PDF Publication Title:

Text from PDF Page: 004

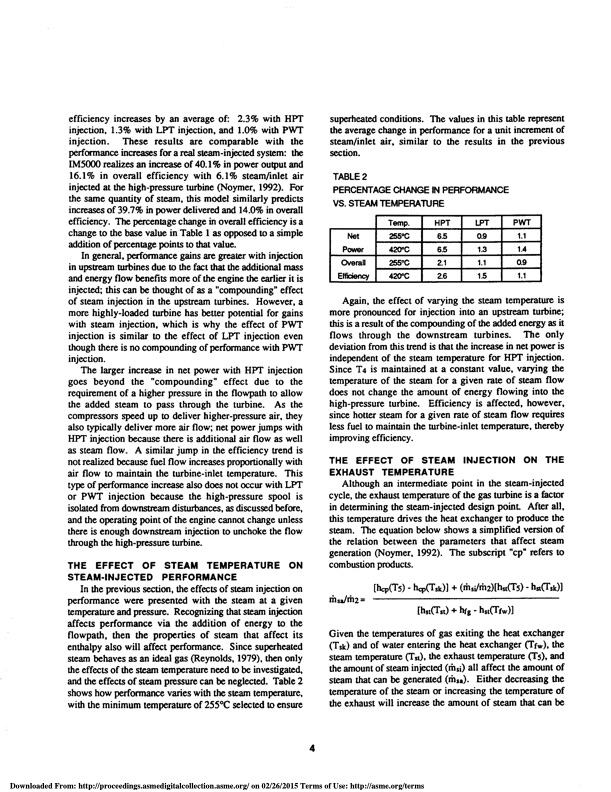

efficiency increases by an average of: 2.3% with HPT injection, 1.3% with LPT injection, and 1.0% with PWT injection. These results are comparable with the performance increases for a real steam-injected system: the IM5000 realizes an increase of 40.1% in power output and 16.1% in overall efficiency with 6.1% steam/inlet air injected at the high-pressure turbine (Noymer, 1992). For the same quantity of steam, this model similarly predicts increases of 39.7% in power delivered and 14.0% in overall efficiency. The percentage change in overall efficiency is a change to the base value in Table I as opposed to a simple addition of percentage points to that value. In general, performance gains are greater with injection in upstream turbines due to the fact that the additional mass and energy flow benefits more of the engine the earlier it is injected; this can be thought of as a "compounding" effect of steam injection in the upstream turbines. However, a more highly-loaded turbine has better potential for gains with steam injection, which is why the effect of PWT injection is similar to the effect of LPT injection even though there is no compounding of performance with PWT injection. The larger increase in net power with HPT injection goes beyond the "compounding" effect due to the requirement of a higher pressure in the flowpath to allow the added steam to pass through the turbine. As the compressors speed up to deliver higher-pressure air, they also typically deliver more air flow; net power jumps with HPT injection because there is additional air flow as well as steam flow. A similar jump in the efficiency trend is not realized because fuel flow increases proportionally with air flow to maintain the turbine-inlet temperature. This type of performance increase also does not occur with LPT or PWT injection because the high-pressure spool is isolated from downstream disturbances, as discussed before, and the operating point of the engine cannot change unless there is enough downstream injection to unchoke the flow through the high-pressure turbine. THE EFFECT OF STEAM TEMPERATURE ON STEAM-INJECTED PERFORMANCE In the previous section, the effects of steam injection on performance were presented with the steam at a given temperature and pressure. Recognizing that steam injection affects performance via the addition of energy to the flowpath, then the properties of steam that affect its enthalpy also will affect performance. Since superheated steam behaves as an ideal gas (Reynolds, 1979), then only the effects of the steam temperature need to be investigated, and the effects of steam pressure can be neglected. Table 2 shows how performance varies with the steam temperature, with the minimum temperature of 255 °C selected to ensure 4 superheated conditions. The values in this table represent the average change in performance for a unit increment of steam/inlet air, similar to the results in the previous section. TABLE 2 PERCENTAGE CHANGE IN PERFORMANCE VS. STEAM TEMPERATURE Net Power Overall Efficiency 255°C 6.5 420°C 6.5 255°C 2.1 420°C 2.6 0.9 1.1 1.3 1.4 1.1 0.9 1.5 1.1 1hsa/rh2 = [hcp(T5) - hcp(Tsk)] + (msi/m2)[hst(T5) - hst(Tsk)] [hst(Tsc) + hfg - hst(Tfw)] Temp. HPT LPT PWT Again, the effect of varying the steam temperature is more pronounced for injection into an upstream turbine; this is a result of the compounding of the added energy as it flows through the downstream turbines. The only deviation from this trend is that the increase in net power is independent of the steam temperature for HPT injection. Since T4 is maintained at a constant value, varying the temperature of the steam for a given rate of steam flow does not change the amount of energy flowing into the high-pressure turbine. Efficiency is affected, however, since hotter steam for a given rate of steam flow requires less fuel to maintain the turbine-inlet temperature, thereby improving efficiency. THE EFFECT OF STEAM INJECTION ON THE EXHAUST TEMPERATURE Although an intermediate point in the steam-injected cycle, the exhaust temperature of the gas turbine is a factor in determining the steam-injected design point. After all, this temperature drives the heat exchanger to produce the steam. The equation below shows a simplified version of the relation between the parameters that affect steam generation (Noymer, 1992). The subscript "cp" refers to combustion products. Given the temperatures of gas exiting the heat exchanger (Tsk) and of water entering the heat exchanger (Tfw), the steam temperature (Tst), the exhaust temperature (TS), and the amount of steam injected (rhsi) all affect the amount of ,). Either decreasing the steam that can be generated (m temperature of the steam or increasing the temperature of the exhaust will increase the amount of steam that can be : Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 02/26/2015 Terms of Use: http://asme.org/termsPDF Image | Thermodynamic Design Considerations Steam injected gas turbines

PDF Search Title:

Thermodynamic Design Considerations Steam injected gas turbinesOriginal File Name Searched:

steam-injected-gas-turbine.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |