PDF Publication Title:

Text from PDF Page: 003

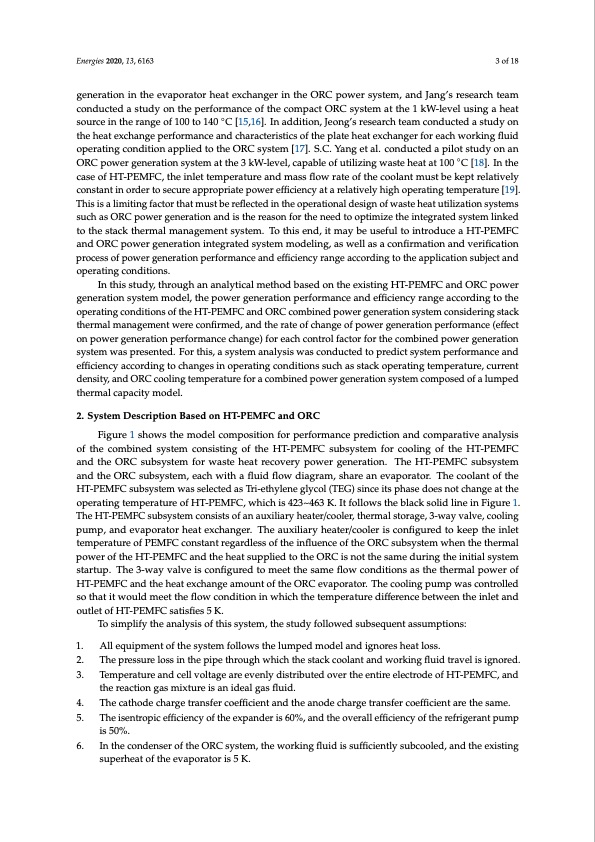

Energies 2020, 13, 6163 3 of 18 generation in the evaporator heat exchanger in the ORC power system, and Jang’s research team conducted a study on the performance of the compact ORC system at the 1 kW-level using a heat source in the range of 100 to 140 ◦C [15,16]. In addition, Jeong’s research team conducted a study on the heat exchange performance and characteristics of the plate heat exchanger for each working fluid operating condition applied to the ORC system [17]. S.C. Yang et al. conducted a pilot study on an ORC power generation system at the 3 kW-level, capable of utilizing waste heat at 100 ◦C [18]. In the case of HT-PEMFC, the inlet temperature and mass flow rate of the coolant must be kept relatively constant in order to secure appropriate power efficiency at a relatively high operating temperature [19]. This is a limiting factor that must be reflected in the operational design of waste heat utilization systems such as ORC power generation and is the reason for the need to optimize the integrated system linked to the stack thermal management system. To this end, it may be useful to introduce a HT-PEMFC and ORC power generation integrated system modeling, as well as a confirmation and verification process of power generation performance and efficiency range according to the application subject and operating conditions. In this study, through an analytical method based on the existing HT-PEMFC and ORC power generation system model, the power generation performance and efficiency range according to the operating conditions of the HT-PEMFC and ORC combined power generation system considering stack thermal management were confirmed, and the rate of change of power generation performance (effect on power generation performance change) for each control factor for the combined power generation system was presented. For this, a system analysis was conducted to predict system performance and efficiency according to changes in operating conditions such as stack operating temperature, current density, and ORC cooling temperature for a combined power generation system composed of a lumped thermal capacity model. 2. System Description Based on HT-PEMFC and ORC Figure 1 shows the model composition for performance prediction and comparative analysis of the combined system consisting of the HT-PEMFC subsystem for cooling of the HT-PEMFC and the ORC subsystem for waste heat recovery power generation. The HT-PEMFC subsystem and the ORC subsystem, each with a fluid flow diagram, share an evaporator. The coolant of the HT-PEMFC subsystem was selected as Tri-ethylene glycol (TEG) since its phase does not change at the operating temperature of HT-PEMFC, which is 423~463 K. It follows the black solid line in Figure 1. The HT-PEMFC subsystem consists of an auxiliary heater/cooler, thermal storage, 3-way valve, cooling pump, and evaporator heat exchanger. The auxiliary heater/cooler is configured to keep the inlet temperature of PEMFC constant regardless of the influence of the ORC subsystem when the thermal power of the HT-PEMFC and the heat supplied to the ORC is not the same during the initial system startup. The 3-way valve is configured to meet the same flow conditions as the thermal power of HT-PEMFC and the heat exchange amount of the ORC evaporator. The cooling pump was controlled so that it would meet the flow condition in which the temperature difference between the inlet and outlet of HT-PEMFC satisfies 5 K. To simplify the analysis of this system, the study followed subsequent assumptions: 1. All equipment of the system follows the lumped model and ignores heat loss. 2. The pressure loss in the pipe through which the stack coolant and working fluid travel is ignored. 3. Temperature and cell voltage are evenly distributed over the entire electrode of HT-PEMFC, and the reaction gas mixture is an ideal gas fluid. 4. The cathode charge transfer coefficient and the anode charge transfer coefficient are the same. 5. The isentropic efficiency of the expander is 60%, and the overall efficiency of the refrigerant pump is 50%. 6. In the condenser of the ORC system, the working fluid is sufficiently subcooled, and the existing superheat of the evaporator is 5 K.PDF Image | Combined Power Generation System Based on HT-PEMFC and ORC

PDF Search Title:

Combined Power Generation System Based on HT-PEMFC and ORCOriginal File Name Searched:

energies-13-06163-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |