PDF Publication Title:

Text from PDF Page: 005

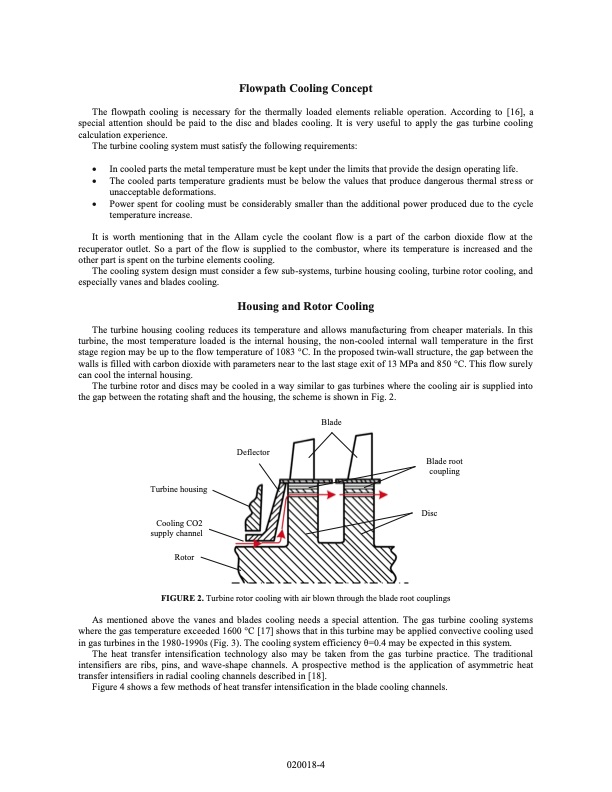

Flowpath Cooling Concept The flowpath cooling is necessary for the thermally loaded elements reliable operation. According to [16], a special attention should be paid to the disc and blades cooling. It is very useful to apply the gas turbine cooling calculation experience. The turbine cooling system must satisfy the following requirements: � In cooled parts the metal temperature must be kept under the limits that provide the design operating life. � The cooled parts temperature gradients must be below the values that produce dangerous thermal stress or unacceptable deformations. � Power spent for cooling must be considerably smaller than the additional power produced due to the cycle temperature increase. It is worth mentioning that in the Allam cycle the coolant flow is a part of the carbon dioxide flow at the recuperator outlet. So a part of the flow is supplied to the combustor, where its temperature is increased and the other part is spent on the turbine elements cooling. The cooling system design must consider a few sub-systems, turbine housing cooling, turbine rotor cooling, and especially vanes and blades cooling. Housing and Rotor Cooling The turbine housing cooling reduces its temperature and allows manufacturing from cheaper materials. In this turbine, the most temperature loaded is the internal housing, the non-cooled internal wall temperature in the first stage region may be up to the flow temperature of 1083 °C. In the proposed twin-wall structure, the gap between the walls is filled with carbon dioxide with parameters near to the last stage exit of 13 MPa and 850 °C. This flow surely can cool the internal housing. The turbine rotor and discs may be cooled in a way similar to gas turbines where the cooling air is supplied into the gap between the rotating shaft and the housing, the scheme is shown in Fig. 2. Deflector Blade root coupling Disc Blade Turbine housing Cooling CO2 supply channel Rotor FIGURE 2. Turbine rotor cooling with air blown through the blade root couplings As mentioned above the vanes and blades cooling needs a special attention. The gas turbine cooling systems where the gas temperature exceeded 1600 °C [17] shows that in this turbine may be applied convective cooling used in gas turbines in the 1980-1990s (Fig. 3). The cooling system efficiency θ=0.4 may be expected in this system. The heat transfer intensification technology also may be taken from the gas turbine practice. The traditional intensifiers are ribs, pins, and wave-shape channels. A prospective method is the application of asymmetric heat transfer intensifiers in radial cooling channels described in [18]. Figure 4 shows a few methods of heat transfer intensification in the blade cooling channels. 020018-4PDF Image | design approach for supercritical CO2 gas turbine

PDF Search Title:

design approach for supercritical CO2 gas turbineOriginal File Name Searched:

1-5138630.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |