PDF Publication Title:

Text from PDF Page: 008

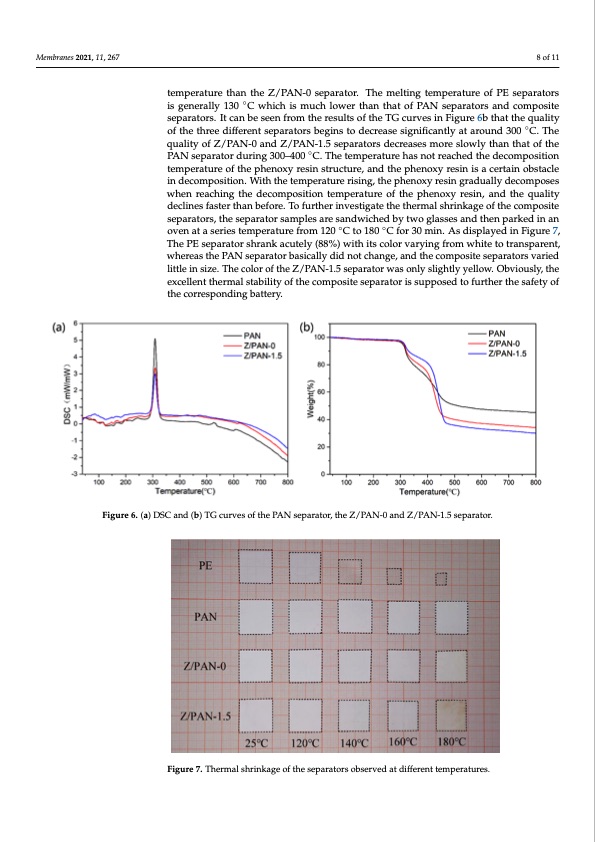

Membranes 2021, 11, 267 Membranes 2021, 11, x FOR PEER REVIEW 8 of 11 8 of 11 8 of 11 isgeneerraallly113300°CCwwhihcihchisims mucuhchlowloewretrhathnatnhatthoaft PoAf PNAsNepsaerpaatorrastoarnsdacnodmcpoomsipteosietpea- Membranes 2021, 11, x FOR PEER REVIEW temperature than the Z/PAN-0 separator. The melting temperature of PE separators ◦ generally 130 °C which is much lower than that of PAN separators and composite sepa- separators. It can be seen from the results of the TG curves in Figure 6b that the quality rators. It can be seen from the results of the TG curves in Figure 6b that the quality of the rators. It can be seen from the results of the TG curves in Figure 6b that the quality of the of the three different separators begins to decrease significantly at around 300 C. The three different separators begins to decrease significantly at around 300 °C. The quality of three different separators begins to decrease significantly at around 300 °C. The quality of quality of Z/PAN-0 and Z/PAN-1.5 separators decreases more slowly than that of the Z/PAN-0 and Z/PAN-1.5 separators decreases more slowly than that of the PAN separator ◦ tedmurpienrgat3u0r0e°oCf–t4h0e0p°hCe.nTohxeytreemsipnersatrtucretuhrea,sannodt rtehaecphhedentohxeydreecsoimn pisoasictieorntatienmopbesrtatculere of the phenoxy resin structure, and the phenoxy resin is a certain obstacle in decomposi- inofdtehceomphpeonsoitxiyonr.eWsinithstrthuecttuerme,paenrdatuthre prihsiengo,xtyherepshinenisoxaycerertsainingorabdstuaaclleyindedceocmompopsoesi- tion. With the temperature rising, the phenoxy resin gradually decomposes when reach- wtihoen. Wreaitchhtihneg ttehmepdeercaotumreporissiitniogn, ttheemppheernaotuxryereosfinthgerapdhueanlolyxyderceosimn,poasneds twhheeqnuraelaitcyh- ing the decomposition temperature of the phenoxy resin, and the quality declines faster diencglintheesfdaesctoermtphoasnitbioefnortem.Tpoefruatruthreroifntvheestpighaetneotxhyertheseirnm,alnsdhtrhinekqaugaeloitfythdecloinmepsofasister than before. To further investigate the thermal shrinkage of the composite separators, the sethpanrabteofrosr,et.hTeosefupratrhaetrorinsvaemstpigleasteartehesathnedrwmiaclhsehdribnyktawgeoogflathsseecsoamnpdotshietenspeaprakreadtoirns,atnhe separator samples are sandwiched by two glasses and then parked in an oven at a series TtheemPpEersaetpuareraftrormsh1r2a0n°kCatcou1te8l0y°(C88f%or)3w0imthinit.sAcosldoirspvlaryeindginfrFoimguwreh7it,eTthoetPraEnseppaarreantto,r shrank acutely (88%) with its color varying from white to transparent, whereas the PAN wsherraenaksathcuetPeAlyN(8s8e%pa)rwatiothr bitassiccoallolyr vdaidryninogt cfhroamngwe,haintedtohetrcaonmspaorseintet,swephaeraetaosrsthvearPiAedN separator basically did not change, and the composite separators varied little in size. The listetlpeairnastoizreb.aTshiceaclolylodriodfnthoet cZh/aPnAgNe,-a1n.5dsethpearcaotmorpwosaisteonselypaslriagthotrlsyvyaerlileodw.liOttblevinoussizlye,.tThhee color of the Z/PAN-1.5 separator was only slightly yellow. Obviously, the excellent ther- PZA/NPAsNep-a0rantodrZd/uPrAinNg-13.050s–e4p0a0ratCo.rsTdhectremaspeesrmatourreshloaws nlyothraenactheadt otfhtehedePcAoNmpseopsaitriaotnor during 300 °C–400 °C. The temperature has not reached the decomposition temperature ◦◦ osveepnaraattaorsesraimesptlems aprerastaunrdewfriochmed12b0y tCwtoog1l8a0sseCs afonrd3t0hemninp.aArksediisnplanyeodvein aFtigausrer7ie,s temperature from 120 °C to 180 °C for 30 min. As displayed in Figure 7, The PE separator excellent thermal stability of the composite separator is supposed to further the safety of color of the Z/PAN-1.5 separator was only slightly yellow. Obviously, the excellent ther- mal stability of the composite separator is supposed to further the safety of the corre- the corresponding battery. mal stability of the composite separator is supposed to further the safety of the corre- sponding battery. sponding battery. ◦ Figure 6. (a) DSC and (b) TG curves of the PAN separator, the Z/PAN-0 and Z/PAN-1.5 separator. Figure 6. (a) DSC and (b) TG curves of the PAN separator, the Z/PAN-0 and Z/PAN-1.5 separator. Figure 6. (a) DSC and (b) TG curves of the PAN separator, the Z/PAN-0 and Z/PAN-1.5 separator. Figure 7. Thermal shrinkage of the separators observed at different temperatures. Figure 7. Thermal shrinkage of the separators observed at different temperatures. Figure 7. Thermal shrinkage of the separators observed at different temperatures.PDF Image | Electrospinning Polyacrylonitrile Separator with Dip-Coating of Zeolite

PDF Search Title:

Electrospinning Polyacrylonitrile Separator with Dip-Coating of ZeoliteOriginal File Name Searched:

membranes-11-00267.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |