PDF Publication Title:

Text from PDF Page: 008

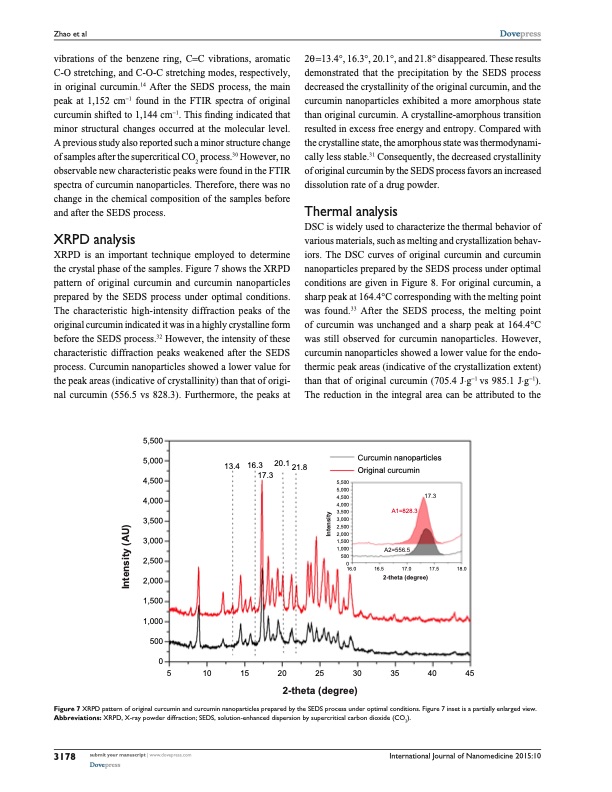

Zhao et al Dovepress vibrations of the benzene ring, C=C vibrations, aromatic C-O stretching, and C-O-C stretching modes, respectively, in original curcumin.14 After the SEDS process, the main peak at 1,152 cm-1 found in the FTIR spectra of original curcumin shifted to 1,144 cm-1. This finding indicated that minor structural changes occurred at the molecular level. A previous study also reported such a minor structure change of samples after the supercritical CO observable new characteristic peaks were found in the FTIR spectra of curcumin nanoparticles. Therefore, there was no change in the chemical composition of the samples before and after the SEDS process. XrPD analysis XRPD is an important technique employed to determine the crystal phase of the samples. Figure 7 shows the XRPD pattern of original curcumin and curcumin nanoparticles prepared by the SEDS process under optimal conditions. The characteristic high-intensity diffraction peaks of the original curcumin indicated it was in a highly crystalline form before the SEDS process.32 However, the intensity of these characteristic diffraction peaks weakened after the SEDS process. Curcumin nanoparticles showed a lower value for the peak areas (indicative of crystallinity) than that of origi- nal curcumin (556.5 vs 828.3). Furthermore, the peaks at 2θ =13.4°, 16.3°, 20.1°, and 21.8° disappeared. These results demonstrated that the precipitation by the SEDS process decreased the crystallinity of the original curcumin, and the curcumin nanoparticles exhibited a more amorphous state than original curcumin. A crystalline-amorphous transition resulted in excess free energy and entropy. Compared with the crystalline state, the amorphous state was thermodynami- cally less stable.31 Consequently, the decreased crystallinity of original curcumin by the SEDS process favors an increased dissolution rate of a drug powder. Thermal analysis DSC is widely used to characterize the thermal behavior of various materials, such as melting and crystallization behav- iors. The DSC curves of original curcumin and curcumin nanoparticles prepared by the SEDS process under optimal conditions are given in Figure 8. For original curcumin, a sharp peak at 164.4°C corresponding with the melting point was found.33 After the SEDS process, the melting point of curcumin was unchanged and a sharp peak at 164.4°C was still observed for curcumin nanoparticles. However, curcumin nanoparticles showed a lower value for the endo- thermic peak areas (indicative of the crystallization extent) than that of original curcumin (705.4 J⋅g-1 vs 985.1 J⋅g-1). The reduction in the integral area can be attributed to the ����� ����� ����� ����� ����� ����� ����� ����� ����� ����� ��� ���� ���� ���� ���� ���� �������� ������������� �������� �������� 2 process.30 However, no � � �� �� �� �� �� �� �� �� ������� �������� Figure 7 XrPD pattern of original curcumin and curcumin nanoparticles prepared by the seDs process under optimal conditions. Figure 7 inset is a partially enlarged view. Abbreviations: XrPD, X-ray powder diffraction; seDs, solution-enhanced dispersion by supercritical carbon dioxide (cO2). ����� ����� ����� ����� ����� ����� ����� ����� ����� ����� ��� � ���� ���� �������� �������� ���� ���� ���� ���� ������� �������� 3178 submit your manuscript | www.dovepress.com Dovepress International Journal of Nanomedicine 2015:10 ��������� ���� ���������PDF Image | curcumin nanoparticles via dispersion by supercritical cO2

PDF Search Title:

curcumin nanoparticles via dispersion by supercritical cO2Original File Name Searched:

cucumin-nanoparticles-co2.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |