PDF Publication Title:

Text from PDF Page: 008

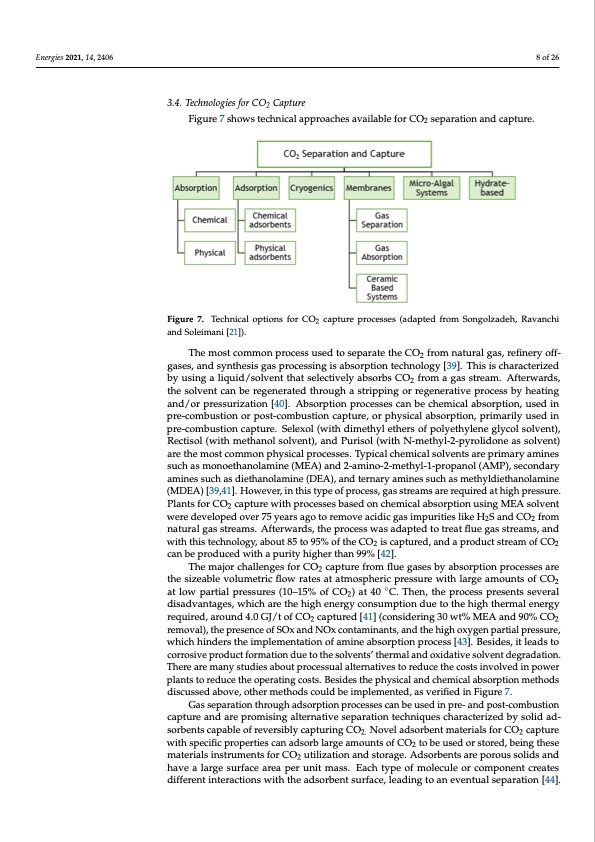

Energies 2021, 14, 2406 8 of 26 3.4. Technologies for CO2 Capture Figure 7 shows technical approaches available for CO2 separation and capture. Figure 7. Technical options for CO2 capture processes (adapted from Songolzadeh, Ravanchi and Soleimani [21]). The most common process used to separate the CO2 from natural gas, refinery off- gases, and synthesis gas processing is absorption technology [39]. This is characterized by using a liquid/solvent that selectively absorbs CO2 from a gas stream. Afterwards, the solvent can be regenerated through a stripping or regenerative process by heating and/or pressurization [40]. Absorption processes can be chemical absorption, used in pre-combustion or post-combustion capture, or physical absorption, primarily used in pre-combustion capture. Selexol (with dimethyl ethers of polyethylene glycol solvent), Rectisol (with methanol solvent), and Purisol (with N-methyl-2-pyrolidone as solvent) are the most common physical processes. Typical chemical solvents are primary amines such as monoethanolamine (MEA) and 2-amino-2-methyl-1-propanol (AMP), secondary amines such as diethanolamine (DEA), and ternary amines such as methyldiethanolamine (MDEA) [39,41]. However, in this type of process, gas streams are required at high pressure. Plants for CO2 capture with processes based on chemical absorption using MEA solvent were developed over 75 years ago to remove acidic gas impurities like H2S and CO2 from natural gas streams. Afterwards, the process was adapted to treat flue gas streams, and with this technology, about 85 to 95% of the CO2 is captured, and a product stream of CO2 can be produced with a purity higher than 99% [42]. The major challenges for CO2 capture from flue gases by absorption processes are the sizeable volumetric flow rates at atmospheric pressure with large amounts of CO2 at low partial pressures (10–15% of CO2) at 40 ◦C. Then, the process presents several disadvantages, which are the high energy consumption due to the high thermal energy required, around 4.0 GJ/t of CO2 captured [41] (considering 30 wt% MEA and 90% CO2 removal), the presence of SOx and NOx contaminants, and the high oxygen partial pressure, which hinders the implementation of amine absorption process [43]. Besides, it leads to corrosive product formation due to the solvents’ thermal and oxidative solvent degradation. There are many studies about processual alternatives to reduce the costs involved in power plants to reduce the operating costs. Besides the physical and chemical absorption methods discussed above, other methods could be implemented, as verified in Figure 7. Gas separation through adsorption processes can be used in pre- and post-combustion capture and are promising alternative separation techniques characterized by solid ad- sorbents capable of reversibly capturing CO2. Novel adsorbent materials for CO2 capture with specific properties can adsorb large amounts of CO2 to be used or stored, being these materials instruments for CO2 utilization and storage. Adsorbents are porous solids and have a large surface area per unit mass. Each type of molecule or component creates different interactions with the adsorbent surface, leading to an eventual separation [44].PDF Image | Current Developments of Carbon Capture Storage

PDF Search Title:

Current Developments of Carbon Capture StorageOriginal File Name Searched:

energies-14-02406.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |