Introducing the ROT12 Turbine Assembly within the versatile IT10 System specifically designed for Organic Rankine Cycle and CAES (Compressed Air Energy Storage) up to 300 psi.

INFINITY TURBINE | SALES | DESIGN | DEVELOPMENT | ANALYSIS CONSULTING

TEL: +1-608-238-6001 (Chicago Time Zone ) Email: greg@infinityturbine.com

ElectraTherm 125 kWe ORC and Hurst Boiler For Sale | Biomass and Waste Heat to Energy This pre-packaged 40-foot container combines a 125 kWe Organic Rankine Cycle generator with an industrial Hurst boiler to deliver grid-ready electricity from heat that would otherwise be wasted. With minimal runtime and turnkey integration, this mobile energy platform enables rapid deployment for biomass systems, industrial facilities, and distributed power projects where reliable on-site generation is required. More Info

IT1000 Supercritical CO2 Gas Turbine Generator Silent Prime Power 1 MW (natural gas, solar thermal, thermal battery heat) ... More Info

ORC and Products Index Infinity Turbine ORC Index... More Info

Introducing the ROT12 Turbine Assembly within the versatile IT10 System specifically designed for Organic Rankine Cycle and CAES (Compressed Air Energy Storage) up to 300 psi. |

|

|

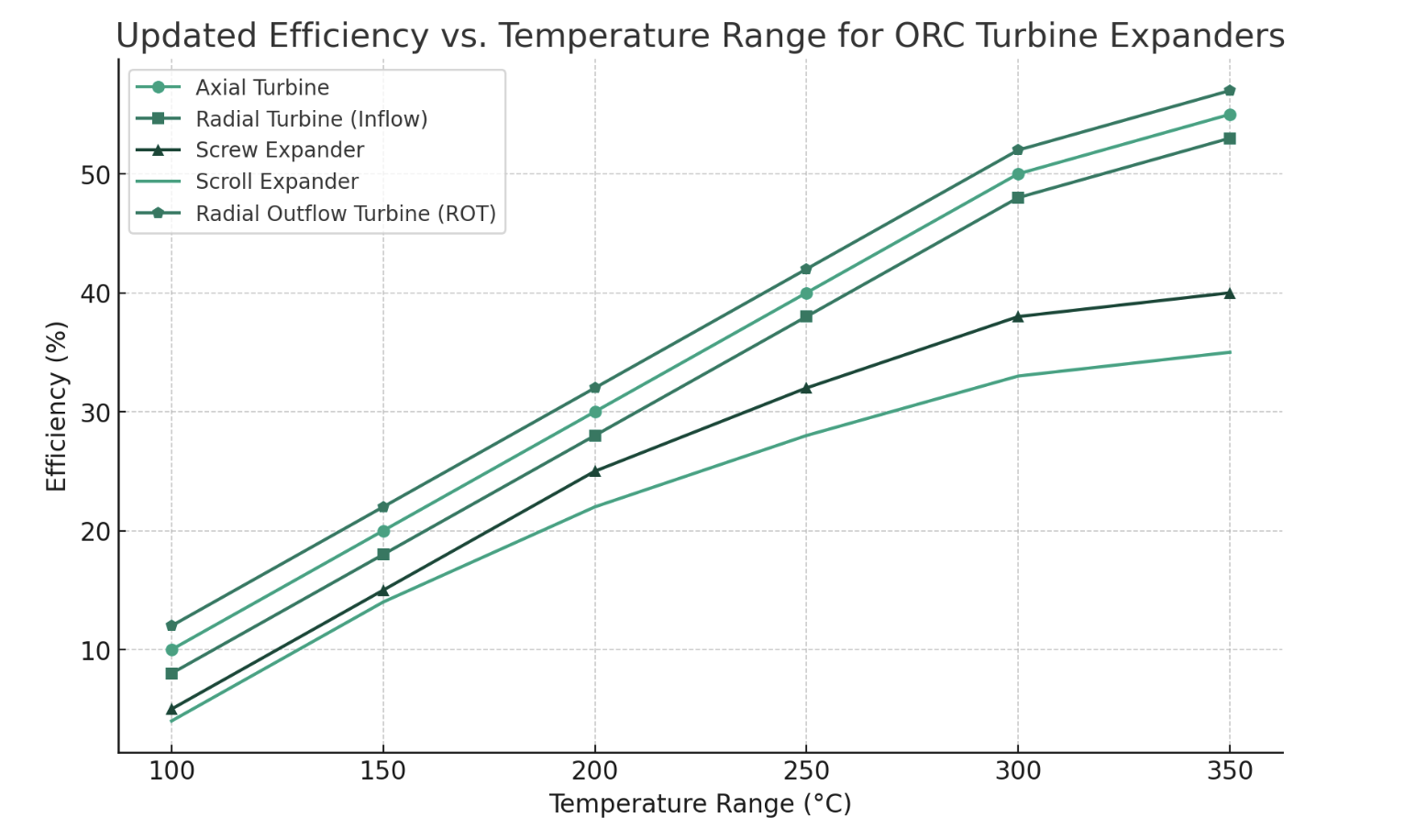

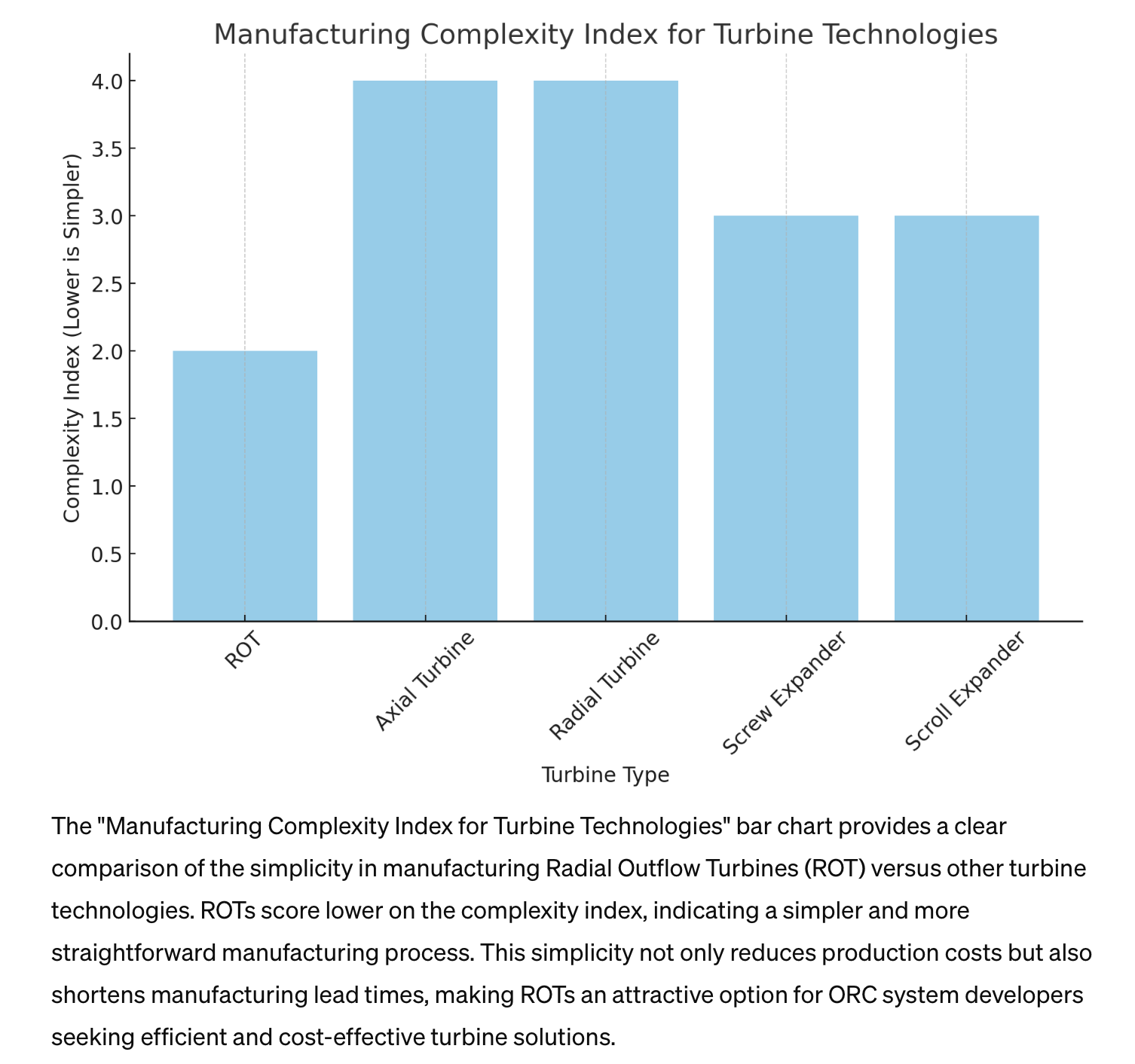

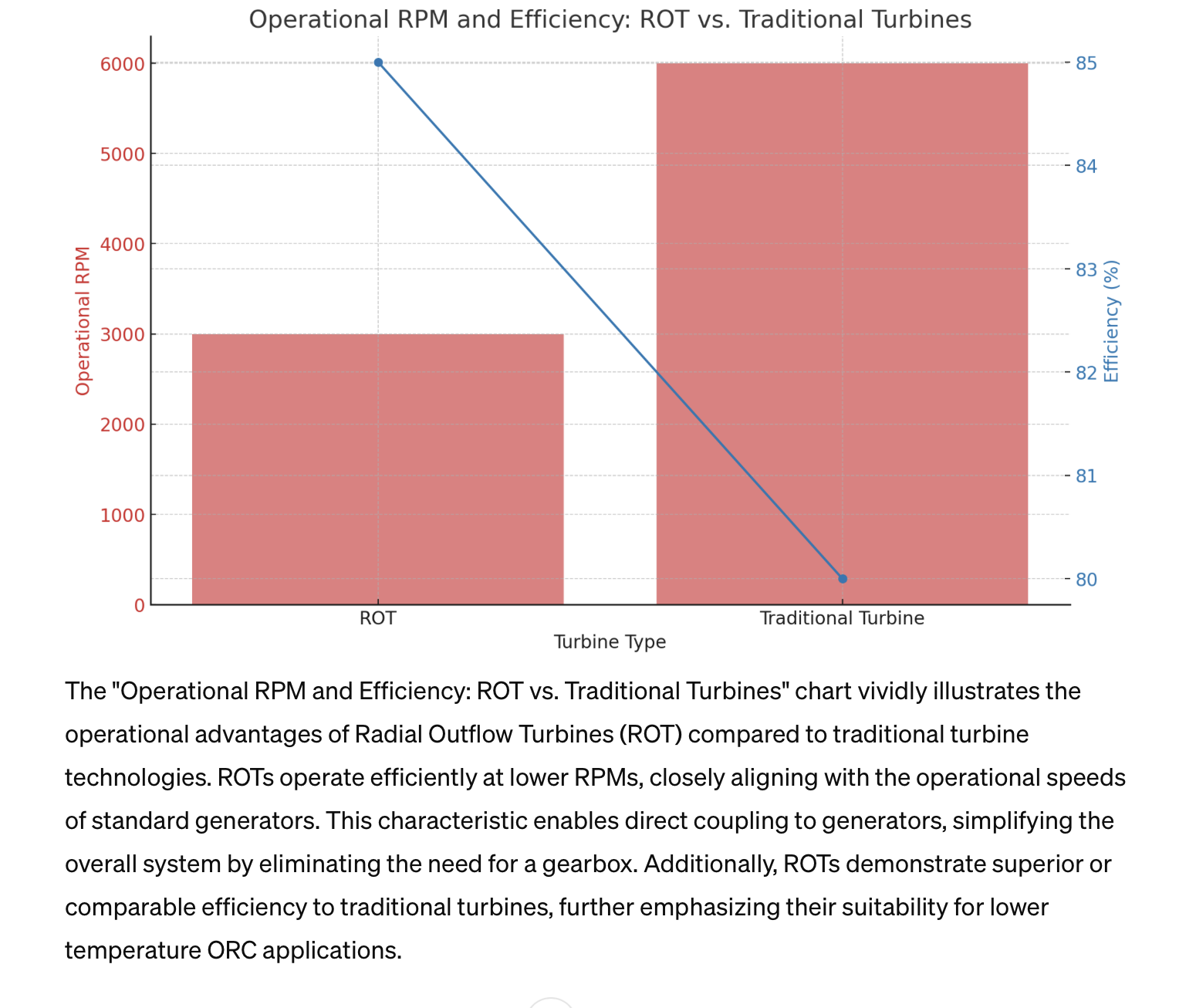

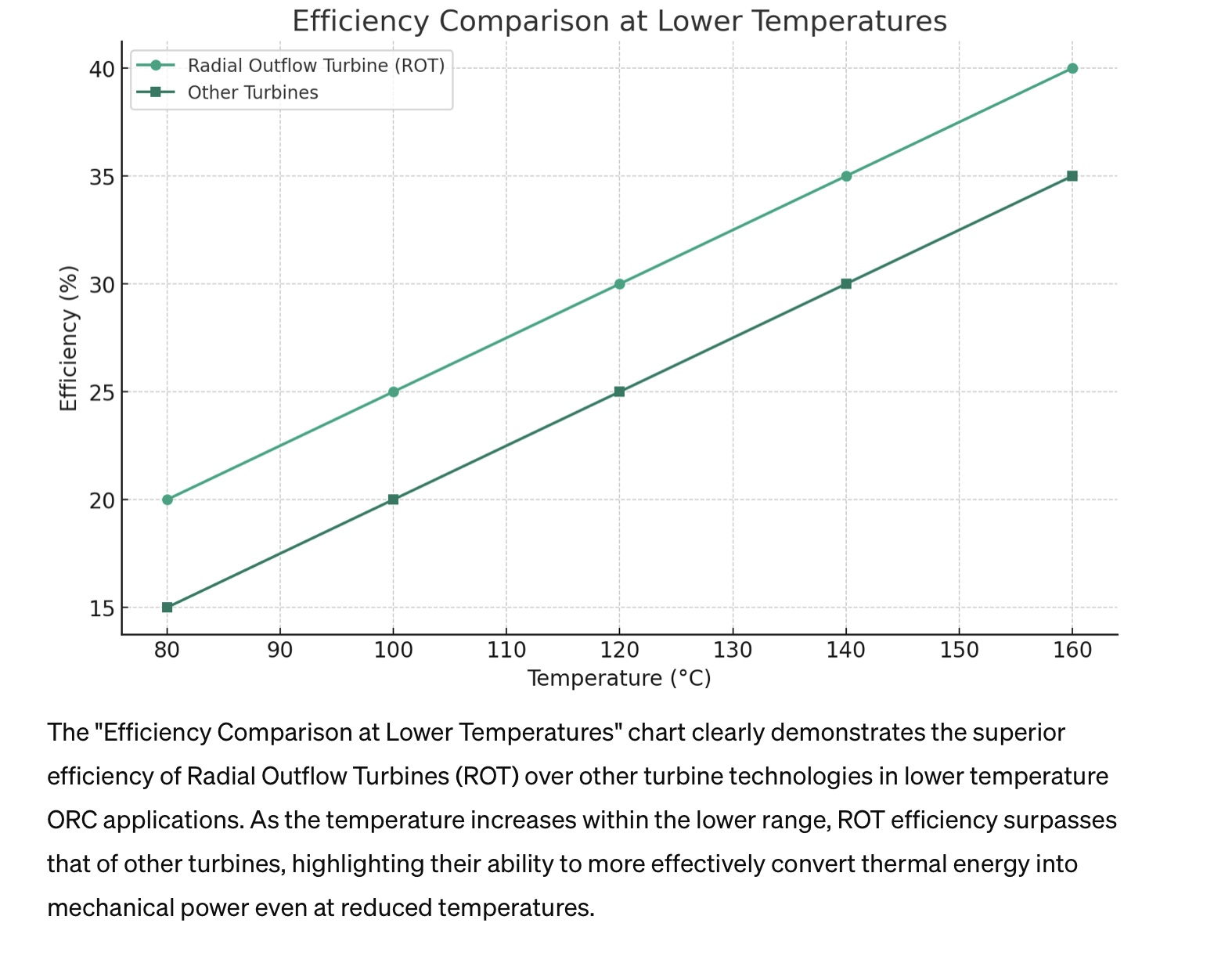

Understanding Organic Rankine Cycle (ORC) Turbine Expander Technologies Comparing various Organic Rankine Cycle (ORC) turbine expander technologies, we'll cover the basics of ORC systems, delve into the types of turbine expanders used, and compare their performances, efficiencies, applications, and suitability for different energy sources. We will also incorporate charts to visualize key differences and performance metrics. The Organic Rankine Cycle (ORC) is a thermodynamic process that converts thermal energy into mechanical power, which can then be transformed into electricity. Unlike traditional Rankine cycles that use water as the working fluid, ORC systems use organic fluids, allowing them to operate efficiently at lower temperatures and with smaller temperature differences. This capability makes ORC technology particularly suitable for renewable energy sources such as biomass, geothermal, and waste heat recovery.Please click on the link to read the articles...Understanding Organic Rankine Cycle (ORC) Turbine Expander Technologies |

|

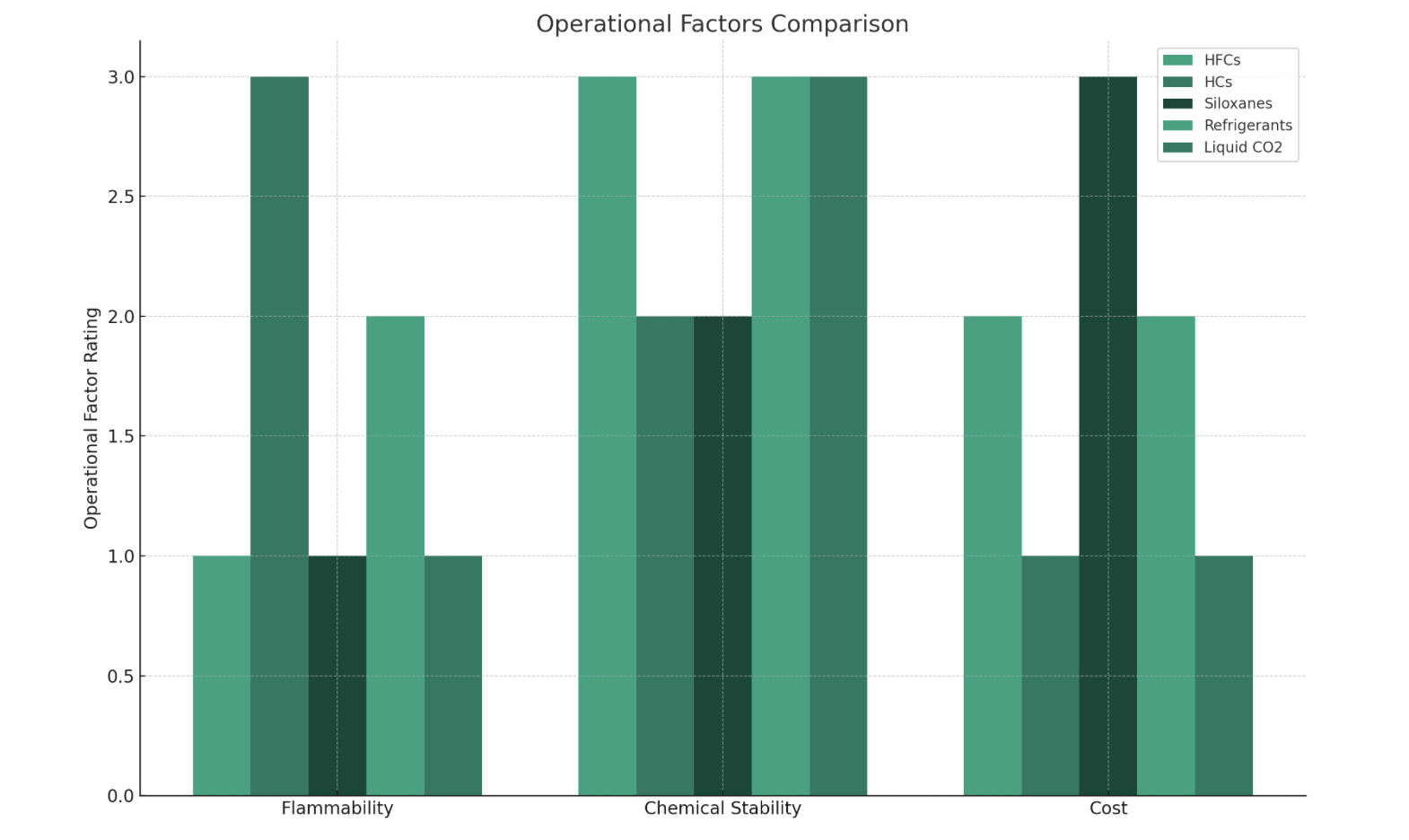

Comparing Organic Rankine Cycle Working Fluids to Liquid CO2 in the 40-150 C Range The Organic Rankine Cycle (ORC) is a highly versatile technology for converting low-grade heat into electricity. A critical factor in the efficiency and effectiveness of ORC systems is the choice of working fluid. Traditional ORC systems utilize a variety of organic fluids, each with its unique properties and performance characteristics. However, recent advancements have introduced liquid carbon dioxide (CO2) as a potential working fluid, particularly in the moderate temperature range of 40-150°C. This article explores the comparison of various organic working fluids against liquid CO2 within this temperature range, highlighting efficiency, environmental impact, and operational advantages and disadvantages.Read more about ORC working fluids with link below...Comparing Organic Rankine Cycle Working Fluids to Liquid CO2 |

|

|

|

| CONTACT TEL: +1-608-238-6001 (Chicago Time Zone USA) Email: greg@infinityturbine.com | AMP | PDF |