Pin Stack Ferrofluid Cooling: A Breakthrough in Thermal Management and Energy Storage Compared to Fin Stacks

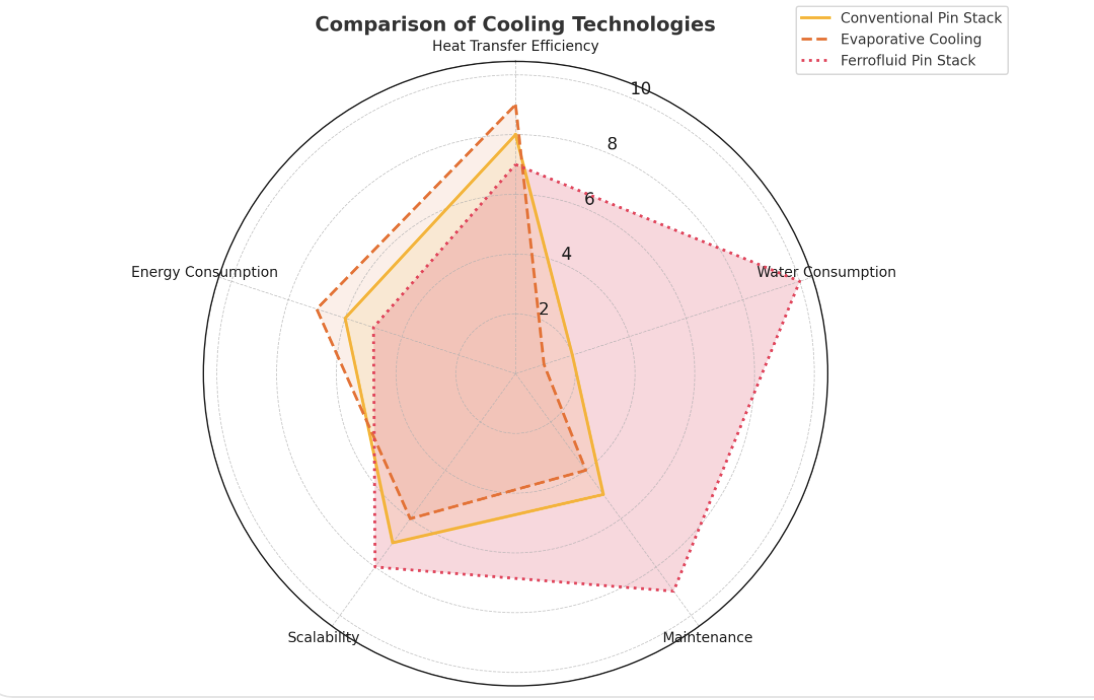

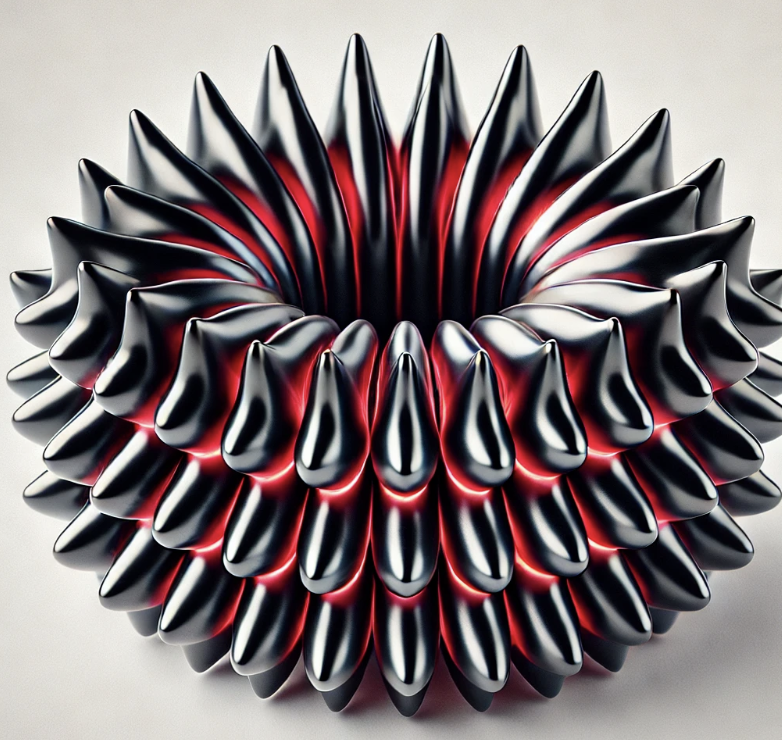

Introduction Thermal management is a critical challenge in data centers, power electronics, and industrial processes, where efficient cooling can significantly impact performance and energy consumption. Conventional cooling towers rely on water over fin stacks to enhance heat dissipation. However, water evaporation losses and scaling issues limit efficiency. A novel approach replaces water with ferrofluid, a magnetic liquid capable of forming dynamic surface structures under a controlled electromagnetic field. This technology not only enhances cooling efficiency but also has potential as an advanced electrode for flow batteries, providing a dual-use application in energy storage.The Science Behind Pin Stack Ferrofluid Cooling Pin stack cooling increases the surface area for heat dissipation by creating structured turbulence in fluid flow. Traditionally, cooling towers use structured fin stacks immersed in flowing water to achieve this effect. By replacing water with ferrofluid, the cooling process can be actively controlled by applying a cyclic electromagnetic field, creating dynamic surface spikes. The ferrofluid spikes constantly reshape under magnetic field modulation, maximizing heat transfer through: • Increased surface area due to dynamic pattern formation. • Enhanced convection from continuous movement and fluid mixing. • No evaporation losses, unlike traditional water cooling systems. • Potential self-cleaning properties due to fluidic motion. However, ferrofluid’s lower thermal conductivity compared to water is a limitation that can be mitigated through hybrid nanoparticle formulations, such as graphene-enhanced ferrofluids.Integration as a Flow Battery Electrode Beyond cooling, the same ferrofluid and electromagnetic pin stack arrangement can function as an electrode in a flow battery. Flow batteries store and release energy through electrolyte solutions circulating between two electrodes. Ferrofluids can serve as active electrode surfaces by dynamically restructuring under a magnetic field, increasing reaction kinetics and charge transfer efficiency. Potential benefits in flow battery applications include: • Higher surface area for electrochemical reactions due to adaptive spike formations. • Reduced electrode fouling from self-regulating ferrofluid motion. • Improved mass transport as continuous movement enhances ion diffusion. • Scalability for grid-scale and renewable energy storage applications. This integration presents a unique opportunity for a single system to provide both thermal management in data centers and energy storage in renewable power systems.Challenges and Future Research Despite the promise of this technology, several challenges need to be addressed: 1. Thermal Conductivity Limitations: Ferrofluids generally have lower heat capacity than water, requiring further enhancements such as carbon nanotube (CNT) or graphene additives. 2. Energy Cost of Magnetic Cycling: Maintaining an electromagnetic field for ferrofluid manipulation requires energy. The trade-off between improved cooling performance and additional power consumption must be optimized. 3. Long-Term Ferrofluid Stability: Over time, nanoparticles in ferrofluids can aggregate, affecting performance. Research into surfactant stability and nanoparticle dispersion is essential. 4. Material Compatibility: Ferrofluids may cause corrosion or deposition issues in certain cooling tower materials, necessitating further compatibility studies. Future research will focus on optimizing nanoparticle compositions, electromagnetic field efficiencies, and system scalability for widespread industrial adoption.Applications and Market Potential This dual-purpose ferrofluid technology has applications across multiple industries, including: • Data Centers: Enhancing cooling efficiency without water loss or scaling issues. • Renewable Energy Storage: Serving as a dynamic electrode in grid-scale flow batteries. • Power Electronics: Improving cooling efficiency in high-performance computing and industrial power systems. • Aerospace and Space Systems: Providing non-evaporative cooling in vacuum environments. By combining ferrofluid cooling with energy storage functionality, this technology could significantly reduce energy costs, improve thermal management, and contribute to sustainable power solutions.Scientific References 1. Jafari, M., et al. (2020). Enhancement of Convective Heat Transfer Using Ferrofluids: A Review. Renewable and Sustainable Energy Reviews, 125, 109817. 2. Singh, R., & Kumar, A. (2022). Magnetically Driven Heat Transfer and Fluid Flow of Ferrofluids: Applications in Cooling Systems. Applied Thermal Engineering, 214, 118849. 3. Almeida, L., et al. (2019). Nanofluid and Ferrofluid Applications in Heat Transfer: A Critical Review. International Journal of Thermal Sciences, 142, 106–118. 4. Zhao, H., et al. (2021). Advances in Flow Battery Electrodes: Nanostructures and Functional Materials. Energy Storage Materials, 34, 564–582. 5. Chen, X., et al. (2023). Dynamic Magnetic Fluid Electrodes for High-Efficiency Energy Storage. Journal of Electrochemical Energy Conversion and Storage, 20(3), 032006. This innovative approach to ferrofluid-based pin stack cooling presents a compelling opportunity for high-efficiency heat dissipation and energy storage, positioning it as a key technology for the future of sustainable energy systems.