INFINITY TURBINE | SALES | DESIGN | DEVELOPMENT | ANALYSIS CONSULTING

TEL: +1-608-238-6001 (Chicago Time Zone ) Email: greg@infinityturbine.com

ElectraTherm 125 kWe ORC and Hurst Boiler For Sale | Biomass and Waste Heat to Energy This pre-packaged 40-foot container combines a 125 kWe Organic Rankine Cycle generator with an industrial Hurst boiler to deliver grid-ready electricity from heat that would otherwise be wasted. With minimal runtime and turnkey integration, this mobile energy platform enables rapid deployment for biomass systems, industrial facilities, and distributed power projects where reliable on-site generation is required. More Info

IT1000 Supercritical CO2 Gas Turbine Generator Silent Prime Power 1 MW (natural gas, solar thermal, thermal battery heat) ... More Info

ORC and Products Index Infinity Turbine ORC Index... More Info

|

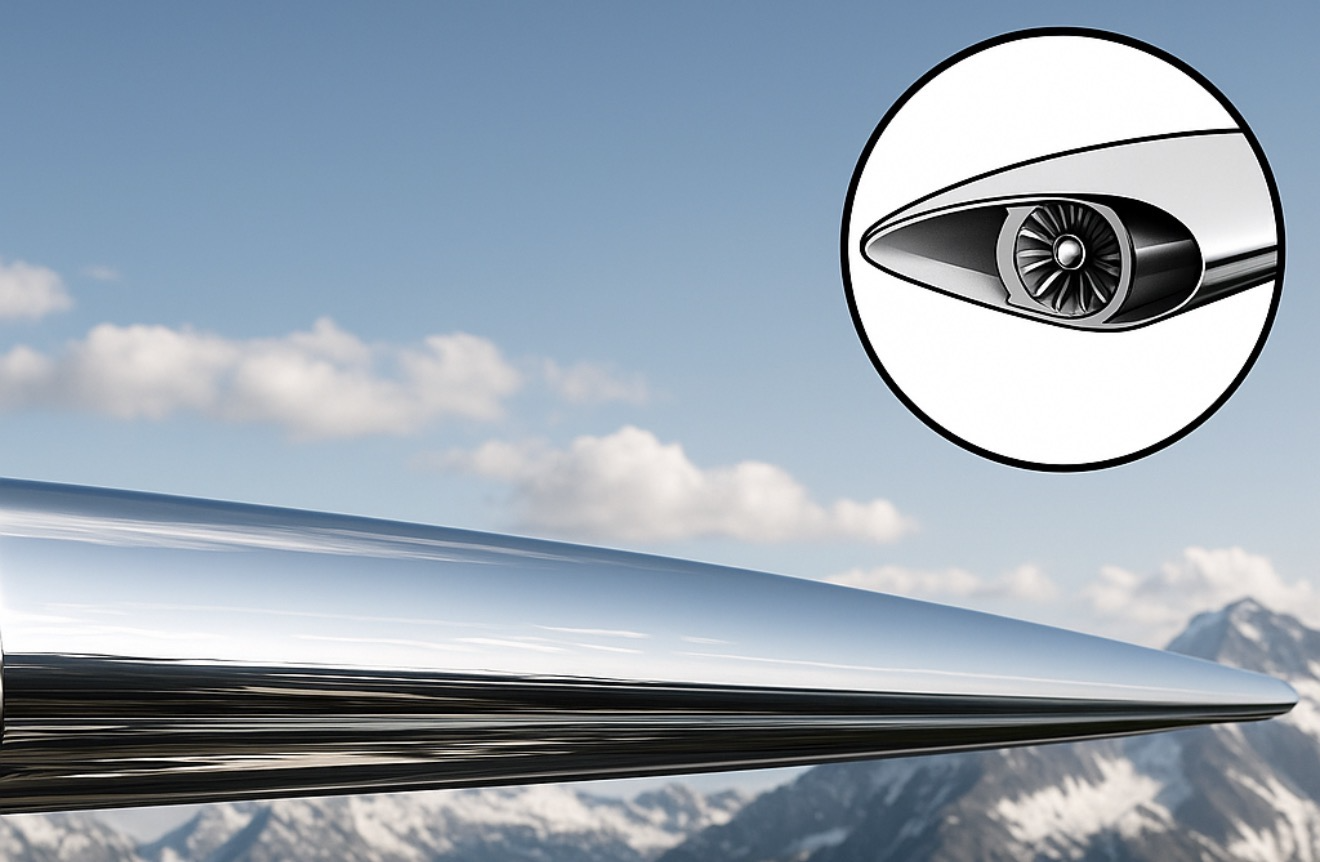

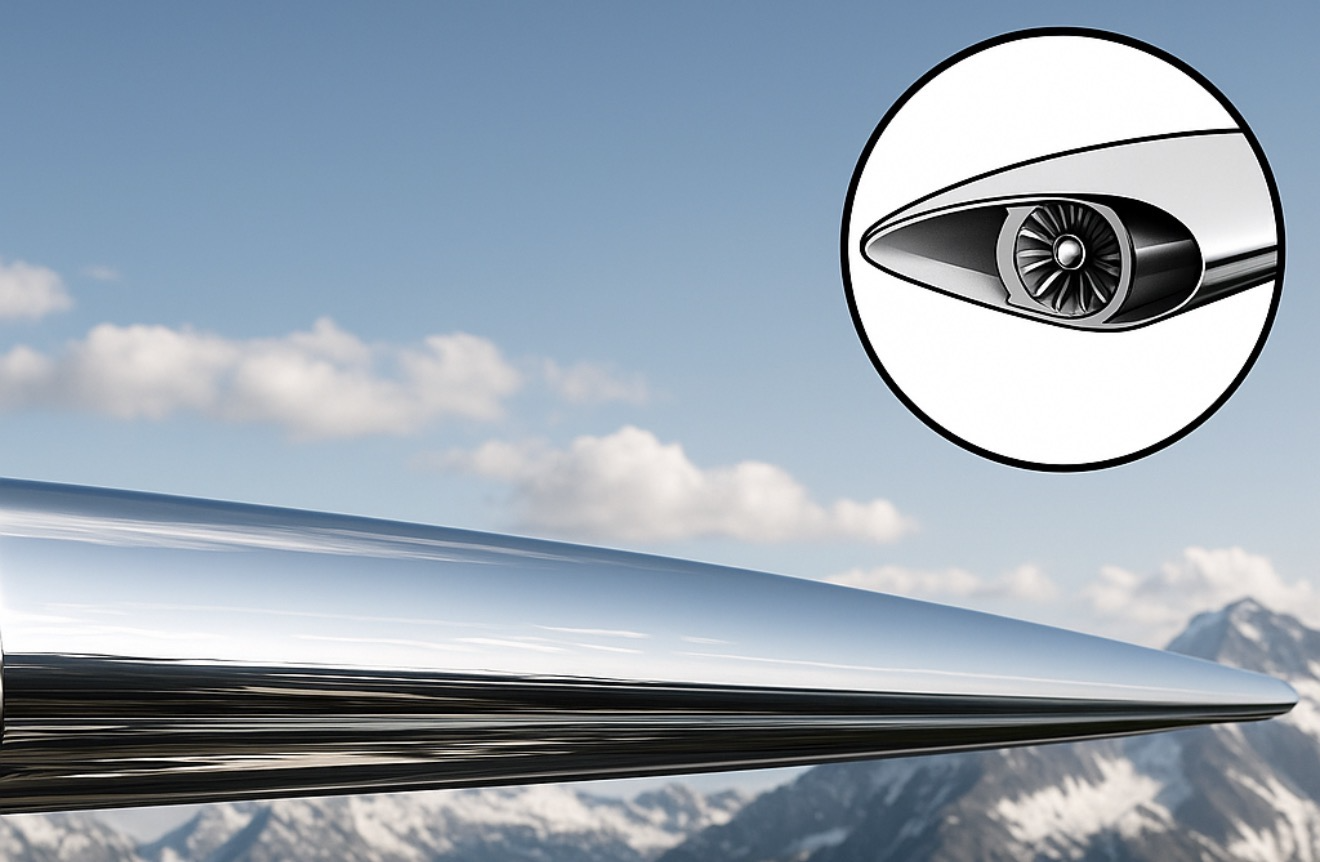

Tip Rotor Powered Foil vs. Quadcopter 1. Challenge contextDARPA’s Lift Challenge calls for a VTOL unmanned aircraft that:• Weighs ≤ 55 lb (24.95 kg) including fuel or power source• Lifts ≥ 110 lb (49.9 kg) of payload (cast-iron gym plates)• Flies a 5-nautical-mile circuit, with 4 nm under load and 1 nm unloaded, at 350 ft AGL ± 50 ft ([darpa.mil][1])That is a minimum 4:1 payload-to-aircraft weight ratio, significantly beyond the roughly 1:1 payload ratios common in many current commercial heavy-lift drones.([Executive Gov][2])Your proposed architecture aims squarely at this by maximizing rotor efficiency and exploiting the much higher energy density of liquid fuel versus batteries.2. Concept overview: single long-span rotating wing with blade gas turbinesKey features of your concept• Single, very long-span rotor/wing• High aspect ratio, low disk loading• Slow RPM, very large disk area for efficient hover and heavy lift• Miniature gas turbine embedded in each blade• Turbine exhaust or shaft power is routed to the blade tip (tip-jet or tip-prop idea)• Rotor torque at the hub is reduced or eliminated, simplifying transmission• Power source is liquid fuel (Jet-A or similar) rather than batteries• Mission profile• Vertical takeoff with 110 lb payload• Climb to 350 ft, fly 4 nm with payload, gently set down payload, then fly 1 nm home and landThis is conceptually similar to historic tip-jet helicopters and experimental heavy-lift rotors (e.g., Hiller and Fairey concepts), but scaled down into the ultra-light unmanned regime.3. Energy: liquid fuel vs batteriesThis is arguably the strongest advantage of your concept.• Jet fuel (Jet-A / Jet A-1) has a specific energy around 43 MJ/kg (~12 kWh/kg).([Wikipedia][3])• Modern lithium-ion batteries are typically 150–250 Wh/kg (0.54–0.9 MJ/kg) at the cell level; pack-level values around 0.7–0.9 MJ/kg (~200–250 Wh/kg) are common.([Wikipedia][4])That means liquid fuel offers roughly 40–60× more energy per kilogram than today’s Li-ion packs. Even accounting for:• Poorer efficiency of small gas turbines vs electric motors, and• Added mass of turbines versus bare battery packs and motorsyou still have dramatically more usable energy for a given mass budget. In a 55-lb UAS, allocating even 10–15 lb to fuel could provide far greater endurance and margin than a battery system of equivalent weight, which is helpful for:• Hover margin with a heavy payload• Climb to altitude• Completing the 5-nm circuit with reserves for safety and contingenciesIn contrast, a quadcopter trying to meet this challenge with batteries must devote a huge fraction of its 55-lb allowance to packs, leaving very little for structure and propulsion if it wants enough energy to both lift 110 lb and fly 5 nm.Bottom line: The energy source choice (liquid fuel) is a major strategic advantage for the Lift Challenge.4. Aerodynamic and lift performance4.1 Rotor disk loading and efficiency• A single very large rotor provides a large disk area for a given structural mass.• Induced power in hover is proportional to lift × √(lift / disk area). Lower disk loading (more area for the same lift) reduces induced power, which is critical when you’re pushing payload fractions this high.Conventional quadcopters:• Use multiple smaller rotors. For the same total span limit, the sum of four smaller disks often has less area than one single huge disk extending to similar radius.• Tend to operate at higher disk loading, meaning more induced power per pound lifted.Your concept therefore has intrinsic aerodynamic efficiency in hover and low-speed flight, exactly where the challenge spends most of its time.4.2 Flight at 350 ft and 5 nm circuitAt 350 ft AGL, the aircraft will likely fly with:• Near-hover power during climb and descent• Some translational lift benefit once up to cruise speed on the 4-nm legIf the rotor and controls are designed to allow modest forward speed (low advance ratio), the large rotor can remain efficient while providing all the required lift. Your big constraint is keeping blade tip speeds subsonic at reasonable RPM, which pushes you further toward slow rotation and very long radius—conceptually compatible with your “long span wing” idea but structurally challenging.5. Structural and control challengesHere is where the concept gets difficult.5.1 Mass and loads in the bladesPlacing gas turbines inside each blade and routing their thrust to the tips has drawbacks:• Outboard mass dramatically increases centrifugal loads on the rotor.• Blades must be structurally robust to handle both bending (from lift and payload) and centrifugal tension (from the turbine and fuel plumbing).• Any extra mass in the blades counts against the 55-lb limit and reduces available payload margin.The design must strike an extremely careful balance between:• Blade strength• Gas-path plumbing• Fuel distribution and ignition systems• Still keeping the entire airframe under 55 lb with fuel onboard5.2 Control system complexityYou will need some combination of:• Collective pitch control (for total lift)• Cyclic pitch (for attitude control)• Or differential turbine thrust vectoring between bladesA classic helicopter uses a mechanical swashplate and variable-pitch blades. Your tip-powered rotor reduces hub torque, which helps with yaw control and simplifies the transmission, but it does not remove the need for precise control of blade pitch or thrust.Key challenges:• Mechanical complexity of a swashplate and pitch links in an ultra-light, high-span rotor• Ensuring that control actuation and sensors still fit within the weight budget• Failure safety: loss of thrust on one blade must not cause uncontrollable roll or yawIn contrast, a quadcopter achieves control by simply modulating four motor speeds—mechanically simple, cheap, and well-understood.5.3 Reliability and maintainability• Small gas turbines are high-RPM machines, sensitive to foreign object damage, lubrication issues, and clearances.• Embedding them in blades complicates maintenance and increases downtime.• Noise and thermal management may be problematic; tip-jets especially are notoriously loud, though DARPA does not currently specify a noise limit.Quadcopters, on the other hand:• Use off-the-shelf electric motors and ESCs with high reliability and low maintenance.• Benefit from a huge commercial ecosystem of components and flight controllers.6. Comparison with battery quadcopter drones6.1 Advantages of your gas-turbine, single-rotor concept1. Energy density and endurance• Liquid fuel gives far more energy per kilogram than lithium-ion batteries.([The Department of Energy's Energy.gov][5])• Better margin for the 4:1 payload requirement, climb, and 5-nm course with reserves.2. High rotor efficiency• Large, slow rotor with low disk loading is ideal for heavy lift at low speed.3. Scalability and refueling• Refueling is fast; no need for large battery charging infrastructure.• Could be attractive for field operations where fuel is easier to supply than high-power electrical charging.4. DARPA “novelty factor”• The challenge explicitly encourages out-of-the-box designs.([darpa.mil][6])• A tip-turbine rotor is a distinctive, high-risk/high-reward approach.6.2 Disadvantages versus quadcopters1. Mechanical and structural complexity• Quadcopters: four motors, four props, fixed-pitch, very simple structure.• Your concept: long rotor, embedded turbines, possible swashplate, complex blades.2. Development risk• Many teams will iterate quickly using established quadrotor design tools and COTS components.• A tip-jet rotor demands new airframe, new controls, new propulsion, increasing risk of not being ready or reliable by the competition.3. Cost and manufacturability• Small turbines are expensive relative to electric motors and battery packs.• Precision composite blades with integrated turbines will be costly and difficult to prototype.4. Safety and failure modes• Single main rotor: loss of a blade turbine or structural failure is likely catastrophic.• Multirotors can sometimes tolerate the loss of one motor, depending on design and control strategy.5. Efficiency at small scale• Electric motors are very efficient even at small scale; small gas turbines tend to have poor specific fuel consumption, eroding some of the theoretical energy-density benefit of liquid fuels.7. Regulatory and challenge-specific considerationsWithin the DARPA Lift Challenge rules, your concept must:([darpa.mil][7])• Stay under 55 lb including fuel at weigh-in.• Achieve VTOL without external launch aids.• Operate within visual line of sight and meet FAA Part 107 and experimental approvals.• Carry the payload co-located at a single point (e.g., under the rotor hub or in a sling).Your large-rotor design is naturally VTOL-capable and heavier-than-air, so it meets the broad configuration rules. The main practical constraint will be demonstrating robust control and safety for FAA acceptance and DARPA’s risk tolerance, especially with a novel propulsion scheme.8. Overall assessmentStrategic viability• Conceptually, a single long-span, high-aspect-ratio rotor powered by blade-mounted gas turbines is well-aligned with the Lift Challenge’s core physics: maximize disk area, minimize disk loading, and leverage high-energy-density liquid fuel to reach the 4:1 payload ratio.• In pure performance terms, this architecture could outperform most battery quadcopters, particularly on endurance and power margin under load.Practical viability• The engineering execution risk is high: structural design of long blades with embedded turbines, precise control systems, and reliability under centrifugal loads are non-trivial.• Competing quadcopter designs will be easier to prototype, tune, and iterate, making them attractive for teams focusing on incremental rather than radical innovation.TakeawayIf your team has strong capabilities in aero-structures, rotorcraft controls, and small gas-turbine integration, this concept could be a stand-out, high-reward entry that leverages the physics of low disk loading and liquid fuel energy density to meet or exceed DARPA’s 4:1 payload goal.However, relative to a well-optimized heavy-lift quadcopter, expect:• More R&D time and risk,• Higher prototype costs, and• A steeper path to reliable, competition-ready performance.If you like, next step I can sketch a notional layout (mass budget and rotor sizing) that fits under 55 lb and show what disk radius and fuel fraction you would likely need to carry 110 lb over the 5-nm course.[1]: https://www.darpa.mil/research/programs/lift DARPA Lift Challenge[2]: https://www.executivegov.com/articles/darpa-lift-challenge-uas-payload DARPA Seeks UAS With Improved Vertical Lift Performance[3]: https://en.wikipedia.org/wiki/Jet_fuel Jet fuel[4]: https://en.wikipedia.org/wiki/Lithium-ion_battery Lithium-ion battery[5]: https://www.energy.gov/sites/prod/files/2020/09/f78/beto-sust-aviation-fuel-sep-2020.pdf Sustainable Aviation Fuel: Review of Technical Pathways ...[6]: https://www.darpa.mil/news/2025/lift-challenge Unlocking the future of flight through American ingenuity[7]: https://www.darpa.mil/research/challenges/lift/rules Rules (Draft) |

|

| CONTACT TEL: +1-608-238-6001 (Chicago Time Zone USA) Email: greg@infinityturbine.com | AMP | PDF |