PDF Publication Title:

Text from PDF Page: 006

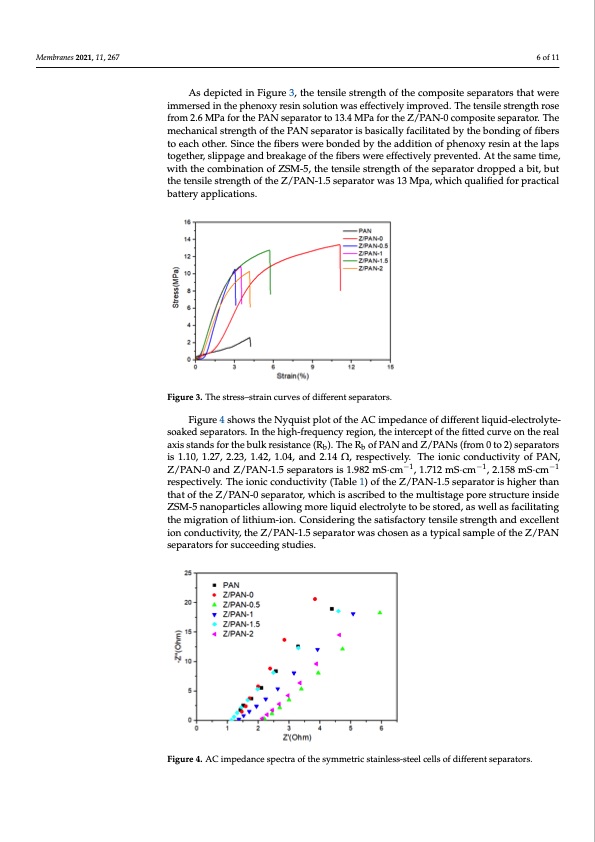

Membranes 2021, 11, x FOR PEER REVIEW Membranes 2021, 11, x FOR PEER REVIEW Membranes 2021, 11, 267 6 of 11 6 of 11 6 of 11 As depicted in Figure 3, the tensile strength of the composite separators that were As depicted in Figure 3, the tensile strength of the composite separators that were As depicted in Figure 3, the tensile strength of the composite separators that were immersed in the phenoxy resin solution was effectively improved. The tensile strength immersed in the phenoxy resin solution was effectively improved. The tensile strength immersed in the phenoxy resin solution was effectively improved. The tensile strength rose rose from 2.6 MPa for the PAN separator to 13.4 MPa for the Z/PAN-0 composite separa- rose from 2.6 MPa for the PAN separator to 13.4 MPa for the Z/PAN-0 composite separa- from 2.6 MPa for the PAN separator to 13.4 MPa for the Z/PAN-0 composite separator. The tor. The mechanical strength of the PAN separator is basically facilitated by the bonding mtoerc.hTahneicmalecshtraenigctahlsotfrethnegtPhAoNftsheepaPrAatNorsiespbaarasitcoarlliysbfacsiilcitaalltyedfabcyilitthaetebdobnyditnhgeobfofinbdeinrsg of fibers to each other. Since the fibers were bonded by the addition of phenoxy resin at tofefaibcehrsothoeer.acShinoctehtehr.eSfiinbecersthweefriebberosnwdedrebbyotnhdeeaddbdyititohne aodf dpihtieonnoxoyf prehseinoaxtythreslianpast the laps together, slippage and breakage of the fibers were effectively prevented. At the ttohgeeltahpesr,tsoligpepthagere,asnlidppbaregaekangdeobfrethaekafigberosfwtheerefiebfefersctwiverlyepefrfevcetinvteldy.pArtetvheensteadm.eAttimthee, same time, with the combination of ZSM-5, the tensile strength of the separator dropped wsaimthethtiemceo,mwbitihnathtieoncoomfbZiSnMat-io5,ntohfeZteSnMsi-l5e,sthtrentegntshiloefsthrensgetphaoraftohredseroppapraetdoradbriot,pbpuedt a bit, but the tensile strength of the Z/PAN-1.5 separator was 13 Mpa, which qualified for tahebite,nbsuiltethsteretenngstihleosfttrheengZt/hPoAfNth-e1.Z5/sPeApaNr-a1t.o5rswepaasr1a3toMrpwaa,sw1h3iMchpqau,awlihfiiecdhfqouraplirfaiecdticfaolr practical battery applications. bpartatcetriycalpbpaltitceartyioanpsp.lications. Figure 3. The stress–strain curves of different separators. Figure 3. The stress–strain curves of different separators. Figure 3. The stress–strain curves of different separators. Figure 4 shows the Nyquist plot of the AC impedance of different liquid-electrolyte- Figure 4 shows the Nyquist plot of the AC impedance of different liquid-electrolyte- Figure 4 shows the Nyquist plot of the AC impedance of different liquid-electrolyte- soaked separators. In the high-frequency region, the intercept of the fitted curve on the soaked separators. In the high-frequency region, the intercept of the fitted curve on the soaked separators. In the high-frequency region, the intercept of the fitted curve on the real real axis stands for the bulk resistance (Rb). The Rb of PAN and Z/PANs (from 0 to 2) sep- arxeiaslsatxainsdsstafonrdtshfeobruthlkerbeusilsktarnecsies(tRanc).eT(hReb)R.ThoefPRAbNofaPnAdNZ/aPnAdNZs/P(fAroNms0(frtom2)0setpoa2r)atsoerps- bb arators is 1.10, 1.27, 2.23, 1.42, 1.04, and 2.14 Ω, respectively. The ionic conductivity of iasra1t.1o0rs,1is.217.,120.,213.,271,.42.,231,.014.4,2a,n1d.024.,14anΩd,2r.e1s4pΩec,tirveeslpye.ctTivhelyio.nTihcecoionndicuctoivnidtyucotifvPitAyNo,f PAN, Z/PAN-0 and Z/PAN-1.5 separators is 1.982 mS·cm−1, 1.712 mS·cm−1, 2.158 mS·cm−1 −1 −1 −1−1 ZP/APNA,NZ-/0PAanNd-0Za/nPdAZN/-P1A.5Ns-e1p.5arsaetpoarsraitso1rs.9i8s21m.98S2·cmS·c,m1.7,12.7m12S·mcmS·cm, 2,.125.185m8 mS·Scm·cm respectively. The ionic conductivity (Table 1) of the Z/PAN-1.5 separator is higher than respectively.. The iioniic cconducttiivity ((Taablle11))ooffththeeZZ//PAN--1..5 sseparattor iisshiigherrtthaan that of the Z/PAN-0 separator, which is ascribed to the multistage pore structure inside tthatoffttheZ/PAN-0 separator,whichisascribedttotthemullttiissttageporressttrrucctturreiinssiidee ZSM-5 nanoparticles allowing more liquid electrolyte to be stored, as well as facilitating ZSM-5 nanoparticles allowing more liquid electrolyte to be sttored,,assweelllaassffaacciilliittaattiing the migration of lithium-ion. Considering the satisfactory tensile strength and excellent tthe miigratiion off lliitthiium--iion.. Considering the sattiisffactory ttensiille ssttrrengtth and eexxcceellleentt ion conductivity, the Z/PAN-1.5 separator was chosen as a typical sample of the Z/PAN iion conducttiiviitty,,tthheeZZ//PAN-1..5 separator was cchossenaassaatytyppicicaallssaamppleleoof fththeeZZ//PAN separators for succeeding studies. separattors ffor succeediing ssttudiiess.. −1−1 Figure 4. AC impedance spectra of the symmetric stainless-steel cells of different separators. Figure 4. AC impedance spectra of the symmetric stainless-steel cells of different separators. Figure 4. AC impedance spectra of the symmetric stainless-steel cells of different separators.PDF Image | Electrospinning Polyacrylonitrile Separator with Dip-Coating of Zeolite

PDF Search Title:

Electrospinning Polyacrylonitrile Separator with Dip-Coating of ZeoliteOriginal File Name Searched:

membranes-11-00267.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |