PDF Publication Title:

Text from PDF Page: 109

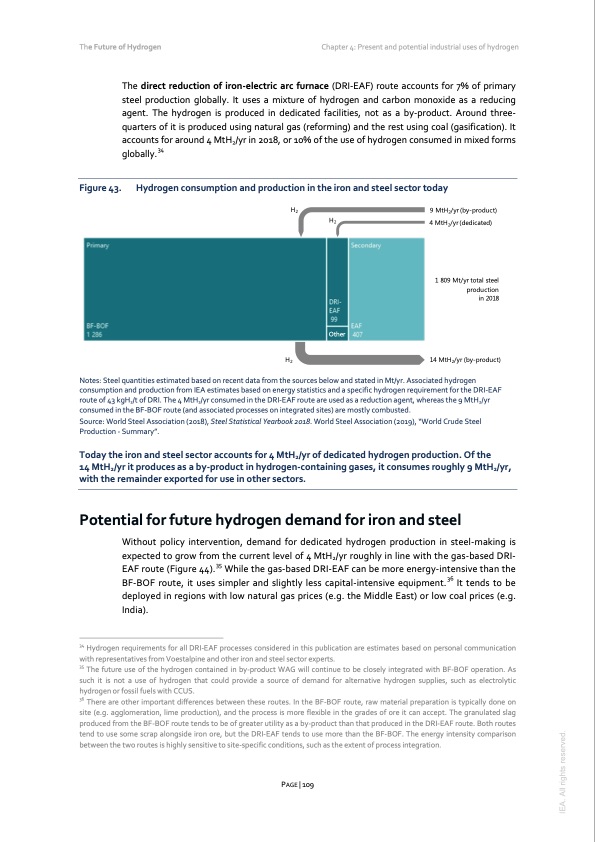

The Future of Hydrogen Chapter 4: Present and potential industrial uses of hydrogen Figure 43. The direct reduction of iron-electric arc furnace (DRI-EAF) route accounts for 7% of primary steel production globally. It uses a mixture of hydrogen and carbon monoxide as a reducing agent. The hydrogen is produced in dedicated facilities, not as a by-product. Around three- quarters of it is produced using natural gas (reforming) and the rest using coal (gasification). It accounts for around 4 MtH2/yr in 2018, or 10% of the use of hydrogen consumed in mixed forms globally.34 Hydrogen consumption and production in the iron and steel sector today H2 H2 9 MtH2/yr (by-product) 4 MtH2/yr (dedicated) 1 809 Mt/yr total steel production in 2018 14 MtH2/yr (by-product) Notes: Steel quantities estimated based on recent data from the sources below and stated in Mt/yr. Associated hydrogen consumption and production from IEA estimates based on energy statistics and a specific hydrogen requirement for the DRI-EAF route of 43 kgH2/t of DRI. The 4 MtH2/yr consumed in the DRI-EAF route are used as a reduction agent, whereas the 9 MtH2/yr consumed in the BF-BOF route (and associated processes on integrated sites) are mostly combusted. Source: World Steel Association (2018), Steel Statistical Yearbook 2018. World Steel Association (2019), “World Crude Steel Production - Summary”. Today the iron and steel sector accounts for 4 MtH2/yr of dedicated hydrogen production. Of the 14 MtH2/yr it produces as a by-product in hydrogen-containing gases, it consumes roughly 9 MtH2/yr, with the remainder exported for use in other sectors. Potential for future hydrogen demand for iron and steel Without policy intervention, demand for dedicated hydrogen production in steel-making is expected to grow from the current level of 4 MtH2/yr roughly in line with the gas-based DRI- EAF route (Figure 44).35 While the gas-based DRI-EAF can be more energy-intensive than the BF-BOF route, it uses simpler and slightly less capital-intensive equipment.36 It tends to be deployed in regions with low natural gas prices (e.g. the Middle East) or low coal prices (e.g. India). 34 Hydrogen requirements for all DRI-EAF processes considered in this publication are estimates based on personal communication with representatives from Voestalpine and other iron and steel sector experts. 35 The future use of the hydrogen contained in by-product WAG will continue to be closely integrated with BF-BOF operation. As such it is not a use of hydrogen that could provide a source of demand for alternative hydrogen supplies, such as electrolytic hydrogen or fossil fuels with CCUS. 36 There are other important differences between these routes. In the BF-BOF route, raw material preparation is typically done on site (e.g. agglomeration, lime production), and the process is more flexible in the grades of ore it can accept. The granulated slag produced from the BF-BOF route tends to be of greater utility as a by-product than that produced in the DRI-EAF route. Both routes tend to use some scrap alongside iron ore, but the DRI-EAF tends to use more than the BF-BOF. The energy intensity comparison between the two routes is highly sensitive to site-specific conditions, such as the extent of process integration. H2 Other PAGE | 109 IEA. All rights reserved.PDF Image | The Future of Hydrogen 2019

PDF Search Title:

The Future of Hydrogen 2019Original File Name Searched:

the_future_of_hydrogen.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |