PDF Publication Title:

Text from PDF Page: 005

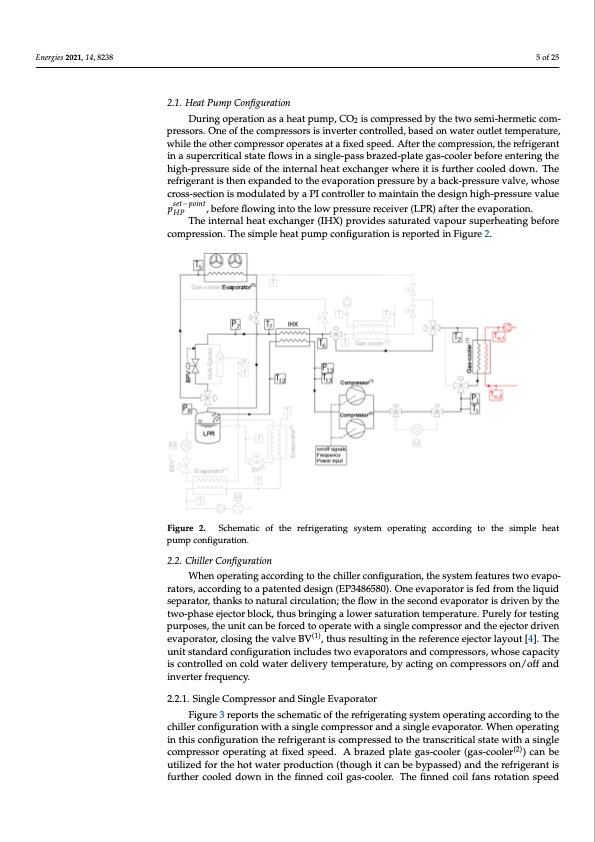

Energies 2021, 14, 8238 5 of 25 2.1. Heat Pump Configuration During operation as a heat pump, CO2 is compressed by the two semi-hermetic com- pressors. One of the compressors is inverter controlled, based on water outlet temperature, while the other compressor operates at a fixed speed. After the compression, the refrigerant in a supercritical state flows in a single-pass brazed-plate gas-cooler before entering the high-pressure side of the internal heat exchanger where it is further cooled down. The refrigerant is then expanded to the evaporation pressure by a back-pressure valve, whose cross-section is modulated by a PI controller to maintain the design high-pressure value pset−point, before flowing into the low pressure receiver (LPR) after the evaporation. The internal heat exchanger (IHX) provides saturated vapour superheating before compression. The simple heat pump configuration is reported in Figure 2. Figure 2. Schematic of the refrigerating system operating according to the simple heat pump configuration. 2.2. Chiller Configuration When operating according to the chiller configuration, the system features two evapo- rators, according to a patented design (EP3486580). One evaporator is fed from the liquid separator, thanks to natural circulation; the flow in the second evaporator is driven by the two-phase ejector block, thus bringing a lower saturation temperature. Purely for testing purposes, the unit can be forced to operate with a single compressor and the ejector driven evaporator, closing the valve BV(1), thus resulting in the reference ejector layout [4]. The unit standard configuration includes two evaporators and compressors, whose capacity is controlled on cold water delivery temperature, by acting on compressors on/off and inverter frequency. 2.2.1. Single Compressor and Single Evaporator Figure 3 reports the schematic of the refrigerating system operating according to the chiller configuration with a single compressor and a single evaporator. When operating in this configuration the refrigerant is compressed to the transcritical state with a single compressor operating at fixed speed. A brazed plate gas-cooler (gas-cooler(2)) can be utilized for the hot water production (though it can be bypassed) and the refrigerant is further cooled down in the finned coil gas-cooler. The finned coil fans rotation speed HPPDF Image | Dynamic Modelling and Validation of an Air-to-Water Reversible R744

PDF Search Title:

Dynamic Modelling and Validation of an Air-to-Water Reversible R744Original File Name Searched:

Artuso2021dma_publisert.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |