PDF Publication Title:

Text from PDF Page: 013

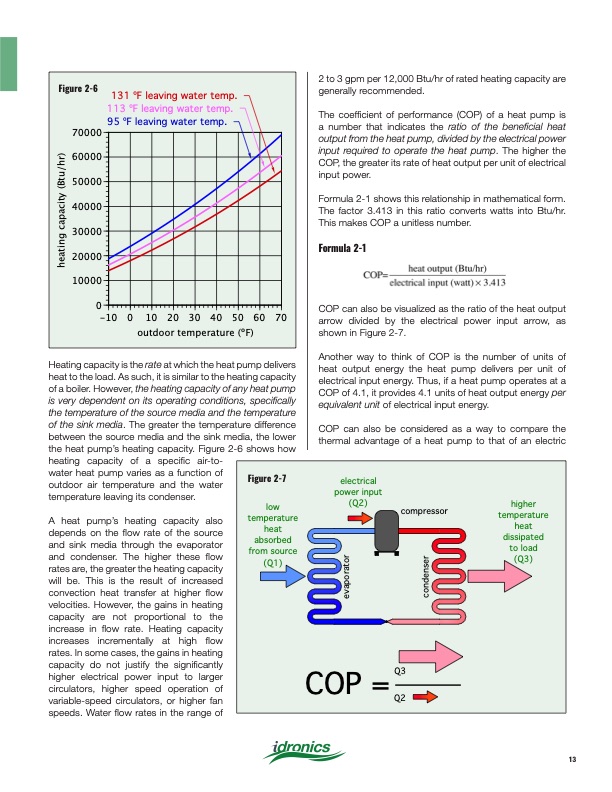

Figure 2-6 131 oF leaving water temp. 113 oF leaving water temp. 70000 95 oF leaving water temp. 60000 50000 40000 30000 20000 10000 0 -100 10203040506070 outdoor temperature (oF) Heating capacity is the rate at which the heat pump delivers heat to the load. As such, it is similar to the heating capacity of a boiler. However, the heating capacity of any heat pump is very dependent on its operating conditions, specifically the temperature of the source media and the temperature of the sink media. The greater the temperature difference between the source media and the sink media, the lower the heat pump’s heating capacity. Figure 2-6 shows how heating capacity of a specific air-to- water heat pump varies as a function of outdoor air temperature and the water temperature leaving its condenser. A heat pump’s heating capacity also depends on the flow rate of the source and sink media through the evaporator and condenser. The higher these flow rates are, the greater the heating capacity will be. This is the result of increased convection heat transfer at higher flow velocities. However, the gains in heating capacity are not proportional to the increase in flow rate. Heating capacity increases incrementally at high flow rates. In some cases, the gains in heating capacity do not justify the significantly higher electrical power input to larger circulators, higher speed operation of variable-speed circulators, or higher fan speeds. Water flow rates in the range of Another way toQthinckooolifngCcOapPacisty t(hBetu/nhru)mber of units of EER= c = 2 to 3 gpm per 12,000 Btu/hr of rated heating capacity are generally recommended. The coefficient of performance (COP) of a heat pump is a number that indicates the ratio of the beneficial heat output from the heat pump, divided by the electrical power input required to operate the heat pump. The higher the COP, the greater its rate of heat output per unit of electrical input power. Formula 2-1 shows this relationship in mathematical form. The factor 3.413 in this ratio converts watts into Btu/hr. This makes COP a unitless number. Formula 2-1 T COP can also be visualizesindk as the ratio of the heat output COP = Carnot arrow divided by t(hTesinke−leTcsoturciec)al power input arrow, as shown in Figure 2-7. heat output enewrgy ethleectrhiceaal itnpuut mwapttadgelivers per unit of e electrical input energy. Thus, if a heat pump operates at a COP of 4.1, it provides 4.1 units of heat output energy per equivalent unit of electrical input energy. COP = 48,000Btu / hr = 3.35 HPonly ⎡4200⎤ watt × 3.413 Btu / hr COP can also be co⎣nside⎦red as a way to compare the thermal advantage of a heat pump to that of an electric watt E =E − =39.9 − =4.22MMB Figure 2-7 low ! temperature! heat! absorbed! from source! (Q1) electrical 48,000Btu / hr ⎡⎣(2×220)+4200+180⎤⎦watt×3.413 watt COPnet = power input Btu/hr = higher ! temperature! heat! (Q2) COP HPonly COP = net compressor 4 /hr dissipated! 8,000Btu watt × 3.4 8,000Btu 0⎤watt× = 4 ⎡5500⎤ / hr 13 Btu / hr watt = 2.56 to load! ⎣ ⎦ (Q3) =2.48 ⎡⎣5500+18 ⎦ 3.413Btu/hr watt COP =⎡ 1 Q2 1 ⎤ ⎥ Es=ER⎢Q3 − ⎣COPL COPH ⎦ s R COP COP 2.5 3.4 ⎡11⎤⎡11⎤ ⎢⎣ L H⎥⎦ ⎢⎣ ⎥⎦ tu / season 13 2.92 evaporator condenser heating capacity (Btu/hr)PDF Image | Heat Pump Systems 2020

PDF Search Title:

Heat Pump Systems 2020Original File Name Searched:

idronics_27_na.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |