NVIDIA H100 GPU Precious Metals Recovery

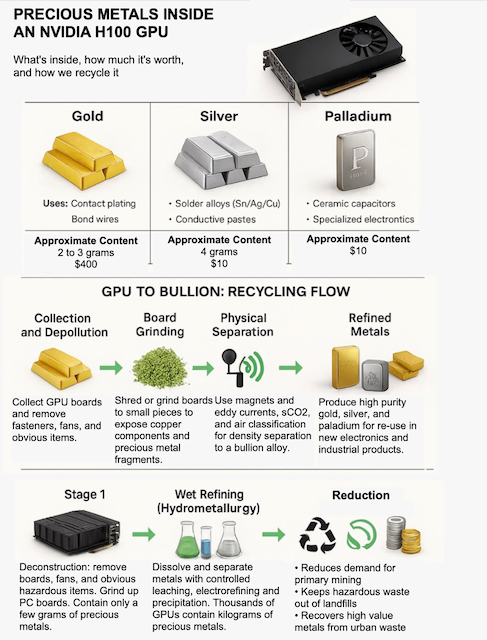

1. IntroductionHigh end data center GPUs like the NVIDIA H100 are built with advanced semiconductor processes, dense multilayer circuit boards, and high quality connectors. They also contain small but valuable quantities of precious metals, mostly gold, plus smaller amounts of silver and palladium.For a single H100, the precious metal value is only a small fraction of the several tens of thousands of dollars purchase price, but across thousands of boards, recovery can become economically meaningful. At the same time, proper recycling keeps toxic and valuable materials out of landfills.This article introduces approximate precious metal quantities per H100, explains why these metals are used, and then describes a practical industrial style recycling flow, starting with mechanical grinding and ending with refined metals.2. Precious metals in an NVIDIA H100 (approximate)No public bill of materials exists that lists the exact grams of gold, silver, and palladium in an H100. However, we can make reasonable estimates based on:1. Typical content in high end GPUs and server boards.2. Known uses of these metals in electronics.The approximate ranges below are intended as engineering order of magnitude figures, not exact values.2.1 Main precious metalsGold (Au)Used for:1. Edge connector plating.2. BGA pad plating and some internal vias.3. Wire bonding inside packages and modules.4. Some high reliability connectors.Estimated mass per H100:Low estimate: 2 gHigh estimate: 4 gWorking midpoint: 3 gSilver (Ag)Used for:1. Lead free solder alloys (Sn Ag Cu).2. Some conductive pastes and epoxies.3. Occasionally in specialty contacts.Estimated mass per H100:Low estimate: 2 gHigh estimate: 5 gWorking midpoint: 3.5 gPalladium (Pd)Used for:1. Multilayer ceramic capacitors (palladium rich internal electrodes in some designs, though modern parts often use nickel).2. Some plating and semiconductor structures.Estimated mass per H100:Low estimate: 0.2 gHigh estimate: 0.5 gWorking midpoint: 0.35 g2.2 Approximate value snapshotIf we use rough spot prices for illustration and multiply by the midpoint estimates:Example spot prices (illustrative, not exact market quotes):Gold price per gram: about 130 USDSilver price per gram: about 1.6 USDPalladium price per gram: about 45 USDEstimated values per H100:Gold value3 g × 130 USD per g ≈ 390 USDSilver value3.5 g × 1.6 USD per g ≈ 5.6 USDPalladium value0.35 g × 45 USD per g ≈ 15.8 USDTotal precious metal value per H100 (gold plus silver plus palladium) is therefore in the neighborhood of:About 410 to 420 USD, dominated by gold.These numbers will vary with market prices and the exact board configuration, but they give a realistic sense of scale.3. Why these metals are usedGoldGold does not oxidize in normal environments, has excellent conductivity, and forms reliable, low resistance, long life connections. It is used in thin plating layers on contacts, pads, and bond wires, where reliability is more important than the raw metal cost.SilverSilver has the highest electrical conductivity of any metal. In electronics it is commonly used in solder alloys, especially in Sn Ag Cu formulations. Even small silver percentages in solder add up over a large board populated with thousands of joints.PalladiumPalladium is used in specialty capacitors (historically in silver palladium ceramics) and in some plating and catalytic processes in semiconductor manufacturing. The quantity per board is small but high value per gram.4. Overview of an H100 recycling processRecycling an H100 for precious metals is not as simple as desoldering a few parts. Industrial scale processes treat the board as part of a mixed electronic scrap stream. A typical process has multiple stages:Stage 1Collection and depollution1. Collect end of life GPUs and server boards.2. Remove obvious hazardous items if present (large batteries, cooling fluids, etc.).3. Separate large mechanical items (heatsinks, fans, brackets) to reduce mass going into shredding.For H100 type hardware, you would typically remove the massive heatsink and cold plate assembly first. The heatsink metal (usually aluminum or copper) can then be recycled through non precious metal scrap streams.Stage 2Mechanical size reduction1. Shred or grind the boards into small pieces, typically to a few millimeters in size.2. Aim for a consistent particle size to improve downstream separation.3. Control dust and emissions, as fine particulate can be hazardous.At this point, the ground material contains a mix of:1. Fiberglass and resin.2. Copper foils and power planes.3. Solder.4. Component bodies (ceramics, plastics, silicon).5. Precious metal bearing fragments (gold plated contacts, small bits of wire bond, etc.).Stage 3Physical separation (pre concentration)The goal here is to concentrate metals and reduce the volume of non metallic waste before chemical processing.Common steps include:1. Magnetic separationSeparate ferrous metals (iron, steel fragments from screws, brackets, and some components).2. Eddy current separationSeparate non ferrous metals (aluminum, copper, some brass pieces) from non metallics.3. Density or gravity separationUse shaking tables or fluidized systems to further concentrate metal rich fractions.4. Air classificationUse air flow to separate light dust and fiberglass from heavier metal containing particles.After this stage, you typically have:1. A metal rich fraction for further metallurgical treatment.2. A non metallic fraction (fiberglass, resin, plastics) which may be landfilled, incinerated, or used as filler material depending on local regulations.Stage 4Pyrometallurgical treatment (smelting)The metal rich fraction then goes to a smelter, often one designed for electronic scrap or copper concentrates.General steps:1. Charge the furnace with a mix of electronic scrap, fluxes, and sometimes primary concentrates (such as copper ore).2. Heat to high temperature.3. Base metals such as copper, tin, lead, and iron form molten phases.4. Precious metals (gold, silver, palladium, platinum group metals) preferentially dissolve into a copper or lead rich phase.Outputs from smelting typically include:1. A copper or lead bullion enriched with gold, silver, and palladium.2. Slag (glass like waste) which can contain some residual metals.3. Off gases that require scrubbing.H100 boards, like other high end electronics, are excellent feedstock because their copper content helps carry precious metals into the bullion phase.Stage 5Hydrometallurgical refiningThe bullion then undergoes refining steps, often in multiple stages.Typical sequence:1. Electrorefining of copper or lead, which separates base metals and leaves precious metals in slimes.2. Leaching of slimes with carefully chosen acids or chlorides to selectively dissolve gold, silver, and palladium.3. Precipitation or electrolytic recovery of each metal.For example, a simplified outline for gold and silver:1. Use a chloride based lixiviant (e.g., aqua regia in some classical flows or other industrial chloride systems) to dissolve gold and some silver.2. Precipitate gold using reducing agents or electro winning.3. Treat the remaining solution to recover silver, often as silver chloride or via electro refining.Palladium and other platinum group metals are usually recovered from specific refining circuits that handle the anode slimes or specific solution lines, using selective precipitation or solvent extraction.Stage 6Final refining and productThe recovered metals then go through final refining to reach saleable purity.Examples:1. Gold refined to 99.9 percent or higher, cast into bars or granules.2. Silver refined to similar purity for industrial, investment, or photographic uses.3. Palladium refined for catalytic converters, electronics, or other industrial uses.At the end of this chain, the original H100 is reduced to:1. Refined metals (including non precious copper, tin, etc.).2. Non metallic residues (treated slag, glassy materials, fillers).3. Emissions that have been captured and processed according to environmental regulations.5. Practical notes for H100 scale recyclingA few key realities:1. Single unit economicsOne H100 only contains on the order of a few hundred dollars worth of precious metals. The recycling process only becomes economical at scale, when many boards are processed as part of larger electronic scrap streams.2. Value in copper and other base metalsA significant fraction of the monetary value can be in copper and other base metals. For server class boards, copper can be a major value driver alongside gold.3. Regulatory and environmental considerationsIndustrial recycling requires serious environmental control, especially for fumes, dust, and acid effluents. It is not practical or safe to replicate full processes at small scale.4. Design for recyclabilityOver time, there is potential to design high end GPUs and server boards with more straightforward material separation, reducing hazardous components and improving the yield and efficiency of recycling.6. ConclusionAn NVIDIA H100 contains only a few grams of gold, a few grams of silver, and fractions of a gram of palladium, but across thousands of units these add up to meaningful quantities of precious metals. Recovering those metals requires:1. Mechanical reduction of the board.2. Physical separation of non metallics from metal rich fractions.3. High temperature smelting to concentrate precious metals into bullion.4. Hydrometallurgical refining to separate and purify individual metals.From a materials point of view, GPUs like the H100 are rich urban ore. Understanding the approximate quantities and the recycling pathway helps frame future discussions on data center hardware lifecycles, environmental impact, and the long term value locked inside high performance computing hardware.