PDF Publication Title:

Text from PDF Page: 009

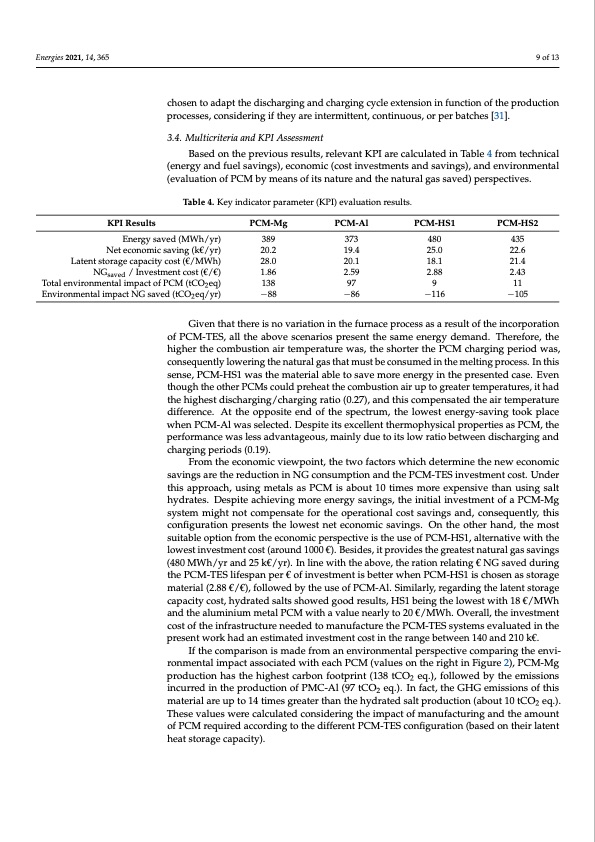

Energies 2021, 14, 365 9 of 13 KPI Results Table 4. Key indicator parameter (KPI) evaluation results. PCM-Mg PCM-Al PCM-HS1 PCM-HS2 chosen to adapt the discharging and charging cycle extension in function of the production processes, considering if they are intermittent, continuous, or per batches [31]. 3.4. Multicriteria and KPI Assessment Based on the previous results, relevant KPI are calculated in Table 4 from technical (energy and fuel savings), economic (cost investments and savings), and environmental (evaluation of PCM by means of its nature and the natural gas saved) perspectives. Energy saved (MWh/yr) Net economic saving (k€/yr) Latent storage capacity cost (€/MWh) NGsaved / Investment cost (€/€) Total environmental impact of PCM (tCO2eq) Environmental impact NG saved (tCO2eq/yr) 389 373 480 435 20.2 19.4 25.0 22.6 28.0 20.1 18.1 21.4 1.86 2.59 2.88 2.43 138 97 9 11 −88 −86 −116 −105 Given that there is no variation in the furnace process as a result of the incorporation of PCM-TES, all the above scenarios present the same energy demand. Therefore, the higher the combustion air temperature was, the shorter the PCM charging period was, consequently lowering the natural gas that must be consumed in the melting process. In this sense, PCM-HS1 was the material able to save more energy in the presented case. Even though the other PCMs could preheat the combustion air up to greater temperatures, it had the highest discharging/charging ratio (0.27), and this compensated the air temperature difference. At the opposite end of the spectrum, the lowest energy-saving took place when PCM-Al was selected. Despite its excellent thermophysical properties as PCM, the performance was less advantageous, mainly due to its low ratio between discharging and charging periods (0.19). From the economic viewpoint, the two factors which determine the new economic savings are the reduction in NG consumption and the PCM-TES investment cost. Under this approach, using metals as PCM is about 10 times more expensive than using salt hydrates. Despite achieving more energy savings, the initial investment of a PCM-Mg system might not compensate for the operational cost savings and, consequently, this configuration presents the lowest net economic savings. On the other hand, the most suitable option from the economic perspective is the use of PCM-HS1, alternative with the lowest investment cost (around 1000 €). Besides, it provides the greatest natural gas savings (480 MWh/yr and 25 k€/yr). In line with the above, the ration relating € NG saved during the PCM-TES lifespan per € of investment is better when PCM-HS1 is chosen as storage material (2.88 €/€), followed by the use of PCM-Al. Similarly, regarding the latent storage capacity cost, hydrated salts showed good results, HS1 being the lowest with 18 €/MWh and the aluminium metal PCM with a value nearly to 20 €/MWh. Overall, the investment cost of the infrastructure needed to manufacture the PCM-TES systems evaluated in the present work had an estimated investment cost in the range between 140 and 210 k€. If the comparison is made from an environmental perspective comparing the envi- ronmental impact associated with each PCM (values on the right in Figure 2), PCM-Mg production has the highest carbon footprint (138 tCO2 eq.), followed by the emissions incurred in the production of PMC-Al (97 tCO2 eq.). In fact, the GHG emissions of this material are up to 14 times greater than the hydrated salt production (about 10 tCO2 eq.). These values were calculated considering the impact of manufacturing and the amount of PCM required according to the different PCM-TES configuration (based on their latent heat storage capacity).PDF Image | Latent Heat Storage for Waste Heat Recovery in the Energy Industry

PDF Search Title:

Latent Heat Storage for Waste Heat Recovery in the Energy IndustryOriginal File Name Searched:

energies-14-00365-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |