PDF Publication Title:

Text from PDF Page: 004

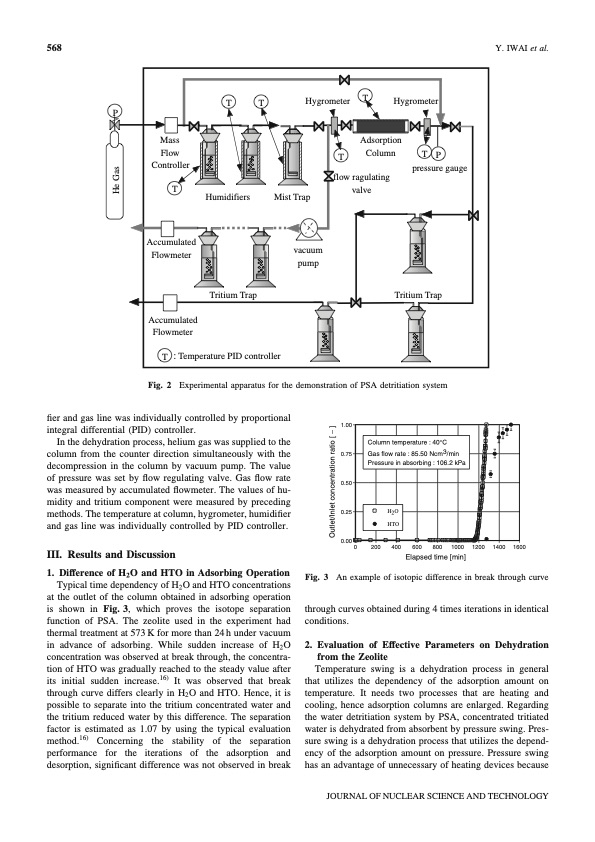

568 Y. IWAI et al. TT Humidifiers Tritium Trap Hygrometer T Hygrometer Mass Flow Controller T Accumulated Flowmeter Accumulated Flowmeter T Adsorption Column T P pressure gauge Mist Trap vacuum pump flow ragulating valve Tritium Trap T : Temperature PID controller P Fig. 2 Experimental apparatus for the demonstration of PSA detritiation system fier and gas line was individually controlled by proportional integral differential (PID) controller. In the dehydration process, helium gas was supplied to the column from the counter direction simultaneously with the decompression in the column by vacuum pump. The value of pressure was set by flow regulating valve. Gas flow rate was measured by accumulated flowmeter. The values of hu- midity and tritium component were measured by preceding methods. The temperature at column, hygrometer, humidifier and gas line was individually controlled by PID controller. III. Results and Discussion 1. Difference of H2O and HTO in Adsorbing Operation Typical time dependency of H2O and HTO concentrations at the outlet of the column obtained in adsorbing operation is shown in Fig. 3, which proves the isotope separation function of PSA. The zeolite used in the experiment had thermal treatment at 573 K for more than 24 h under vacuum in advance of adsorbing. While sudden increase of H2O concentration was observed at break through, the concentra- tion of HTO was gradually reached to the steady value after its initial sudden increase.16) It was observed that break through curve differs clearly in H2O and HTO. Hence, it is possible to separate into the tritium concentrated water and the tritium reduced water by this difference. The separation factor is estimated as 1.07 by using the typical evaluation method.16) Concerning the stability of the separation performance for the iterations of the adsorption and desorption, significant difference was not observed in break 1.00 0.75 0.50 0.25 H2O HTO 0.00 200 400 600 800 1000 1200 Elapsed time [min] An example of isotopic difference in break through curve Co lumn te mperat ° Gas flow rate : 85.50 Ncm3/min Pressure in absorbing : 106.2 kPa ure : 4 0C Fig. 3 0 1400 1600 through curves obtained during 4 times iterations in identical conditions. 2. Evaluation of Effective Parameters on Dehydration from the Zeolite Temperature swing is a dehydration process in general that utilizes the dependency of the adsorption amount on temperature. It needs two processes that are heating and cooling, hence adsorption columns are enlarged. Regarding the water detritiation system by PSA, concentrated tritiated water is dehydrated from absorbent by pressure swing. Pres- sure swing is a dehydration process that utilizes the depend- ency of the adsorption amount on pressure. Pressure swing has an advantage of unnecessary of heating devices because JOURNAL OF NUCLEAR SCIENCE AND TECHNOLOGY Outlet/Inlet concentration ratio [ − ] He GasPDF Image | Pressure Swing Adsorption to Water Detritiation Process

PDF Search Title:

Pressure Swing Adsorption to Water Detritiation ProcessOriginal File Name Searched:

PSA-Water-Detritiation-Process.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |