PDF Publication Title:

Text from PDF Page: 009

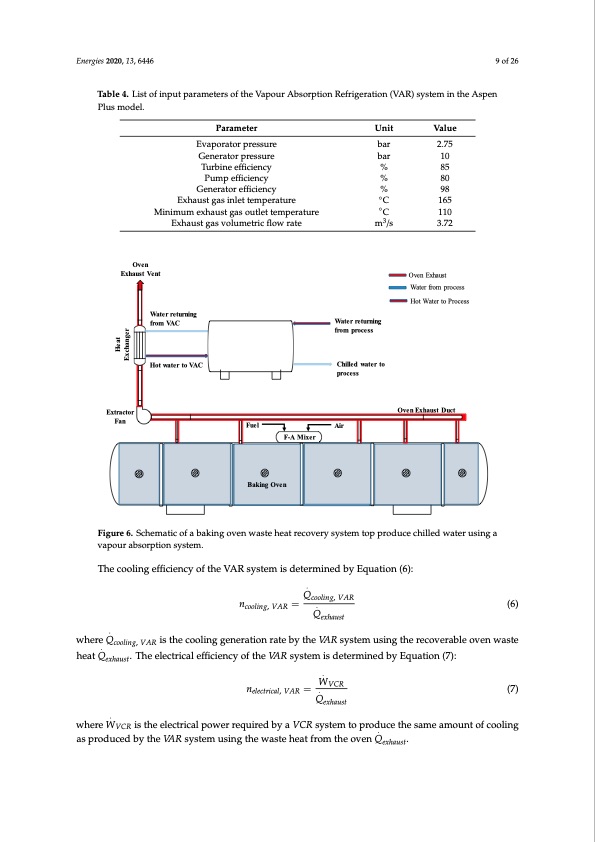

2.5. Vapour Absorption Refrigeration (VAR) System Model Pump efficiency % 80 A VAR system, shown in Figure 6, is a closed loop cycle that produces a refrigeration or cooling effect using heat as primary energy input instead of electrical power, which is used for driving a Energies 2020, 13, 6446 9 of 26 vapour compression cycle [22]. The evaporation, expansion and condensation stages in a VAR system are the same as the vapour compression refrigeration (VCR) system. However, an absorber, generator Table 4. List of input parameters of the Vapour Absorption Refrigeration (VAR) system in the Aspen and pump replace the compressor in a VCR system. A VAR model was developed in Aspen Plus Plus model. using a mixture of ammonia and water as the working fluid [59–61]. In the generator, the rich ammonia/water mixture is heated to desorb the refrigerant. Hot water produced by extracting the waste heat from the oven exhaust gases is used as a thermal energy input to the generator. The Parameter Unit Value Evaporator pressure bar 2.75 refrigerant vapour then enters the rectifier, where it is cooled by the ammonia-rich solution. This Generator pressure bar 10 preheats the ammonia-rich solution before it is sent to the generator. The refrigerant vapour flows to Turbine efficiency % 85 the water-cooled condenser, where it is completely liquefied. The liquefied refrigerant is further Pump efficiency % 80 cooled in a refrigerant heat exchanger and flows through the expansion valve. After pressure Generator efficiency % 98 ◦ reduction, the refrigerEaxnhtafluoswt gsatsointhletetevmapoeratoureunit, where heat fromCthe chilled w1a6t5er evaporates Minimum exhaust gas outlet temperature ◦C 110 the refrigerant. The refrigerant then moves to the absorber, where it mixes with the lean ammonia Exhaust gas volumetric flow rate m3/s 3.72 solution and forms a rich solution. This rich solution is then pumped back to the generator after some preheating in the rectifier. Oven Exhaust Vent Oven Exhaust Water from process Hot Water to Process Oven Exhaust Duct Water returning from VAC Hot water to VAC Water returning from process Chilled water to process Air Extractor Fan Fuel F-A Mixer Baking Oven Figure 6. Schematic of a baking oven waste heat recovery system top produce chilled water using a vapour absorption system. The cooling efficiency of the VAR system is determined by Equation (6): . n = Qcooling, VAR (6) cooling, VAR . Qexhaust . where Qcooling, VAR is the cooling generation rate by the VAR system using the recoverable oven waste . heat Qexhaust. The electrical efficiency of the VAR system is determined by Equation (7): . where WVCR is the electrical power required by a VCR system to produce the same amount of cooling . as produced by the VAR system using the waste heat from the oven Qexhaust. . n = WVCR (7) electrical, VAR . Qexhaust Heat Exchange rPDF Image | Waste Heat Recovery Technologies for the Food Processing Industry

PDF Search Title:

Waste Heat Recovery Technologies for the Food Processing IndustryOriginal File Name Searched:

energies-13-06446.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |