PDF Publication Title:

Text from PDF Page: 004

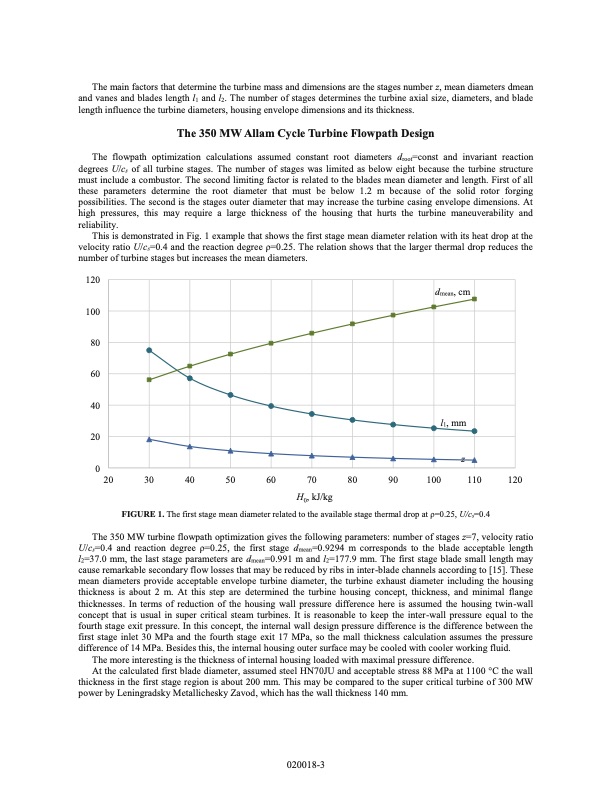

The main factors that determine the turbine mass and dimensions are the stages number z, mean diameters dmean and vanes and blades length l1 and l2. The number of stages determines the turbine axial size, diameters, and blade length influence the turbine diameters, housing envelope dimensions and its thickness. The 350 MW Allam Cycle Turbine Flowpath Design The flowpath optimization calculations assumed constant root diameters droot=const and invariant reaction degrees U/cs of all turbine stages. The number of stages was limited as below eight because the turbine structure must include a combustor. The second limiting factor is related to the blades mean diameter and length. First of all these parameters determine the root diameter that must be below 1.2 m because of the solid rotor forging possibilities. The second is the stages outer diameter that may increase the turbine casing envelope dimensions. At high pressures, this may require a large thickness of the housing that hurts the turbine maneuverability and reliability. This is demonstrated in Fig. 1 example that shows the first stage mean diameter relation with its heat drop at the velocity ratio U/cs=0.4 and the reaction degree ρ=0.25. The relation shows that the larger thermal drop reduces the number of turbine stages but increases the mean diameters. 120 100 80 60 40 20 0 dmean, cm l1, mm z 20 30 40 50 60 70 80 90 100 110 120 H0, kJ/kg FIGURE 1. The first stage mean diameter related to the available stage thermal drop at ρ=0.25, U/cs=0.4 The 350 MW turbine flowpath optimization gives the following parameters: number of stages z=7, velocity ratio U/cs=0.4 and reaction degree ρ=0.25, the first stage dmean=0.9294 m corresponds to the blade acceptable length l2=37.0 mm, the last stage parameters are dmean=0.991 m and l2=177.9 mm. The first stage blade small length may cause remarkable secondary flow losses that may be reduced by ribs in inter-blade channels according to [15]. These mean diameters provide acceptable envelope turbine diameter, the turbine exhaust diameter including the housing thickness is about 2 m. At this step are determined the turbine housing concept, thickness, and minimal flange thicknesses. In terms of reduction of the housing wall pressure difference here is assumed the housing twin-wall concept that is usual in super critical steam turbines. It is reasonable to keep the inter-wall pressure equal to the fourth stage exit pressure. In this concept, the internal wall design pressure difference is the difference between the first stage inlet 30 MPa and the fourth stage exit 17 MPa, so the mall thickness calculation assumes the pressure difference of 14 MPa. Besides this, the internal housing outer surface may be cooled with cooler working fluid. The more interesting is the thickness of internal housing loaded with maximal pressure difference. At the calculated first blade diameter, assumed steel HN70JU and acceptable stress 88 MPa at 1100 °C the wall thickness in the first stage region is about 200 mm. This may be compared to the super critical turbine of 300 MW power by Leningradsky Metallichesky Zavod, which has the wall thickness 140 mm. 020018-3PDF Image | design approach for supercritical CO2 gas turbine

PDF Search Title:

design approach for supercritical CO2 gas turbineOriginal File Name Searched:

1-5138630.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |