PDF Publication Title:

Text from PDF Page: 012

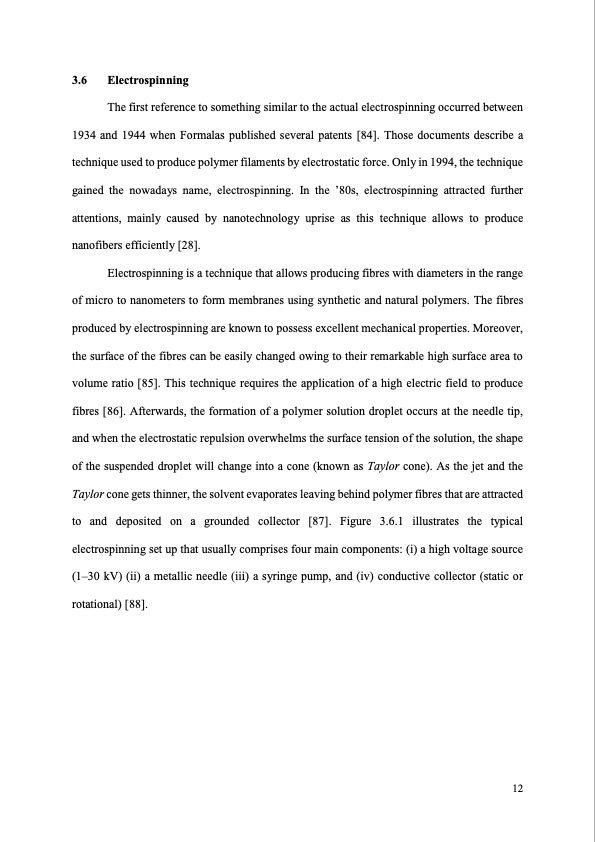

3.6 Electrospinning The first reference to something similar to the actual electrospinning occurred between 1934 and 1944 when Formalas published several patents [84]. Those documents describe a technique used to produce polymer filaments by electrostatic force. Only in 1994, the technique gained the nowadays name, electrospinning. In the ’80s, electrospinning attracted further attentions, mainly caused by nanotechnology uprise as this technique allows to produce nanofibers efficiently [28]. Electrospinning is a technique that allows producing fibres with diameters in the range of micro to nanometers to form membranes using synthetic and natural polymers. The fibres produced by electrospinning are known to possess excellent mechanical properties. Moreover, the surface of the fibres can be easily changed owing to their remarkable high surface area to volume ratio [85]. This technique requires the application of a high electric field to produce fibres [86]. Afterwards, the formation of a polymer solution droplet occurs at the needle tip, and when the electrostatic repulsion overwhelms the surface tension of the solution, the shape of the suspended droplet will change into a cone (known as Taylor cone). As the jet and the Taylor cone gets thinner, the solvent evaporates leaving behind polymer fibres that are attracted to and deposited on a grounded collector [87]. Figure 3.6.1 illustrates the typical electrospinning set up that usually comprises four main components: (i) a high voltage source (1–30 kV) (ii) a metallic needle (iii) a syringe pump, and (iv) conductive collector (static or rotational) [88]. 12PDF Image | Synthetic Polymer-based Membrane for Lithium Ion

PDF Search Title:

Synthetic Polymer-based Membrane for Lithium IonOriginal File Name Searched:

C11.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |