PDF Publication Title:

Text from PDF Page: 012

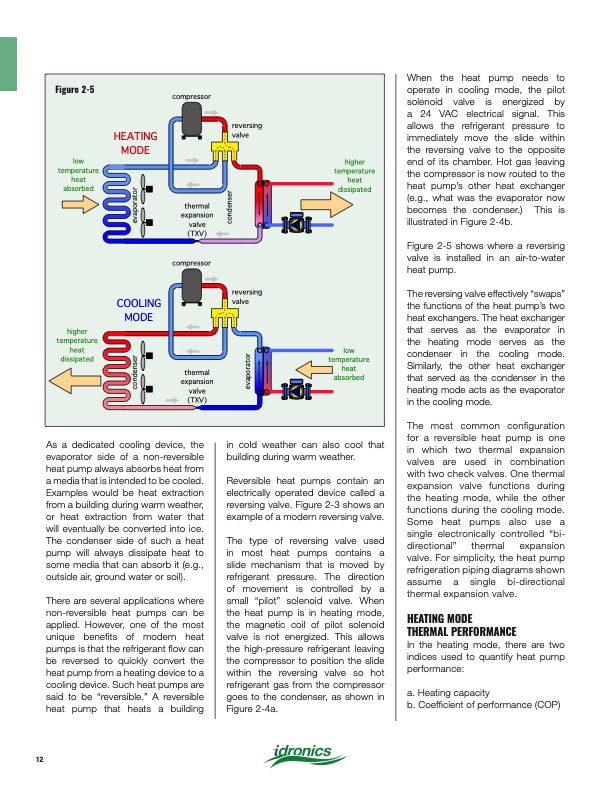

Figure 2-5 low temperature heat absorbed HEATING MODE compressor thermal expansion valve (TXV) compressor reversing valve higher temperature heat dissipated higher temperature heat dissipated thermal expansion valve (TXV) low temperature heat absorbed COOLING MODE reversing valve When the heat pump needs to operate in cooling mode, the pilot solenoid valve is energized by a 24 VAC electrical signal. This allows the refrigerant pressure to immediately move the slide within the reversing valve to the opposite end of its chamber. Hot gas leaving the compressor is now routed to the heat pump’s other heat exchanger (e.g., what was the evaporator now becomes the condenser.) This is illustrated in Figure 2-4b. Figure 2-5 shows where a reversing valve is installed in an air-to-water heat pump. The reversing valve effectively “swaps” the functions of the heat pump’s two heat exchangers. The heat exchanger that serves as the evaporator in the heating mode serves as the condenser in the cooling mode. Similarly, the other heat exchanger that served as the condenser in the heating mode acts as the evaporator in the cooling mode. The most common configuration for a reversible heat pump is one in which two thermal expansion valves are used in combination with two check valves. One thermal expansion valve functions during the heating mode, while the other functions during the cooling mode. Some heat pumps also use a single electronically controlled “bi- directional” thermal expansion valve. For simplicity, the heat pump refrigeration piping diagrams shown assume a single bi-directional thermal expansion valve. HEATING MODE THERMAL PERFORMANCE In the heating mode, there are two indices used to quantify heat pump performance: a. Heating capacity b. Coefficient of performance (COP) As a dedicated cooling device, the evaporator side of a non-reversible heat pump always absorbs heat from a media that is intended to be cooled. Examples would be heat extraction from a building during warm weather, or heat extraction from water that will eventually be converted into ice. The condenser side of such a heat pump will always dissipate heat to some media that can absorb it (e.g., outside air, ground water or soil). There are several applications where non-reversible heat pumps can be applied. However, one of the most unique benefits of modern heat pumps is that the refrigerant flow can be reversed to quickly convert the heat pump from a heating device to a cooling device. Such heat pumps are said to be “reversible.” A reversible heat pump that heats a building in cold weather can also cool that building during warm weather. Reversible heat pumps contain an electrically operated device called a reversing valve. Figure 2-3 shows an example of a modern reversing valve. The type of reversing valve used in most heat pumps contains a slide mechanism that is moved by refrigerant pressure. The direction of movement is controlled by a small “pilot” solenoid valve. When the heat pump is in heating mode, the magnetic coil of pilot solenoid valve is not energized. This allows the high-pressure refrigerant leaving the compressor to position the slide within the reversing valve so hot refrigerant gas from the compressor goes to the condenser, as shown in Figure 2-4a. condenser evaporator evaporator condenser 12PDF Image | Heat Pump Systems 2020

PDF Search Title:

Heat Pump Systems 2020Original File Name Searched:

idronics_27_na.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |