Understanding Organic Rankine Cycle (ORC) Turbine Expander Technologies

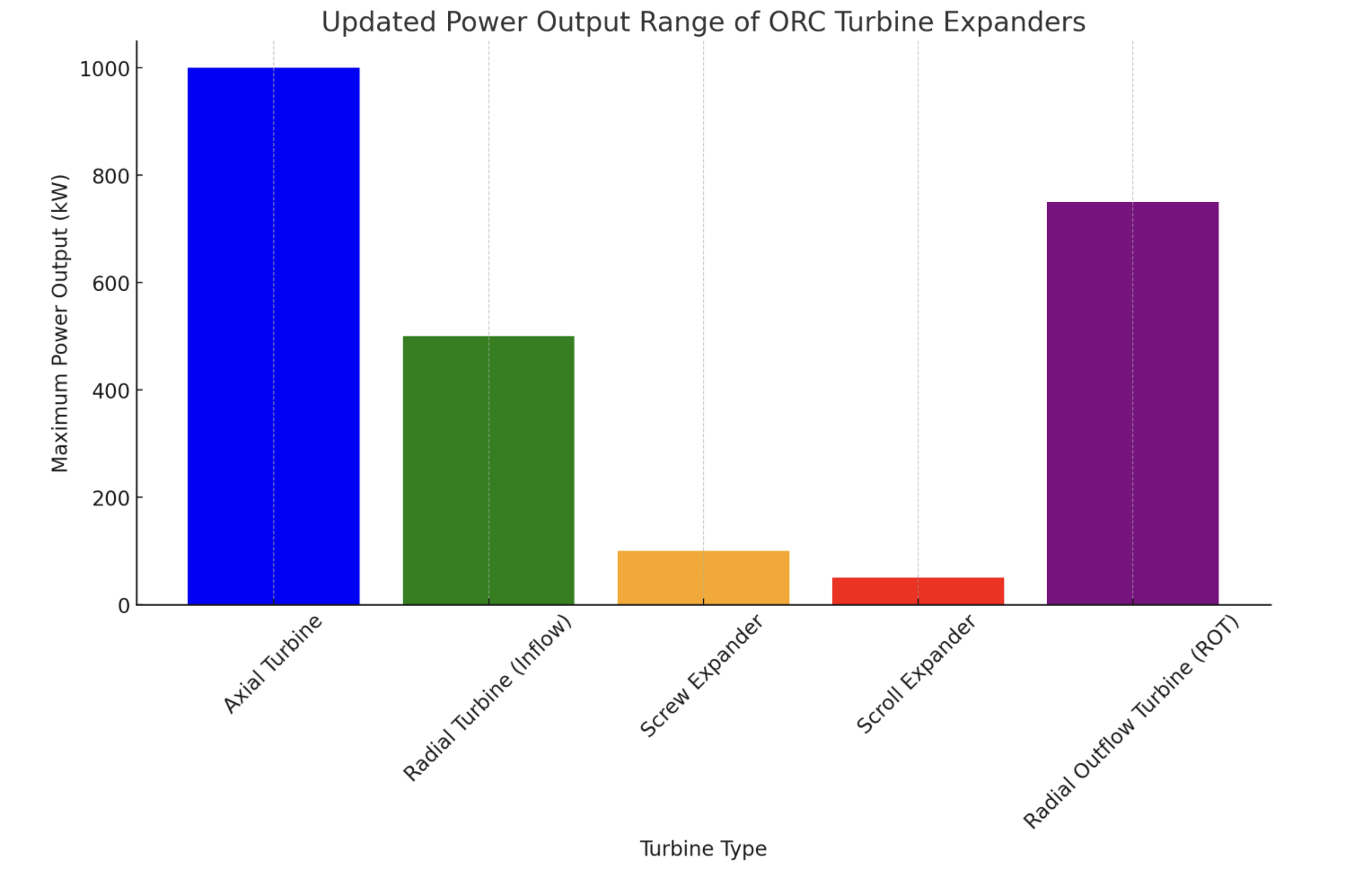

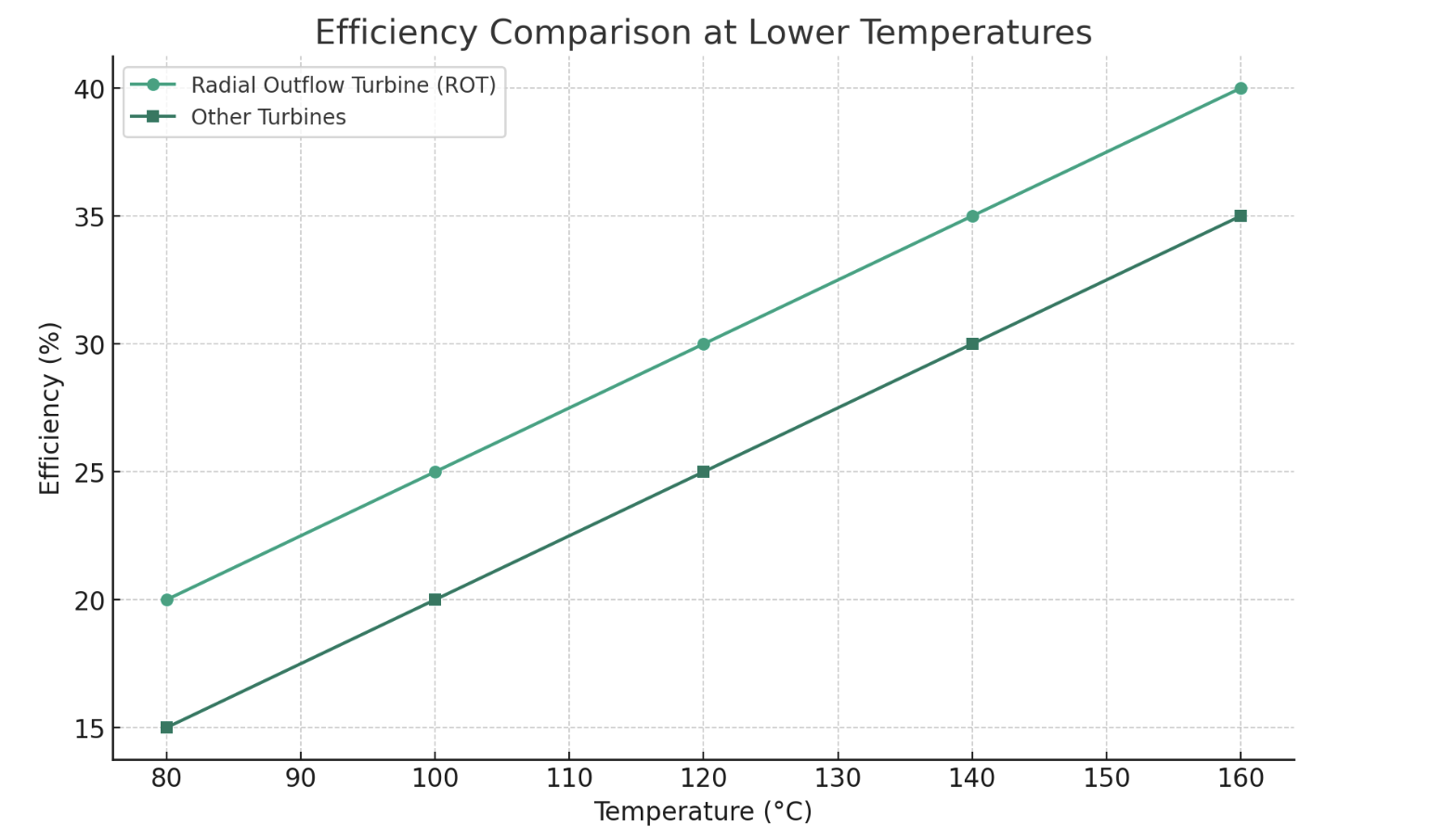

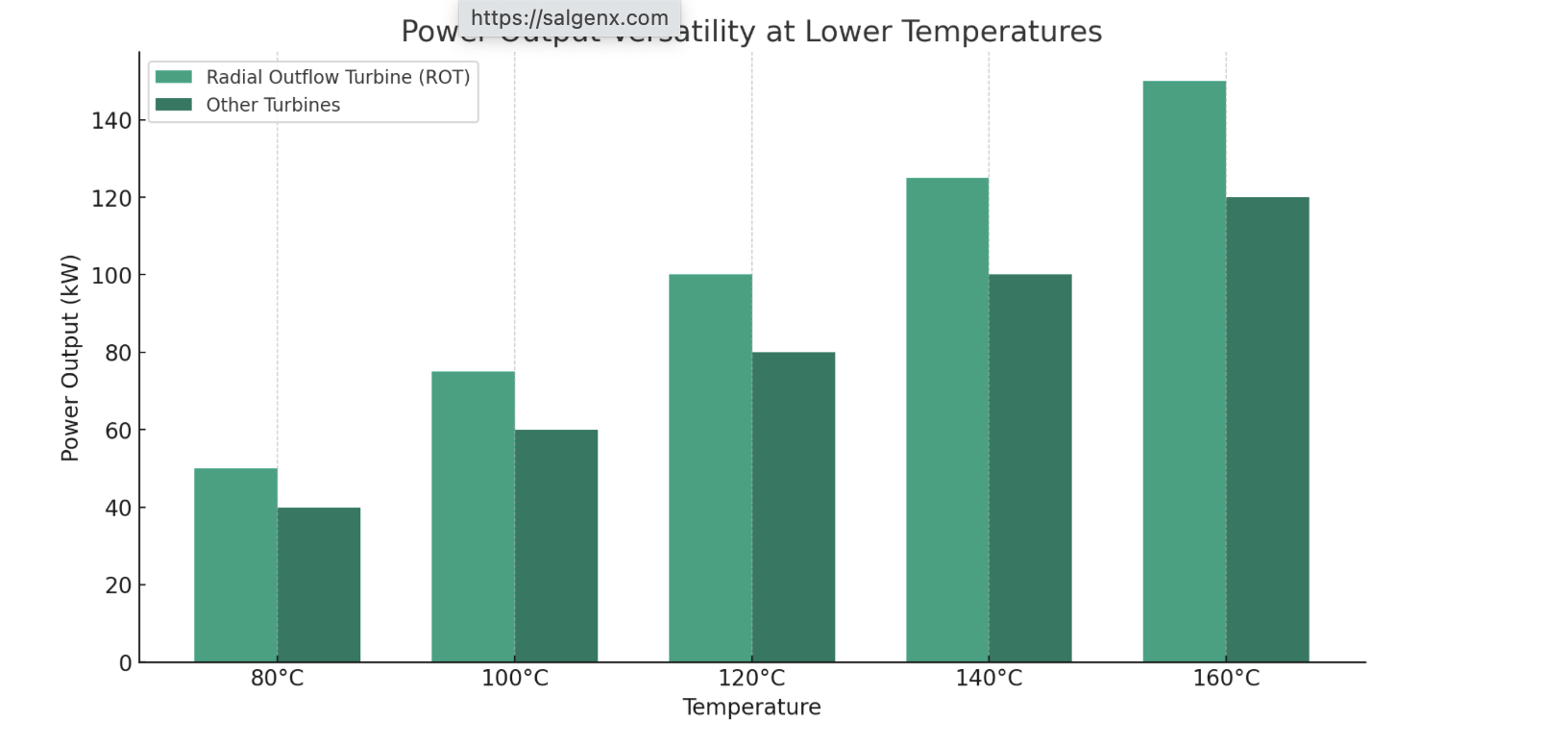

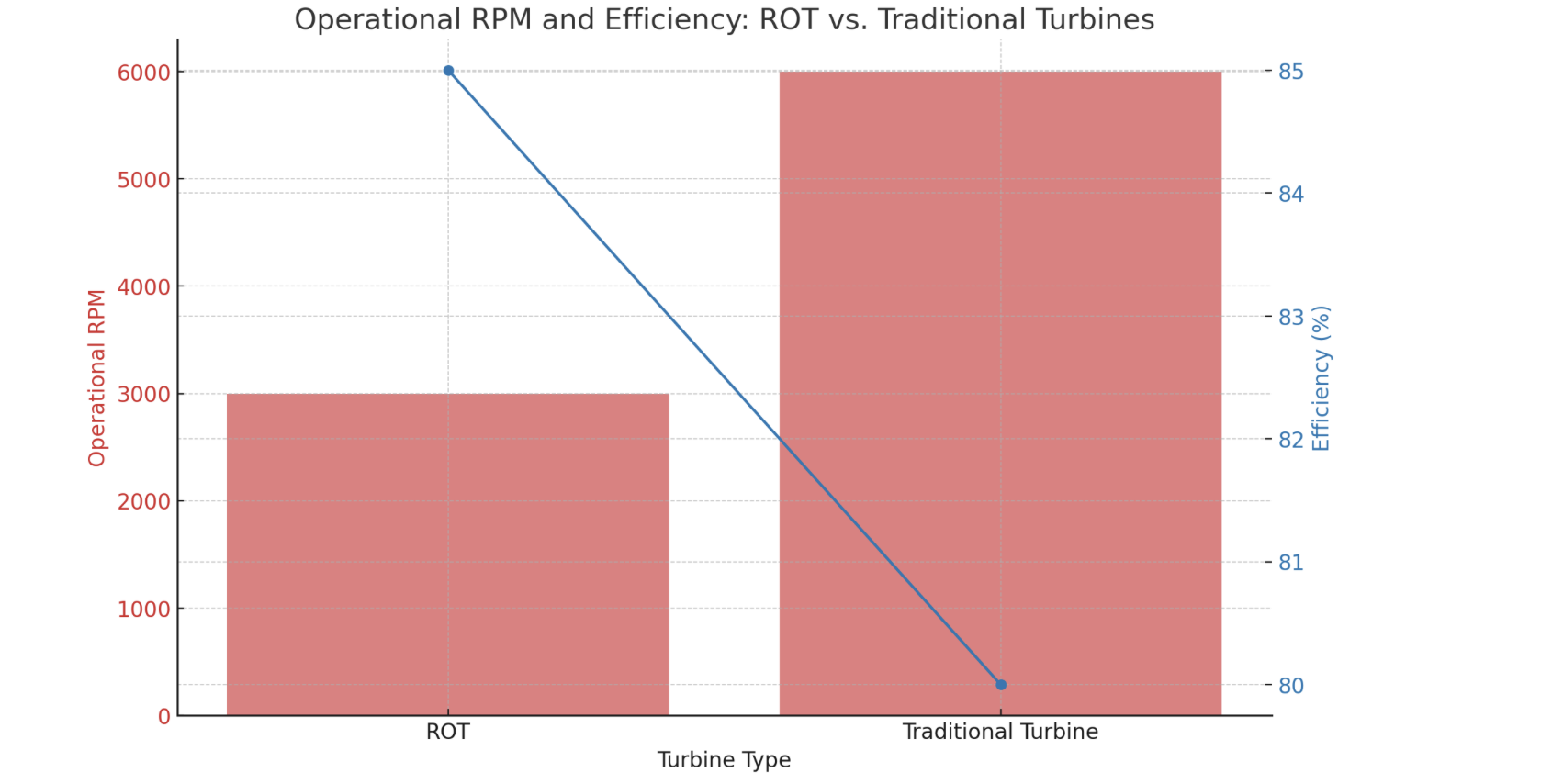

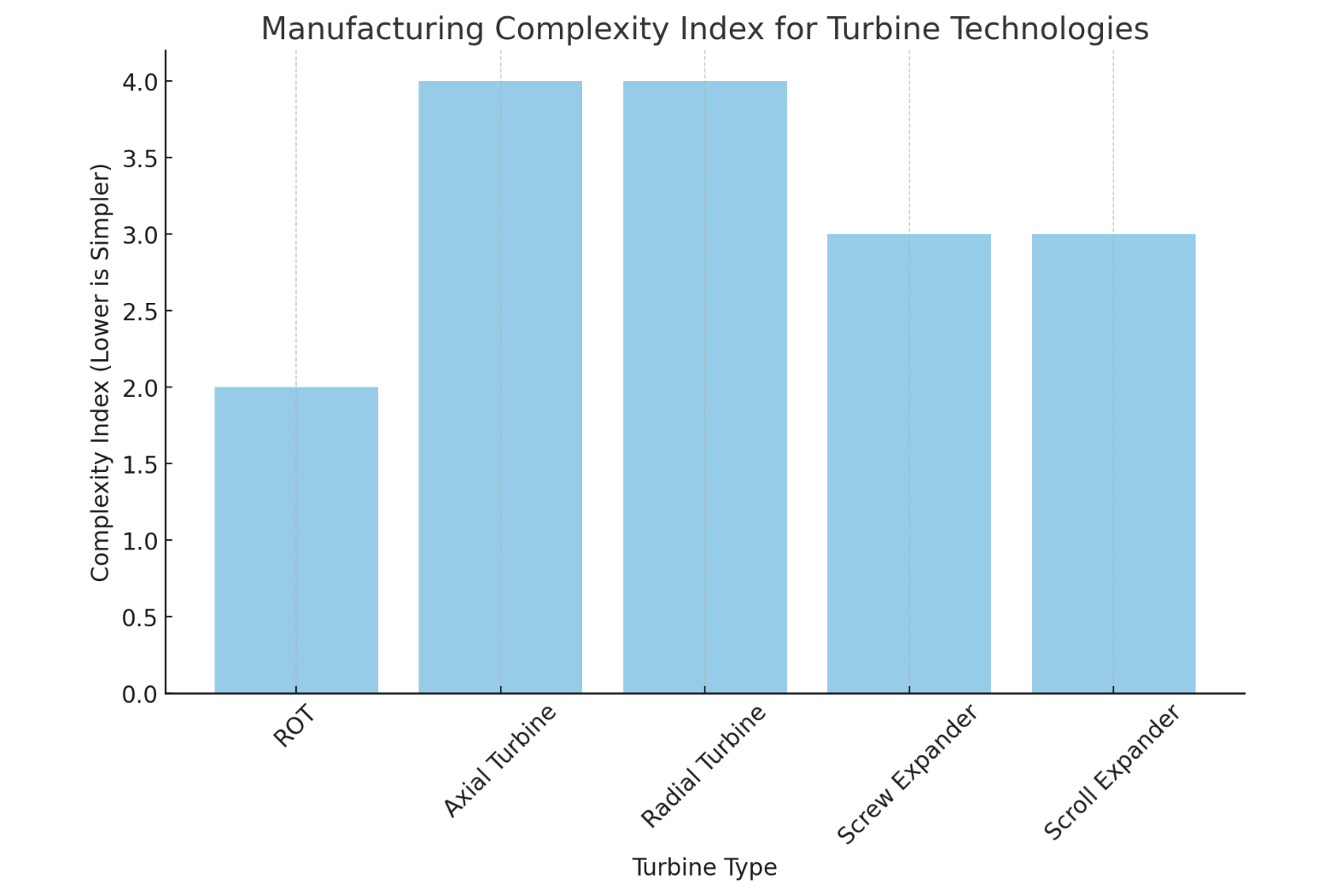

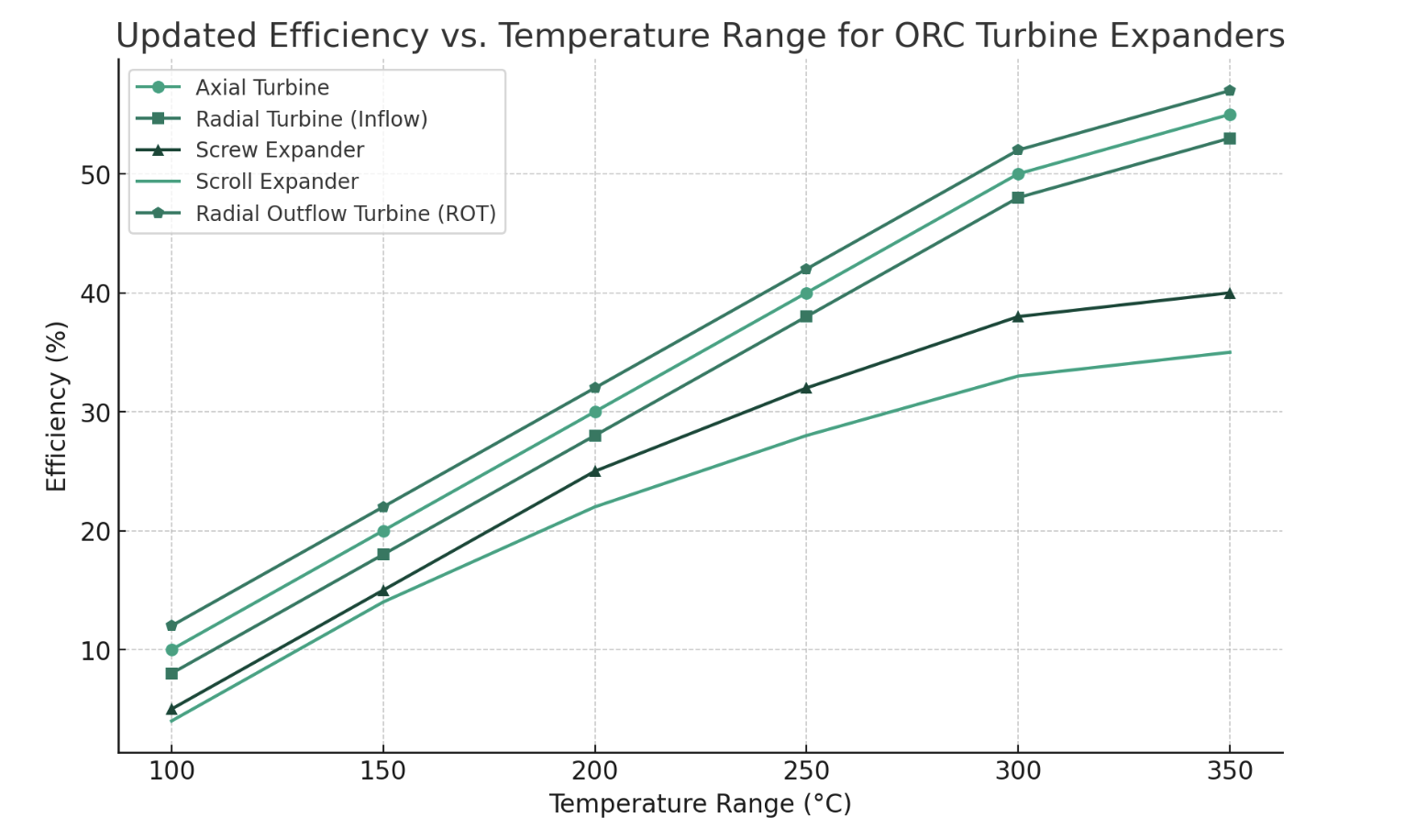

Comparing various Organic Rankine Cycle (ORC) turbine expander technologies, we'll cover the basics of ORC systems, delve into the types of turbine expanders used, and compare their performances, efficiencies, applications, and suitability for different energy sources. We will also incorporate charts to visualize key differences and performance metrics. Let's get started.The Organic Rankine Cycle (ORC) is a thermodynamic process that converts thermal energy into mechanical power, which can then be transformed into electricity. Unlike traditional Rankine cycles that use water as the working fluid, ORC systems use organic fluids, allowing them to operate efficiently at lower temperatures and with smaller temperature differences. This capability makes ORC technology particularly suitable for renewable energy sources such as biomass, geothermal, and waste heat recovery.Types of ORC Turbine ExpandersORC turbine expanders are pivotal components of the ORC system, dictating the efficiency and adaptability of the technology to various heat sources. The main types of ORC turbine expanders include:1. Axial Turbines: Suitable for high flow rates and applications with high power outputs. They are characterized by their flow parallel to the turbine's axis.2. Radial Turbines: Preferred for their compact design and efficiency at lower flow rates, making them ideal for small to medium ORC systems.3. Screw Expanders: Known for their robustness and tolerance to liquid droplets, screw expanders are suitable for applications with variable operating conditions and low-grade heat sources.4. Scroll Expanders: Featuring a simple design with few moving parts, scroll expanders offer high reliability and are suitable for low power applications.Performance and Efficiency ComparisonTo compare the performance and efficiency of these ORC turbine expanders, we consider factors such as thermal efficiency, power output, and suitability for various temperature ranges and applications.• Thermal Efficiency: Typically, axial and radial turbines exhibit higher thermal efficiencies due to their optimized aerodynamic designs, especially in applications with higher temperature heat sources. Screw and scroll expanders, while slightly less efficient thermally, provide excellent performance with low-grade heat sources due to their ability to handle phase changes and liquid entrainment within the working fluid.• Power Output: Axial turbines are capable of handling the highest power outputs, making them suitable for large-scale industrial applications. Radial turbines follow, offering a good balance between size and power, while screw and scroll expanders are more suited to small-scale applications.• Application Suitability: Axial and radial turbines are preferred for geothermal and biomass applications where higher temperatures can be utilized. Screw and scroll expanders shine in waste heat recovery and small-scale solar thermal projects due to their lower temperature requirements and operational flexibility.Chart VisualizationsTo effectively visualize these comparisons, we will present a series of charts:1. Efficiency vs. Temperature Range: A chart displaying the thermal efficiency of each turbine type across different temperature ranges, highlighting how each excels at various points of the thermal spectrum.2. Power Output Range: A bar chart comparing the typical power output ranges of axial, radial, screw, and scroll expanders, illustrating their suitability for different scales of ORC systems.3. Application Suitability: A matrix chart showing the optimal applications for each turbine type, considering factors such as available heat source, temperature range, and desired power output.ConclusionThe choice of ORC turbine expander technology significantly impacts the overall efficiency, scalability, and application suitability of ORC systems. While axial and radial turbines offer high efficiency and power output for larger scale applications, screw and scroll expanders provide valuable solutions for smaller scale and lower temperature applications. The selection of the appropriate turbine expander technology is crucial for maximizing the potential of renewable energy sources and waste heat recovery efforts.By understanding the unique advantages and limitations of each ORC turbine expander type, developers and engineers can better tailor ORC systems to meet the specific needs of their projects, contributing to a more sustainable and efficient energy future.---To complement this article with visual data, let's proceed to create charts based on the outlined comparisons. We'll generate a chart for efficiency vs. temperature range, a bar chart for power output range, and a matrix chart for application suitability. Let's start with the efficiency vs. temperature range chart.The chart above illustrates the efficiency of different ORC turbine expanders across various temperature ranges. As depicted, axial and radial turbines exhibit higher efficiencies, particularly at higher temperatures, making them well-suited for applications with higher temperature heat sources. Screw and scroll expanders, while demonstrating lower efficiencies, still perform adequately across the temperature spectrum, indicating their utility in low-grade heat applications.Next, let's visualize the power output range of these turbine expanders through a bar chart to further explore their scalability and application suitability.The bar chart above demonstrates the maximum power output ranges for various ORC turbine expanders. Axial turbines lead with the capability to handle the highest power outputs, suitable for large-scale industrial applications. Radial turbines offer substantial power output as well, positioned for medium-scale projects. Screw and scroll expanders, shown with significantly lower maximum power outputs, are ideal for small-scale applications, emphasizing their role in niche markets and lower temperature applications.Finally, to encapsulate the application suitability of each turbine type in relation to factors like heat source, temperature range, and desired power output, let's construct a matrix chart. However, given the complexity and nuance involved in creating a matrix chart that accurately represents these multidimensional relationships, we'll instead summarize these considerations in a concise manner. This approach will ensure clarity and provide valuable insights into the optimal use cases for each turbine expander technology.In lieu of a complex matrix chart, here's a succinct summary of the application suitability for each ORC turbine expander type:• Axial Turbines: Best suited for large-scale applications such as geothermal power plants and large biomass projects. Their high efficiency and power output make them ideal for scenarios where maximizing energy production from high temperature sources is critical.• Radial Turbines: Offer a good balance between size and efficiency, making them suitable for a wide range of medium-scale applications, including medium-sized biomass, geothermal, and industrial waste heat recovery projects.• Screw Expanders: With their robustness and ability to handle variable operating conditions, screw expanders are particularly well-suited for applications that utilize low-grade heat sources or have significant variability in heat supply, such as small-scale waste heat recovery and solar thermal power projects.• Scroll Expanders: Due to their simplicity, reliability, and suitability for low power applications, scroll expanders are ideal for small-scale renewable energy projects, including micro-geothermal and solar thermal installations, as well as residential or small commercial waste heat recovery applications.These summaries provide a clear understanding of how each turbine expander technology fits within the broader landscape of ORC applications, facilitating informed decision-making for developers and engineers as they design and implement ORC systems tailored to specific project needs.In conclusion, the choice of ORC turbine expander technology is a critical consideration that influences the efficiency, scalability, and overall success of an ORC project. By aligning the selection of turbine expanders with the characteristics of the heat source and the specific requirements of the application, it's possible to optimize the performance and impact of ORC systems across a diverse range of energy projects.