural supports, electrical work, etc., while the indirect costs comprise shipping of components, engineers and technicians salaries, etc. [63]. All the direct and indirect costs along with material and pressure corrections of a component are represented by a bare module cost factor, FBM, which is multiplied with the purchase cost of a component. Table 5. Investment model of each component in waste heat recovery options and their coefficient values (obtained from [64,65]). Components Pump (Centrifugal) Heat exchanger (Double pipe and spiral tube) Turbine (Radial) Process vessels Investment Model * log Cp,P = K1,P + K2,P log WP + K3,P (log WP )2 logFp,P =C1,P+C2,PlogPP+C3,P(logPP)2 FBM,P = B1,P + B2,PFm,PFp,P CBM,P = Cp,P × FBM,P Coefficient Values * K1,P = 3.3892, K2,P = 0.0536, K3,P = 0.1538 C1,P =0C2,P =0C3,P = 0 B1,P = 1.89, B2,P = 1.35 Fm,P = 1.6 for carbon steel construction Double pipe (liquid to liquid), carbon steel : K1,HE = 3.3444, K2,HE = 0.2745, K3,HE = −0.0472 C1,HE = 0, C2,HE = 0, C3,HE = 0 for pressure < 40 barg B1,HE = 1.74, B2,HE = 1.55, Fm,HE = 1 Spiral tube (gas to liquid), carbon steel : K1,HE = 3.9912, K2,HE = 0.0668, K3,HE = 0.2430 C1,HE = 0, C2,HE = 0, C3,HE = 0 for pressure < 150 barg B1,HE = 1.74, B2,HE = 1.55, Fm,HE =1 K1,T =2.2476K2,T =1.4965K3,T =−0.1618 FBM,T =3.5 for carbon steel construction Horizontal vessels, carbon steel; K1,Ve = 3.5565, K2,Ve = 0.3776, K3,Ve = 0.0905 FP,Ve = 1 for vessel thickness t < 6.3 mm B1,Ve = 1.49, B2,Ve = 1.52, Fm,Ve = 1 log Cp,HE = K1,HE + K2,HE log AHE + K3,HE (log AHE ) log Fp,HE = C1,HE + C2,HE log PHE + C3,HE (log PHE )2 FBM,P = B1,HE + B2,HEFm,HEFp,HE CBM,HE = Cp,P × FBM,HE logCp,T =K1,T+K2,TlogWT+K3,T(logWT)2 CBM,T = Cp,T × FBM,T logCp,Ve = K1,Ve + K2,VelogVVe + K3,V(logVVe)2 FP,Ve = 1 FBM,Ve = B1,Ve + B2,VeFm,VeFP,Ve CBM,Ve = Cp,Ve × FBM,Ve 2 * where K1 , K2 , K3, C1 , C2 , B1 and B2 are coefficients in investment model, Fp and Fm are the pressure and material factor, respectively, W is the power of turbine in kW, V is the volume of pressure vessel in m3, A is the area of a heat exchanger in m2, P is the pump or pressure in bar, HE is the heat exchanger, T is the turbine and Ve is the pressure vessel.PDF Image | Waste Heat Recovery Technologies for the Food Processing Industry

PDF Search Title:

Waste Heat Recovery Technologies for the Food Processing IndustryOriginal File Name Searched:

energies-13-06446.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |